Abrasion-resistance high-speed steel composite roller and preparation method thereof

A composite roll and high-speed steel technology, applied in the field of rolls, can solve problems such as easy cracking of rolls, poor uniformity of roll surface hardness, and decreased hardness of the working layer of the roll body, so as to improve strength and toughness, excellent wear resistance, promote refinement and The effect of homogenizing the distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

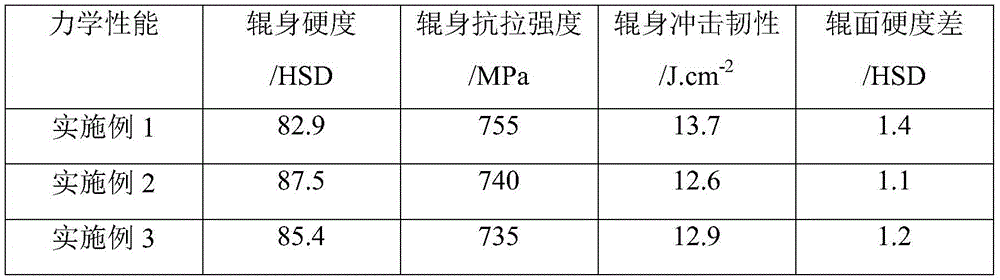

Embodiment 1

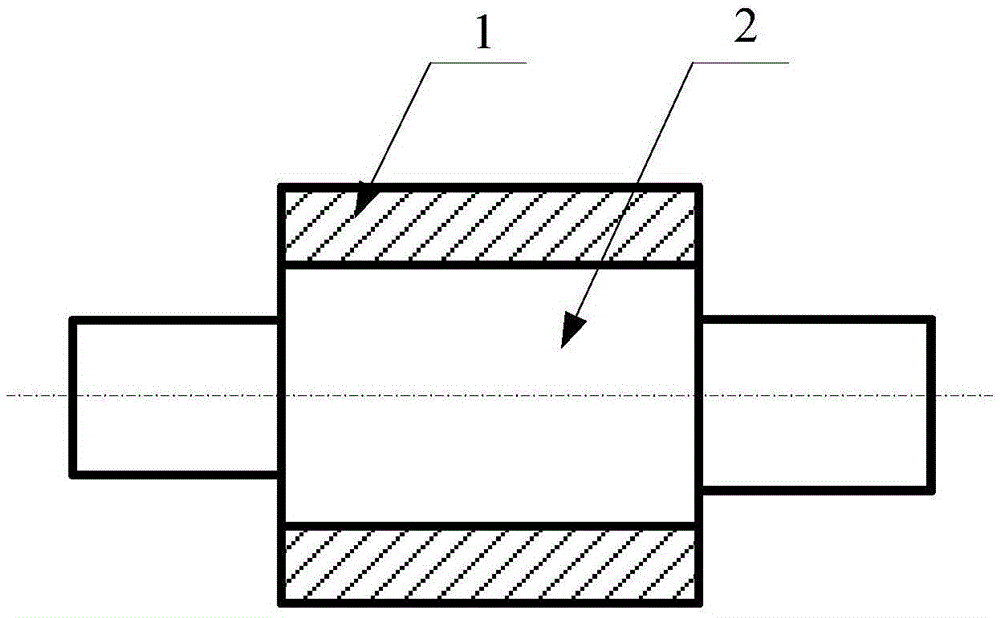

[0025] A wear-resistant high-speed steel composite roll and a preparation method thereof. The roll body 1 high-speed steel and the roll core 2 ductile iron are integrated by centrifugal composite casting. The specific preparation process steps are:

[0026] ① Melt the high-speed steel composite roll in a 750 kg intermediate frequency induction furnace. %V, 3.44%W, 1.19%Nb, 0.55%Ni, 0.47%Si, 0.75%Mn, 0.028%S, 0.031%P, balance Fe;

[0027] ②When the temperature of the molten steel in roll body 1 in step ① reaches 1621°C, the molten steel is taken out of the furnace and placed in a ladle, and the bottom of the ladle is pre-added with a multi-element aluminum-iron alloy deoxidizer. The chemical composition mass fraction of the multi-element aluminum-iron alloy deoxidizer is: 40.50% Al, 0.21% C , 2.99% Si, 2.52% Mn, 4.07% Ca, 2.94% Ba, 0.008% S, 0.016% P, the balance Fe, the amount of multi-element aluminum-iron alloy deoxidizer accounted for 0.35% of the mass fraction of molten st...

Embodiment 2

[0031] A wear-resistant high-speed steel composite roll and a preparation method thereof. The roll body 1 high-speed steel and the roll core 2 ductile iron are integrated by centrifugal composite casting. The specific preparation process steps are:

[0032] ① Melt the high-speed steel composite roll body 1 in a 500-kg medium-frequency induction furnace, which refers to the working part of the roll. The chemical composition and mass fraction of the molten steel of the roll body 1 are controlled at 2.36%C, 3.51%Cr, 5.85%Mo, 5.96% %V, 1.57%W, 0.67%Nb, 1.19%Ni, 0.78%Si, 0.31%Mn, 0.024%S, 0.028%P, balance Fe;

[0033] ②When the temperature of the molten steel on roll body 1 in step ① reaches 1647°C, the molten steel is taken out of the furnace and placed in a ladle, and the bottom of the ladle is pre-added with a multi-element aluminum-iron alloy deoxidizer. The chemical composition mass fraction of the multi-element aluminum-iron alloy deoxidizer is: 43.89% Al, 0.20% C , 2.07% Si,...

Embodiment 3

[0037] A wear-resistant high-speed steel composite roll and a preparation method thereof. The roll body 1 high-speed steel and the roll core 2 ductile iron are integrated by centrifugal composite casting. The specific preparation process steps are:

[0038] ① First melt the high-speed steel composite roll in a 1000 kg medium-frequency induction furnace. %V, 2.60%W, 0.84%Nb, 0.79%Ni, 0.66%Si, 0.42%Mn, 0.014%S, 0.026%P, balance Fe;

[0039] ②When the temperature of the molten steel on roll body 1 in step ① reaches 1639°C, the molten steel is taken out of the furnace and placed in a ladle. The bottom of the ladle is pre-added with a multi-element aluminum-iron alloy deoxidizer. The chemical composition mass fraction of the multi-element aluminum-iron alloy deoxidizer is: 42.37% Al, 0.31% C , 2.58% Si, 2.91% Mn, 4.35% Ca, 2.88% Ba, 0.011% S, 0.018% P, the balance Fe, the amount of multi-element aluminum-iron alloy deoxidizer accounted for 0.45% of the mass fraction of molten steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com