Mould having bionic non smooth surface

A non-smooth surface and mold technology, applied in the field of molds with bionic non-smooth surfaces, to achieve the effects of improving wear resistance, reducing bonding force, and improving thermal fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

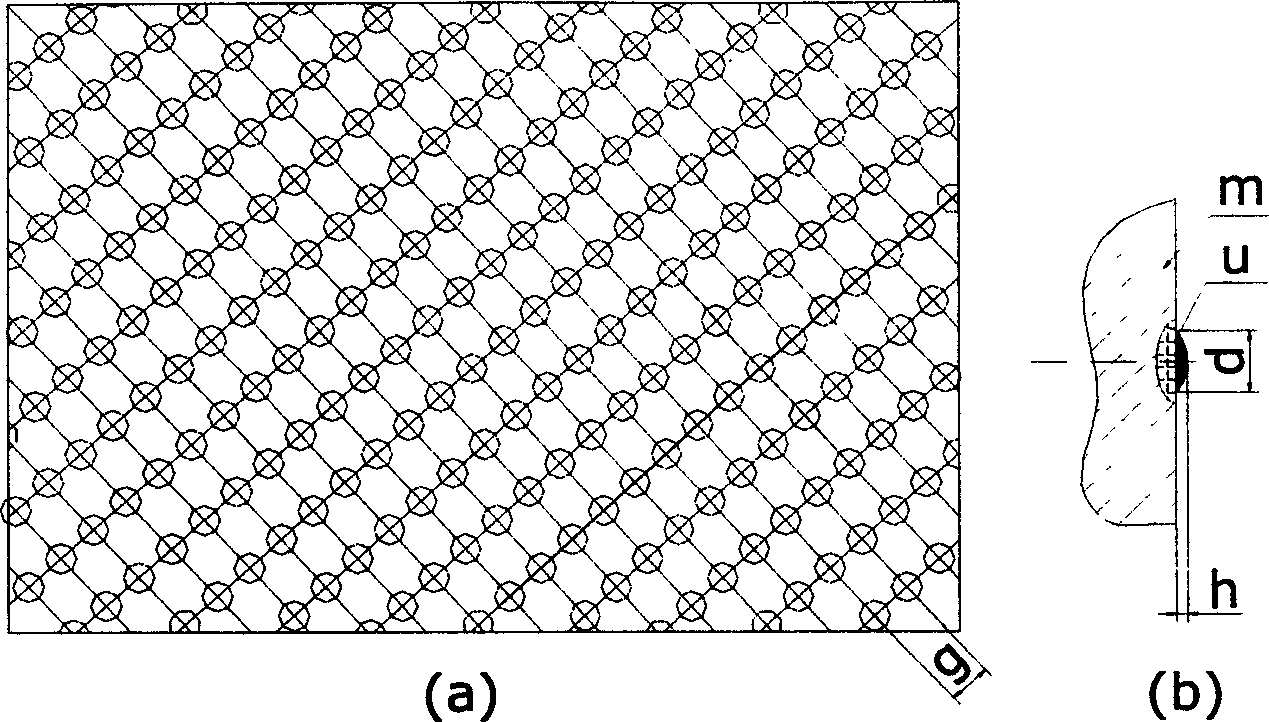

[0046] Manufacture of die-casting molds for auto parts covers with spherical crown convex hull non-smooth shape on the surface.

[0047] refer to figure 1 , the non-smooth working surface of the mold is distributed with spherical crown convex hull units u in regular lattice on the surface of the base m, the diameter d of the spherical crown bottom circle is 0.02mm, and the height h of the spherical crown is 0.01mm. The distance g between spherical crown units is 0.03mm, and the mold material is H11 mold steel. Under the condition of die-casting AlSi9Cu3 aluminum alloy, the service life of the mold with bionic non-smooth surface is 1.7 times longer than that of the smooth surface mold with the same base material. The cost of processing biomimetic non-smooth surfaces is only 17% higher.

Embodiment 2

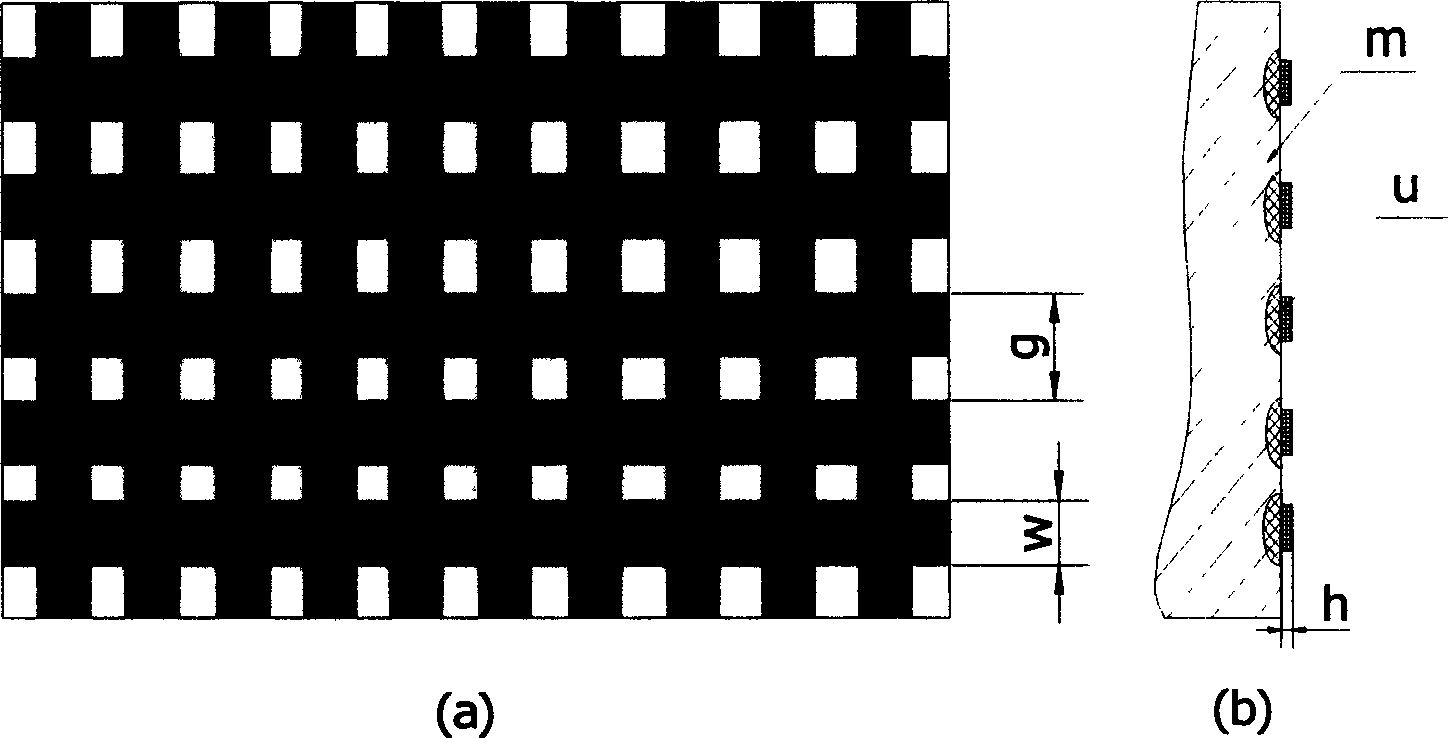

[0049] Fabrication of die-casting molds for automotive parts covers with raised mesh non-smooth morphology on the surface.

[0050] refer to figure 2 , the non-smooth working surface of the mold is distributed with raised stripe units u in grid form on the surface of the substrate m, the stripe width w is 0.02mm, the stripe height h is 0.05mm, and the stripe unit spacing g is 0.03mm, the mold material is H11 mold steel, under the condition of die-casting AlSi9Cu3 aluminum alloy, the service life of the mold with bionic non-smooth surface is 1.8 times higher than that of the smooth surface mold of the same base material, and the cost of processing bionic non-smooth surface is increased by 17% .

Embodiment 3

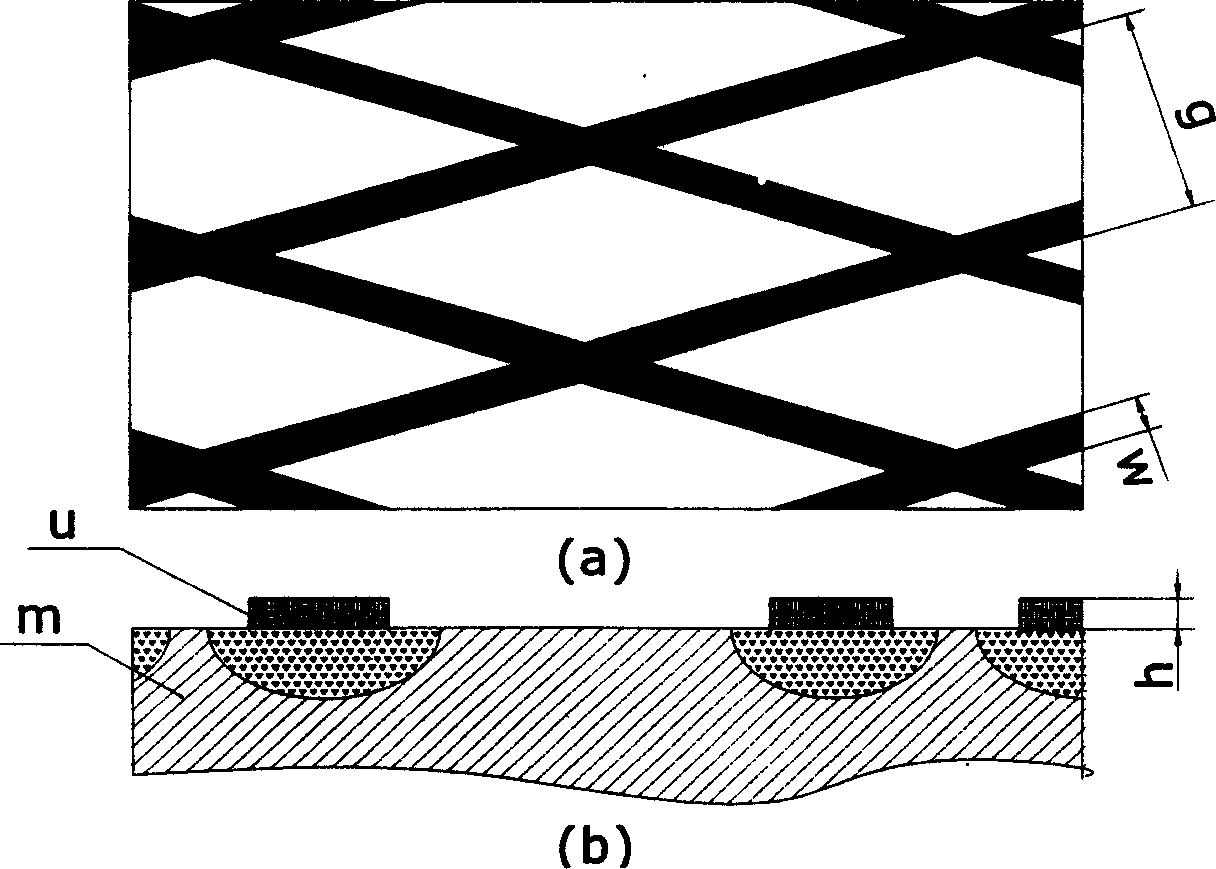

[0052] Fabrication of die-casting molds for automotive parts covers with raised mesh non-smooth morphology on the surface.

[0053] refer to image 3 , the non-smooth working surface of the mold is distributed with raised stripe units u in grid form on the surface of the substrate m, the stripe width w is 0.1mm, the stripe height h is 0.2mm, and the stripe unit spacing g is 0.8mm, the mold material is H11 mold steel, under the condition of die-casting AlSi9Cu3 aluminum alloy, the service life of the mold with bionic non-smooth surface is 1.5 times higher than that of the smooth surface mold of the same base material, and the cost of processing bionic non-smooth surface is increased by 15% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Concave depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com