Tungsten-plated diamond particle, tungsten plating method, application of tungsten-plated diamond particle used as copper-based reinforced phase, and obtained diamond/copper composite material

A diamond particle and reinforcing phase technology, applied in metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problems of high interface thermal resistance, poor bonding between diamond particles and matrix, and reduce the interface heat. resistance, good surface bonding, and the effect of increasing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

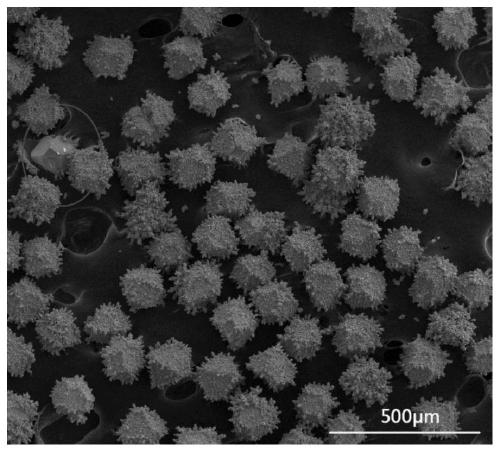

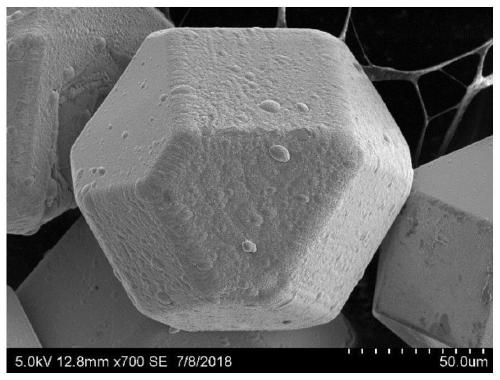

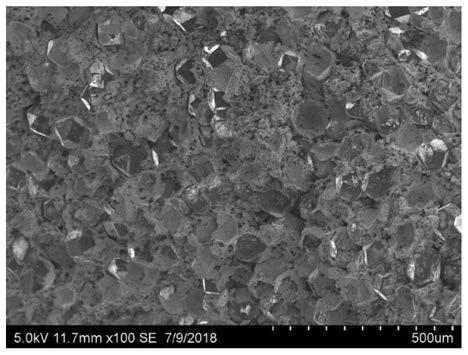

[0039] Weigh 2 g of synthetic diamond powder (100-150 μm in particle size), first put the diamond particles into an acetone solution, and clean them with ultrasonic vibration for 0.5 h to remove hydrocarbons, then wash them with deionized water until neutral; then Place the diamond particles in a 10g / L NaOH solution, clean them with ultrasonic vibration for 0.5h, clean and remove oil, take them out and wash them with deionized water until neutral; then place the diamond particles in 10% HNO 3 In the process, ultrasonic vibration was used to clean for 0.5h, and the cleaning was roughened. After taking it out, it was washed with deionized water until it was neutral; finally, the diamond particles were placed in an oven to dry. Continuous magnetron sputtering coating equipment is used to evenly spread the cleaned and dried diamond particles on the heating platform and then put the platform on the conveyor belt. During the deposition process, the platform is kept vibrating, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com