High-iron-phase Portland cement product and preparation method thereof

A technology of Portland cement and high-iron phase, which is applied in the field of building materials, can solve problems such as the inability to prepare ultra-high-strength cement concrete carbonized products, and achieve the effects of short production cycle, wide source of raw materials, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] A first aspect of the invention provides a method for preparing a high-speed rail-phase silicate cement product, comprising the steps of:

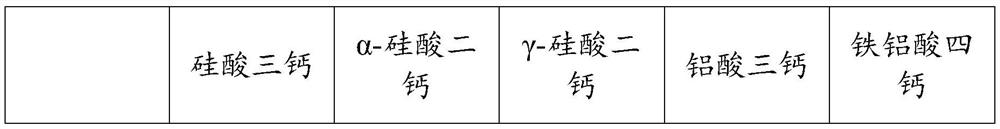

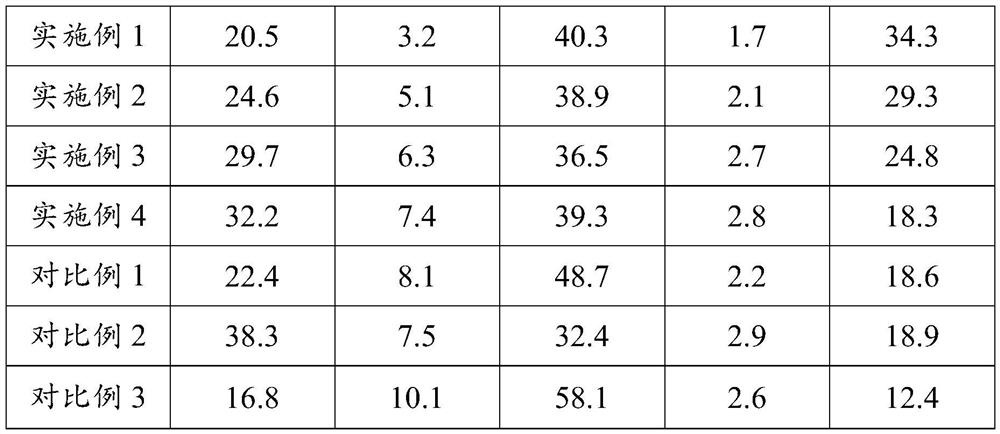

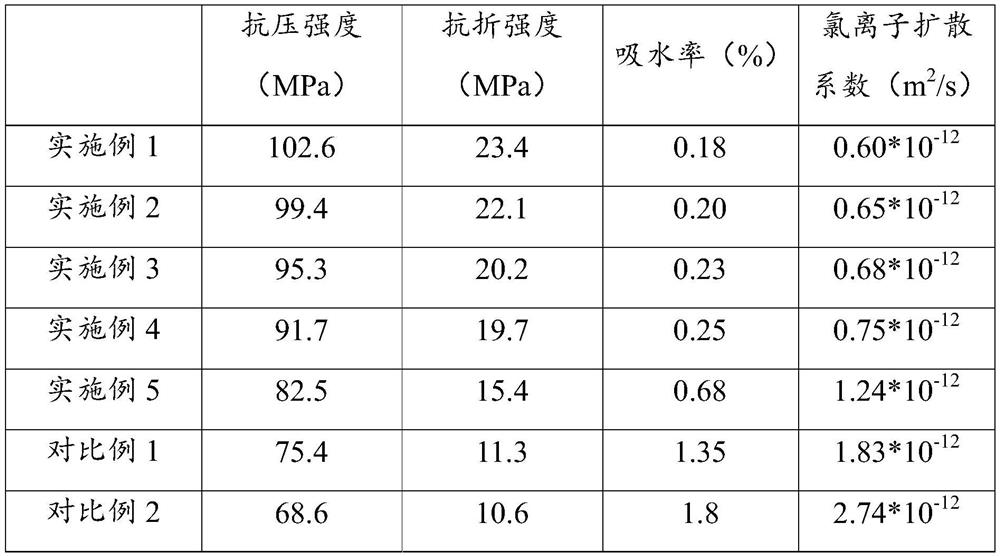

[0013] The high-speed rail-phase silicate cement clinker and water were mixed after mixing, and stirred into a wet material after mixing, then placed the wet material in the mold, and then placed in the blank again. Accelerated carbonization treatment was carried out in a carbonized maintenance chamber to obtain a high-speed rail-phase silicate cement product; wherein the mineral composition of the above high-speed rail-phase silicate cement clinker is: silicate 20-33%, α-silicate 2- 8%, γ-silicon silicate 36-41%, three calculations of aluminate acid, iron aluminate, 200-35%. Preferably, the mineral composition of the above-mentioned high-speed rails of the silicate cement clinker is: 3-25% of silicate, α-silicon silicate 3-6%, γ-silicate 38-41%, aluminate Three calcium 1-3%, ferro-aluminated acid quartet calcium 29-35%. More preferably...

Embodiment 1

[0025] This example provides a high-speed rail-phase silicate cement product which is obtained by the following steps:

[0026] (1) 90.13 limestones, 6.46 iron ore and 1.41 sandstones were broken, emitted, ingredient, and ore chemifiers (CAF) 2 After 2 copies of powder and homogenization, the preheater and the decomposition furnace transferred into the rotary kiln, quenched after calcination at 1250 ° C for 20 minutes, and the high-speed iron-phase silicate cement clinker is obtained.

[0027] (2) After mixing 87 parts of the high-speed rails of the silicate cement, mixed with 13 parts of the tap water, stir well, then placed the wet material in a constant shape of the mold, the blank is 400 × 400 × 20mm sheet, molding pressure 20MPa, molding time is 5 minutes; the blank is placed in a carbonized maintenance chamber for accelerated carbonization treatment, and the condition of carbonization is 20 ° C, and the relative humidity is 75%, the carbon dioxide concentration is 75%, and t...

Embodiment 2

[0029] This example provides a high-speed rail-phase silicate cement product which is obtained by the following steps:

[0030] (1) 92.11 limestones, 6.05 iron ore, 8.36 sandstones were combined, and the mineralization agent was added. 4 After 1 case, powder milling and homogenization, the preheater and the decomposition furnace transferred into the rotary kiln, and quenched after 20 minutes at 1280 ° C for 20 minutes, high-speed iron-phase silicate cement clinker;

[0031](2) 85 parts and 15 parts of the above-mentioned high-speed, and 15 parts of the above-mentioned high-speed, and the mixture was mixed and uniformly made of a wet material, and then the wet material was placed in a certain shape of the mold pressed blank, the green body was 400 × 400 × The 100mm sheet, the molding pressure is 70MPa, the molding time is 6 minutes; the blank is placed in a carbonized maintenance chamber for accelerated carbonization treatment, the condition of carbonization is 30 ° C, relative hum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com