Quick-setting quick-hardening high-strength low-carbon cement clinker as well as preparation method and application thereof

A low-carbon cement clinker and content technology, applied in the field of cement clinker, can solve the problems of raw material limitation, uneconomical, and difficulty in large-scale production, and achieve low chloride ion content, significant thixotropy, and high compressive strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

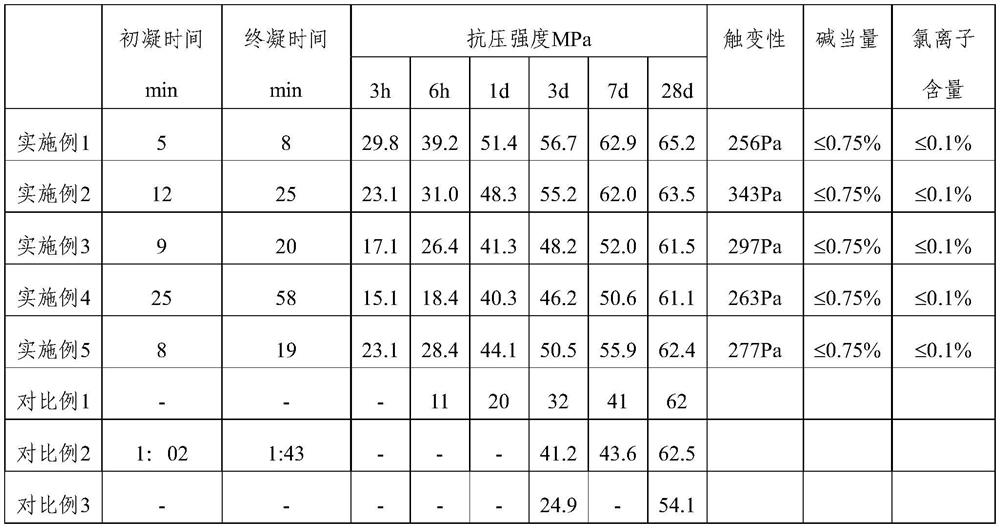

Examples

preparation example Construction

[0074] As one of the specific embodiments of the present invention, the preparation method of the quick-setting quick-hardening low-carbon cement clinker includes:

[0075] (1) Use calcareous material, gypsum and silicon-aluminum material to weigh according to a given weight ratio, and then use a ball mill to grind until the particles larger than 90 microns in the mixed raw meal are less than 10%;

[0076] (2) Take out the mixed raw meal, add a small amount of water to the mixed raw meal, after stirring evenly, use a press to press into a test cake with a thickness of about 2 cm and a diameter of 5 cm;

[0077] (3) Put the test cake into a high-temperature electric furnace for calcination, the heating rate of the electric furnace is 15°C / min, and calcine at a constant temperature of 1250-1350°C for 15-60min;

[0078] (4) Slowly cool the clinker in the electric furnace to 1100°C at a rate of about 20°C / min, take it out, and quickly cool it to room temperature at a rate of not l...

Embodiment 1

[0081] A preparation method of cement clinker, the steps are as follows:

[0082] (1) Use low-grade limestone, desulfurized gypsum, molybdenum tailings and industrial solid waste mineralizer containing calcium fluoride to mix according to the mass fraction of 72.5%: 20%: 7%: 0.5%, and use a ball mill to grind to the mixture Particles larger than 90 microns in less than 1% of the total weight;

[0083] (2) Add a small amount of water to the mixture, stir it evenly, and press it into a test cake with a thickness of about 2cm and a diameter of 5cm with a press;

[0084] (3) Put the test cake into a high-temperature electric furnace for calcination. The heating rate of the electric furnace is 15°C / min, and it is calcined at 1330°C for 55 minutes. Then it is cooled in the electric furnace to 1100°C at a cooling rate of about 20°C / min, and then cooled rapidly. to room temperature.

[0085] After testing, the crystalline phase accounts for 88.7% and the amorphous phase accounts for...

Embodiment 2

[0095] A preparation method of cement clinker, the steps are as follows:

[0096] (1) Adopt papermaking lime mud, desulfurization gypsum, gold tailings and industrial solid waste mineralizer containing calcium fluoride and zinc oxide to mix according to the ratio of 69%: 19%: 10%: 2%, and grind to Particles larger than 90 microns in the mixture are less than 1% of the total weight;

[0097] (2) Then, add a small amount of water in the mixture, after stirring evenly, press it into a test cake with a thickness of about 2cm and a diameter of 5cm with a press;

[0098] (3) Then, put the test cake into a high-temperature electric furnace for calcination. The heating rate of the electric furnace is 15°C / min, and it is calcined at 1320°C for 35 minutes, and then cooled to 1100°C in the electric furnace at a cooling rate of about 20°C / min, and then Rapid cooling to room temperature;

[0099] After testing, the crystalline phase accounts for 90.4% and the amorphous phase accounts for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com