Pulse laser processing-based novel positive rake diamond abrasive tool manufacturing method

A technology of pulse laser and manufacturing method, which is applied in the direction of manufacturing tools, metal processing equipment, grinding devices, etc., to achieve the effect of improving surface integrity and improving the quality of processed surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] This embodiment is a method for manufacturing a positive rake angle brazed diamond grinding wheel by picosecond laser processing, which is realized according to the following steps:

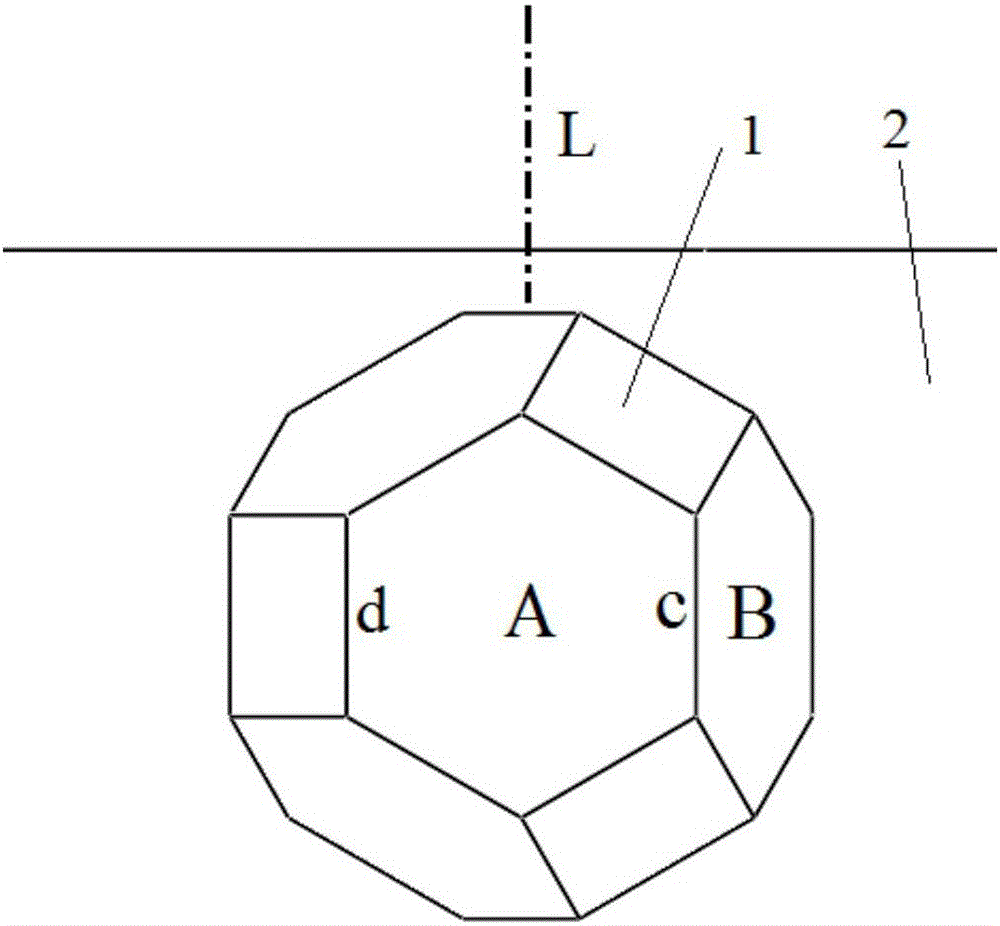

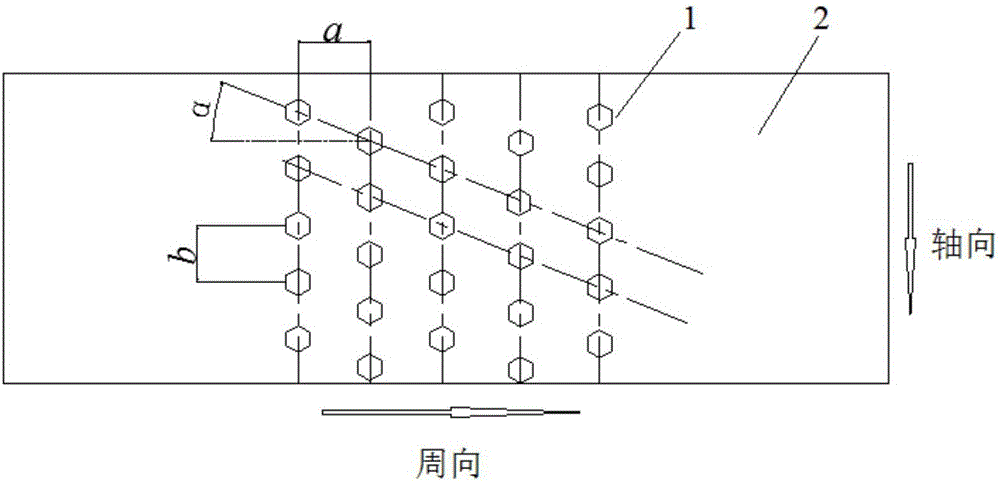

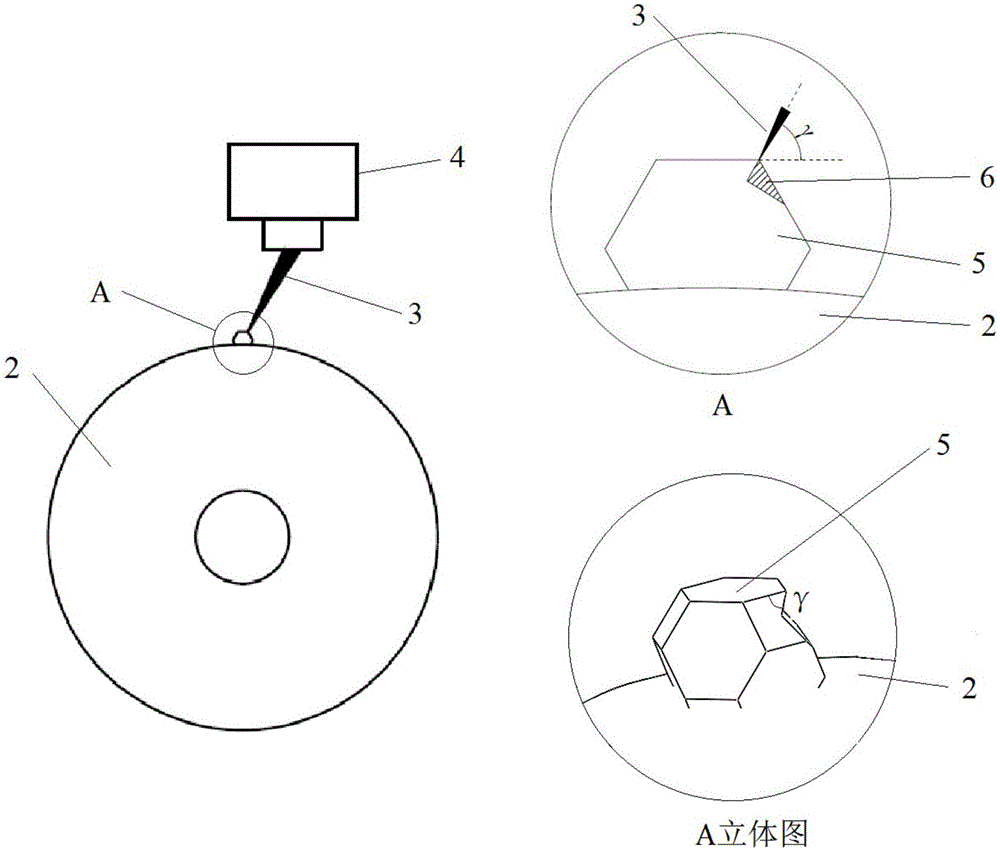

[0026] Step 1: Brazing is used to manufacture a diamond grinding wheel in which the abrasive grains are arranged in an orderly manner, and the mesh number of the grinding wheel is 25#. As we all know, common diamond abrasive crystals include octahedron, rhombic dodecahedron and truncated octahedron, etc. In this technical solution, the diamond abrasive grains of truncated octahedron are selected. During the manufacturing process of the grinding wheel, ensure that the top surface A of the diamond abrasive grain is parallel to the cut surface of the grinding wheel where the abrasive grain is located, and the intersection line c between the top surface A of the diamond abrasive grain and the right side B of the diamond abrasive grain, and the top surface A of the diamond abrasive grain The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com