Water-lubricated bearing material and preparation method thereof

A water-lubricated bearing and lubricant technology, applied in the field of water-lubricated bearing materials and their preparation, can solve the problems of abnormal noise and vibration, inability to guarantee the safety of ships, poor flexibility and elasticity, etc., and increase the amount of compression deformation. , Increase the effect of shock absorption and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

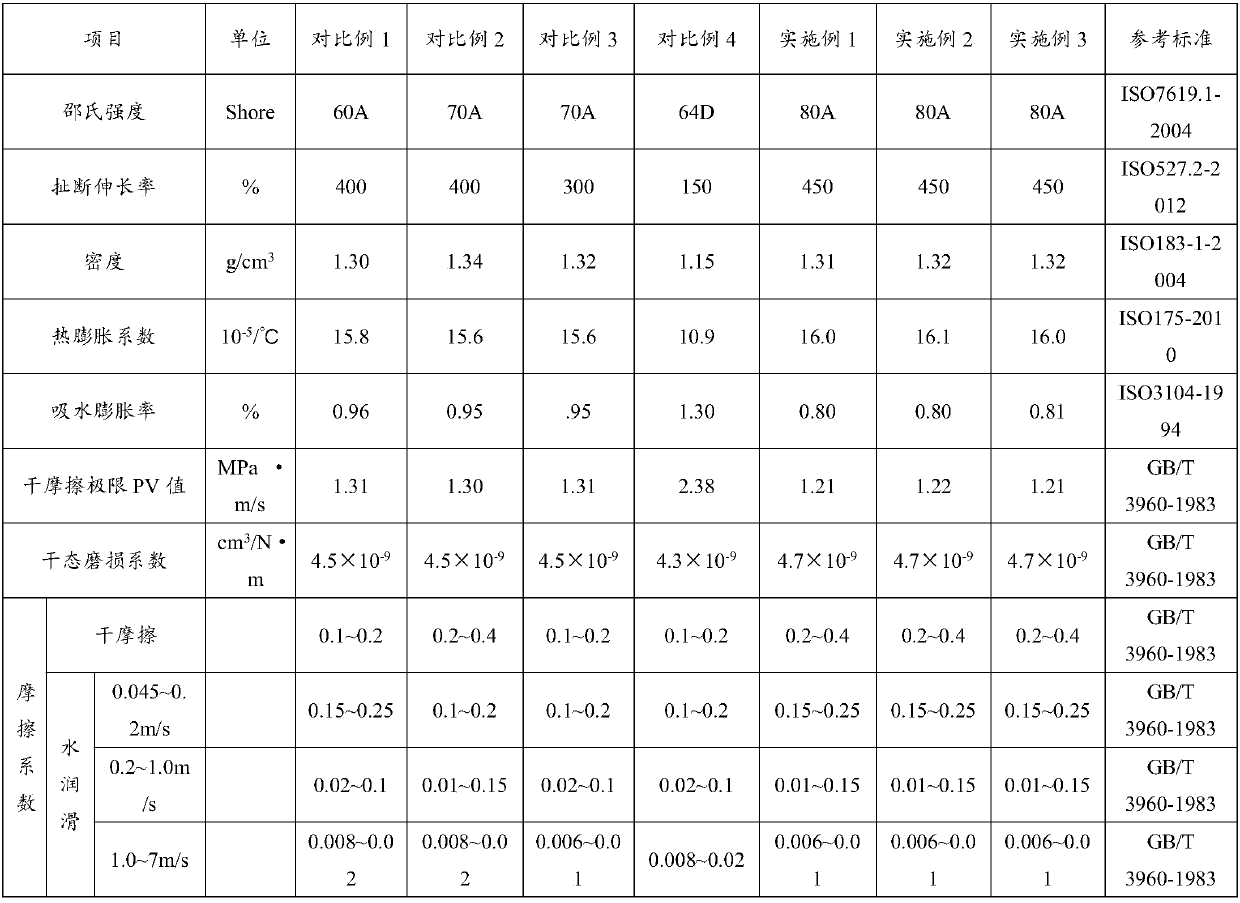

Embodiment 1

[0039] Embodiment 1 Preparation of water-lubricated bearing material

[0040] (1) According to parts by weight, mix 20 parts of phenolic resin, 40 parts of nitrile rubber, 1 part of graphene powder and 20 parts of basalt fiber, 30KHz ultrasonic, 10min, wait until the previous material 1;

[0041] (2) Add 0.1 part of vulcanizing agent, 5 parts of softener and 10 parts of lubricant into the previous material 1, and knead evenly to obtain the previous material 2;

[0042] (3) The pre-material 2 was placed in a mold for vulcanization, the vulcanization temperature was 150° C., the vulcanization pressure was 30 MPa, and the vulcanization time was 90 minutes to obtain a water-lubricated bearing material.

Embodiment 2

[0043] Embodiment 2 Preparation of water-lubricated bearing material

[0044] (1) According to parts by weight, mix 25 parts of phenolic resin, 45 parts of nitrile rubber, 5 parts of graphene powder and 25 parts of basalt fiber, 40KHz ultrasonic, 10min, wait until the former material 1;

[0045] (2) Add 0.5 parts of vulcanizing agent, 8 parts of softening agent, and 15 parts of lubricant into pre-material 1, and knead evenly to obtain pre-material 2;

[0046] (3) The pre-material 2 was placed in a mold for vulcanization, the vulcanization temperature was 160° C., the vulcanization pressure was 40 MPa, and the vulcanization time was 60 minutes to obtain a water-lubricated bearing material.

Embodiment 3

[0047] Embodiment 3 Preparation of water-lubricated bearing material

[0048] (1) According to parts by weight, mix 30 parts of phenolic resin, 50 parts of nitrile rubber, 10 parts of graphene powder and 30 parts of basalt fiber, 50KHz ultrasonic, 10min, wait until the former material 1;

[0049] (2) Add 1 part of vulcanizing agent, 10 parts of softening agent and 20 parts of lubricant into pre-material 1, and knead evenly to obtain pre-material 2;

[0050] (3) The pre-material 2 was placed in a mold for vulcanization, the vulcanization temperature was 180° C., the vulcanization pressure was 50 MPa, and the vulcanization time was 30 minutes to obtain a water-lubricated bearing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com