Halogen-free flame-retardant master batch for continuous long glass fiber reinforced polypropylene and preparation method of halogen-free flame-retardant master batch

A technology of flame retardant masterbatch and polypropylene, which is applied in the field of flame retardant modification of engineering plastics, and can solve the problems that related technologies have not been reported publicly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing a halogen-free flame-retardant masterbatch for continuous long glass fiber reinforced polypropylene, which comprises the following steps:

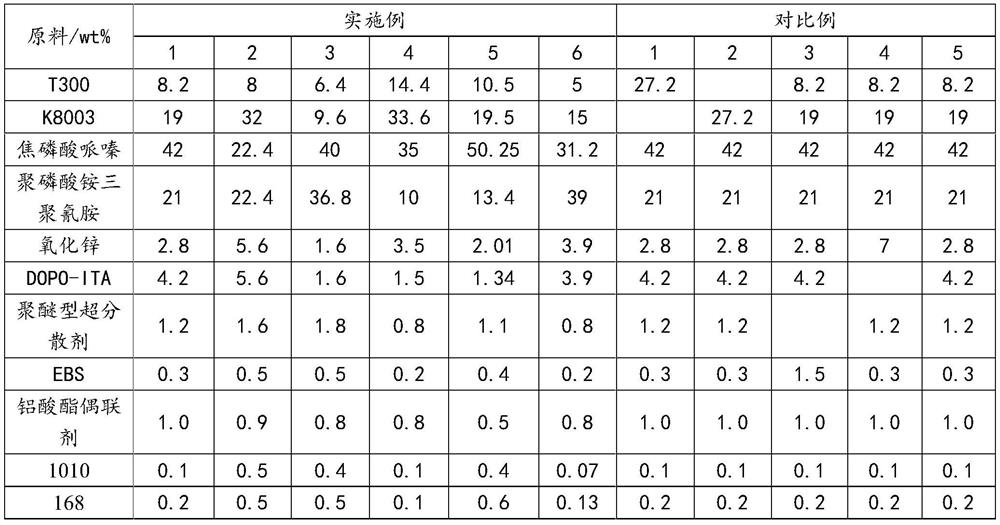

[0031] STEP101: Provide raw materials for preparing the halogen-free flame-retardant masterbatch for continuous long glass fiber reinforced polypropylene, the raw material for the continuous long glass fiber reinforced polypropylene is made of polypropylene carrier, halogen-free flame-retardant agent, hyperdispersant, lubricant, coupling agent, and antioxidant;

[0032] STEP102: Feed the raw material components in the halogen-free flame retardant into a high-speed mixer according to the corresponding mass percentage, pre-mix for 5 minutes to 10 minutes, and discharge to obtain a uniformly mixed halogen-free flame retardant;

[0033] STEP103: Feed the polypropylene carrier, the hyperdispersant, the lubricant, the coupling agent and the antioxidant raw materials into a high-sp...

Embodiment 1

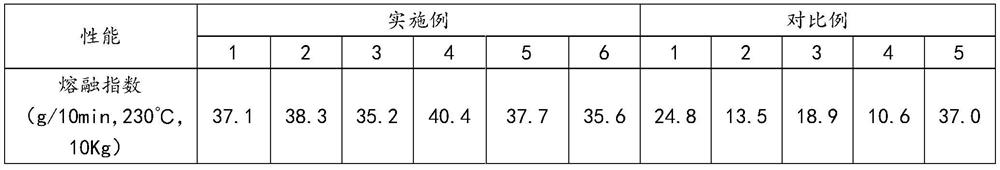

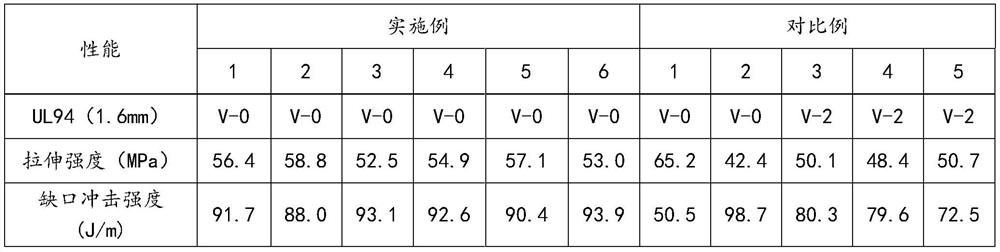

[0060] In embodiment 1, homopolypropylene and copolypropylene are mixed and used as the resin carrier of the masterbatch, and the melt index of the flame retardant masterbatch is higher than that of homopolypropylene used alone in contrast 1 and copolypropylene used alone in comparative example 2 as The masterbatch of the carrier shows that the mixed use of polypropylene carrier can improve the processing fluidity of the masterbatch. In addition, when the flame-retardant masterbatch prepared by using homopolypropylene alone as the carrier in Comparative Example 1 is applied to the continuous long glass fiber reinforced polypropylene material, the impact performance of the flame-retardant continuous long glass fiber reinforced polypropylene material is significantly reduced, and a slight float appears. fiber. Comparative Example 2 When the flame retardant masterbatch prepared by using copolymerized polypropylene alone as a carrier is applied to continuous long glass fiber reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com