Vibration welding method for foamed aluminium scraper

A technology of vibration welding and aluminum foam, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of hindering the spread and wetting of solder, high melting point, and the inability of solder to spread, so as to improve the comprehensive mechanical properties, The effect of reducing overall weight and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

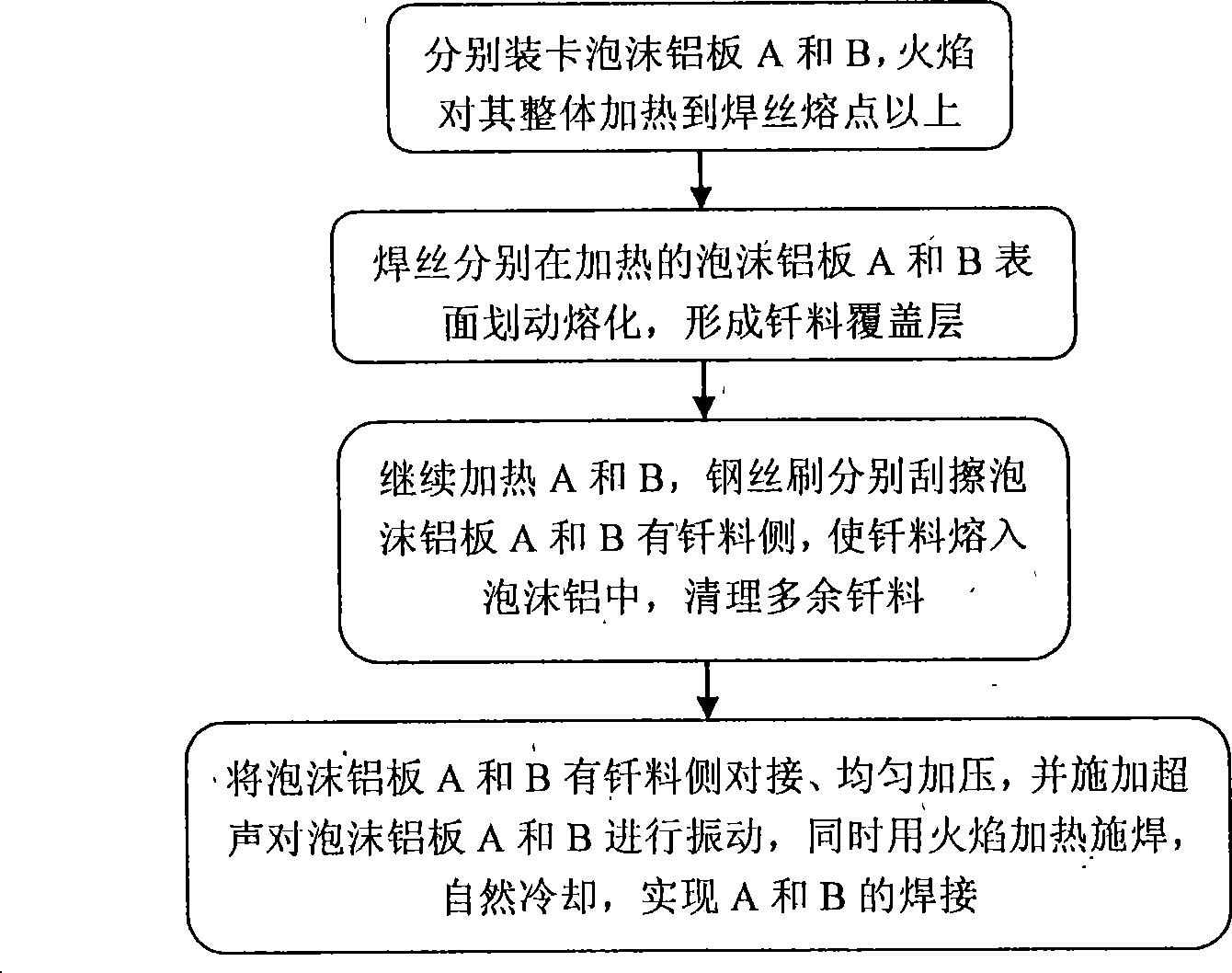

[0021] Embodiment 1, combining figure 2 , image 3 , Figure 4 , the implementation steps of a kind of aluminum foam scraping vibration welding method of the present invention are as follows:

[0022] Step 1: Fix the aluminum foam board A on the jig, and heat the whole foam aluminum board with flame or furnace temperature, so that the temperature of the foam aluminum board reaches 390°C.

[0023] Step 2: Swipe the welding wire to spread the molten metal evenly on the surface of foamed aluminum plate A.

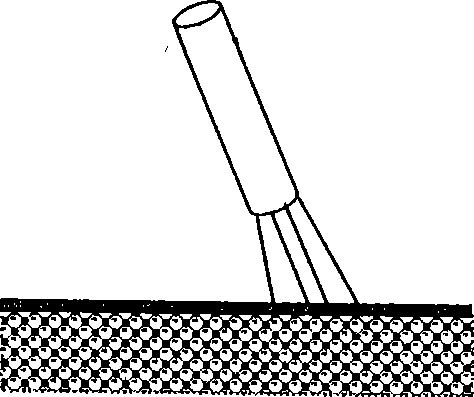

[0024] Step 3: Continue heating, and use a wire brush or steel wire to scrape the side of the aluminum foam plate A with brazing material, so that the brazing material gradually melts into the aluminum foam plate A to form a layer of solder adsorption layer.

[0025] Step 4: Clean up the excess solder, and use the same method to treat another piece of foamed aluminum plate B.

[0026] Step 5: Put the two processed aluminum foam boards A and B with solder side facing each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com