Cement composition for grouting and grout material comprising the same

A technology of cement composition and bonding material, applied in the field of grouting material and cement composition for grouting, can solve the problems of residual unreacted material, early hydration reaction, reduced durability and the like, and achieve the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

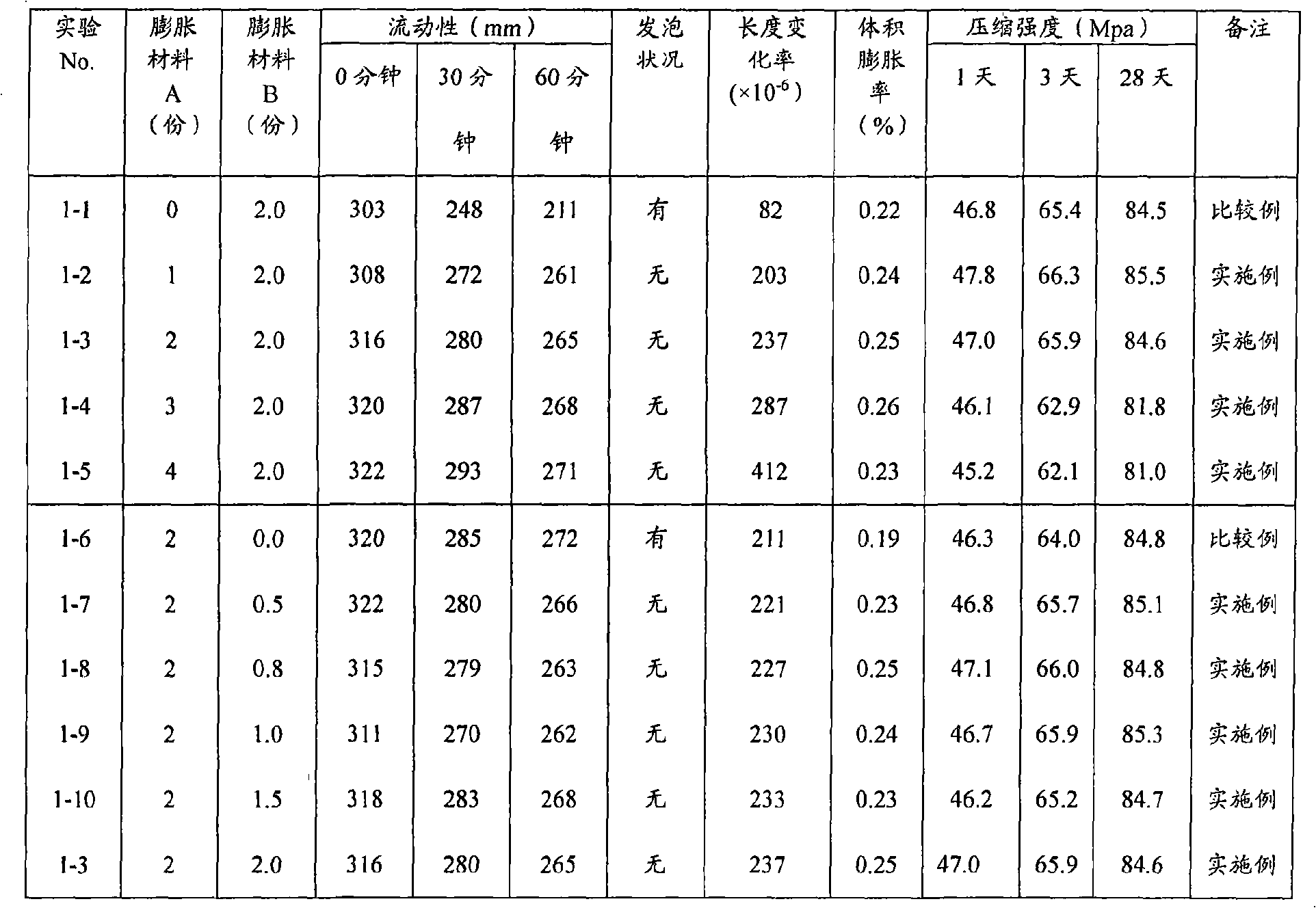

Embodiment 1

[0051] In 100 parts of bonding materials, the expansion material shown in Table 1, 6 parts of volcanic ash fine powder, 0.0014 parts of foaming agent, 1.3 parts of naphthalene sulfonate-based water-reducer and 0.2 part of melamine-sulfonate-based water-reducer and 100 parts Mix the fine aggregate, prepare the grouting material, add water to make the ratio of water / binding material 32%, stir and mix with a high-speed manual mixer, make grouting mortar, measure its fluidity, and evaluate the foaming state.

[0052] In addition, the prepared grouting mortar was poured in a sand box in a constant temperature and humidity room at 20°C and 80% RH, and the curing after one day was water curing at 20°C, and the length change rate, volume expansion rate and compressive strength were measured. . The results are also listed in Table 1.

[0053] Materials used

[0054] Cement: Quick-setting Portland cement, commercially available

[0055] Expansion material A:C 4 AF expansion material...

Embodiment 2

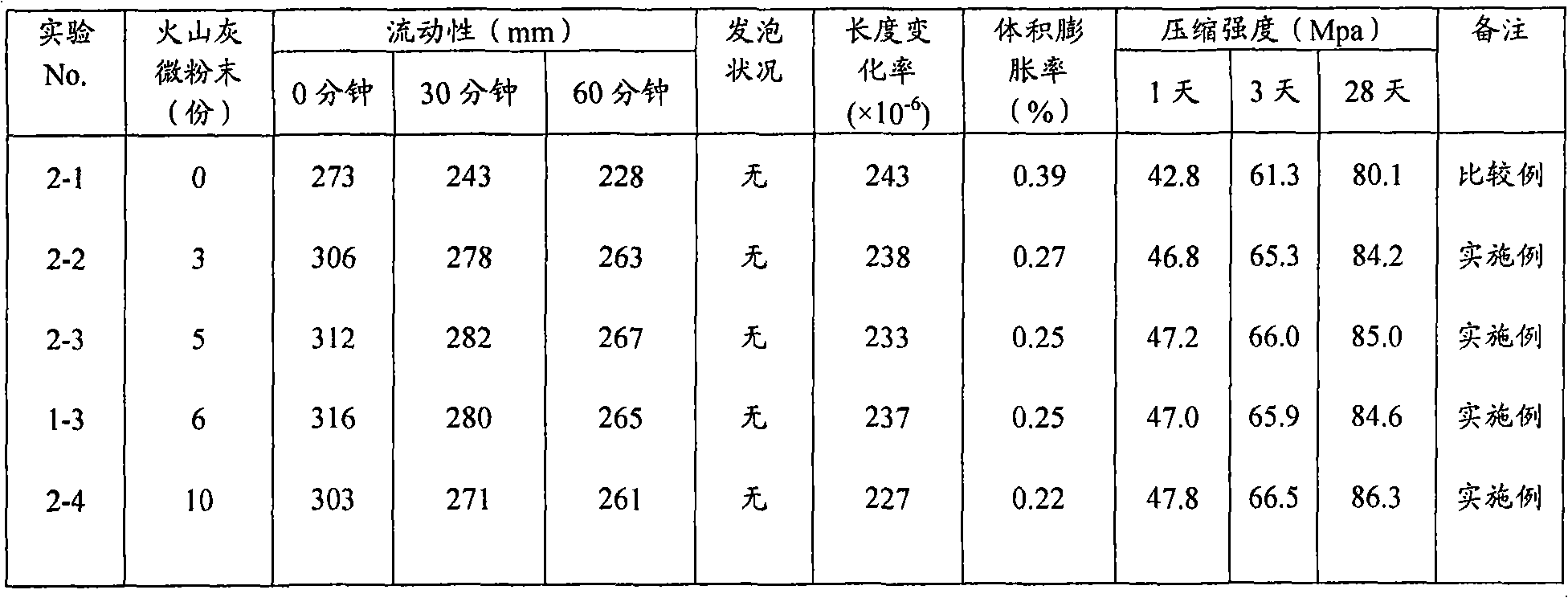

[0076] Mix 2 parts of expansion material A, 2 parts of expansion material B, pozzolan fine powder shown in Table 2, 0.0014 parts of foaming agent, 1.3 parts of water reducing agent a and 0.2 parts of water reducing agent b and 100 parts of bonding material in 100 parts of bonding material It carried out similarly to Example 1 except having prepared the grouting material as a fine aggregate. The results are also listed in Table 2.

[0077] Table 2

[0078]

[0079] As can be seen from Table 2, the grouting mortar of the embodiment of No.2-2~2-4 and No.1-3 containing 3~10 parts of pozzolan fine powder in 100 parts of bonding material has obtained excellent flow No air bubbles are produced, the length change rate and volume expansion rate are kept moderate, and the compressive strength is high.

[0080] On the other hand, the grouting mortar of the comparative example of Experiment No. 2-1 which did not contain fine pozzolan powder had low fluidity, a large volume expansion ...

Embodiment 3

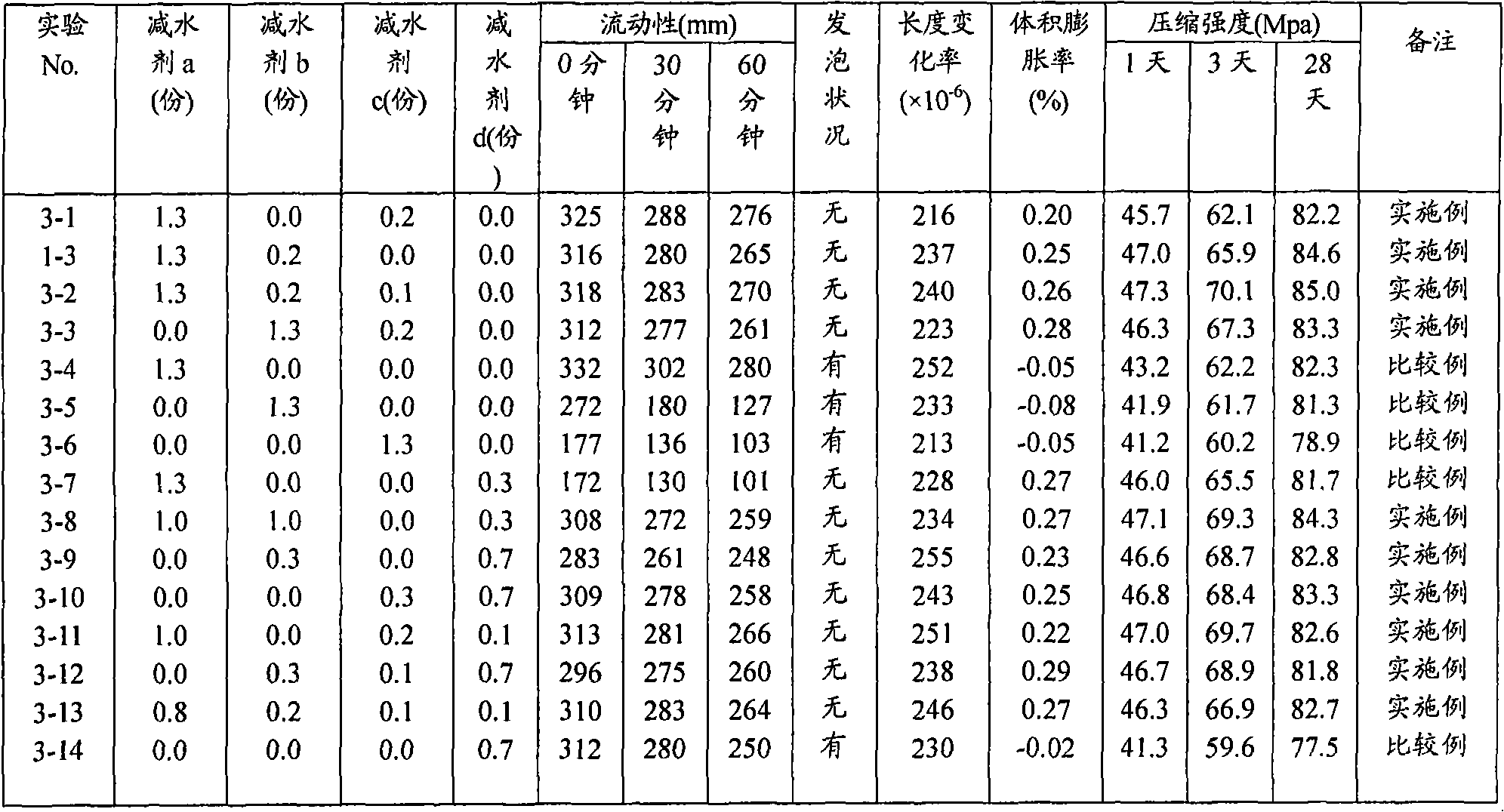

[0083] Mix 2 parts of expansion material A, 2 parts of expansion material B, 6 parts of pozzolan fine powder, 0.0014 parts of foaming agent, water reducing agent shown in Table 3 and 100 parts of fine aggregate in 100 parts of bonding material to prepare the grouting material , except that, it was carried out in the same manner as in Example 1. The results are also listed in Table 3.

[0084] Materials used

[0085] Water reducer c: Lignosulfonate-based water reducer, commercially available

[0086] Water reducer d: polycarboxylate water reducer, market product

[0087] table 3

[0088]

[0089] It can be known from Table 3 that the water reducer a (naphthalene sulfonate water reducer), water reducer b (melamine sulfonate water reducer), water reducer c (lignosulfonate Water-reducing agent), water-reducing agent d (polycarboxylate-based water-reducer) in combination And the grouting mortar of the embodiment that contains experiment No.3-1~3-3, No.1-3, No.3-8~3-13 has o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com