High freezing resistance water permeable concrete additive and preparation method thereof

A permeable concrete and admixture technology, applied in the field of concrete admixtures, can solve problems such as sudden reduction in service life, improve anti-fouling ability, reduce maintenance frequency and difficulty, and improve frost resistance

Pending Publication Date: 2018-05-01

长春市城建维护集团股份有限公司

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The use of ordinary permeable concrete in the severe cold areas of the north has caused its service life to decrease sharply due to the problem of frost heave

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

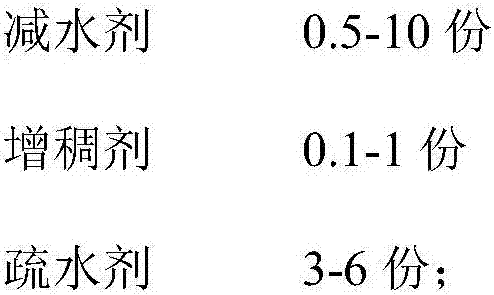

[0029] A high antifreeze permeable concrete admixture, each component is composed of the following parts by weight:

[0030]

Embodiment 2

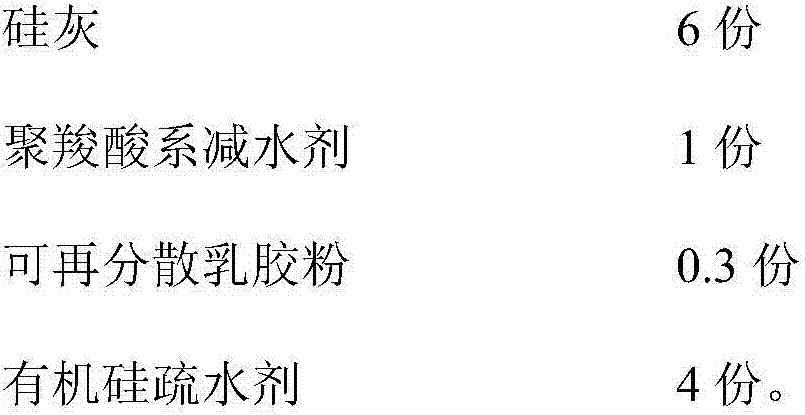

[0032] A high antifreeze permeable concrete admixture, each component is composed of the following parts by weight:

[0033]

Embodiment 3

[0035] A high antifreeze permeable concrete admixture, each component is composed of the following parts by weight:

[0036]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of concrete additives and relates to a high freezing resistance water permeable concrete additive and a preparation method thereof. The high freezing resistance water permeable concrete additive consists of the following components in parts by weight: 5-10 parts of mixing materials, 0.5-10 parts of a water reduction agent, 0.1-1 part of a thickening agent and 3-6 parts of a water repellent agent, wherein the mixing material is silicon ash or coal ash; and the granularity of the mixing material is 300-400 meshes. The preparation method comprises thefollowing steps: mixing the mixing material, the water reduction agent, the thickening agent and the water repellent agent according to the parts by weight, grinding, stirring the mixed material at amedium speed till the components are uniform, and discharging. The additive provided by the invention is capable of enriching fine capillary cavities and micro cracks in a cementing layer of water permeable concrete, improving the strength of a cement adhesive layer, and improving the strength of the water permeable concrete, so that the freezing resistance of the concrete is improved. In addition, due to adoption of the water repellant agent, a water repellant surface is formed on the surface of the cementing layer of concrete, so that water inside the concrete can be well discharged, and thefreezing resistance and the water permeability of the concrete are improved.

Description

technical field [0001] The invention belongs to the technical field of concrete admixtures, in particular relates to a concrete admixture and a preparation method thereof, in particular to a high antifreeze permeable concrete admixture and a preparation method thereof. Background technique [0002] Permeable concrete is an ecological and environmentally friendly concrete. It is a concrete with continuous pores made through material research and selection and a special process. It has a certain strength and a certain degree of air permeability. It can coexist harmoniously with the natural environment, and it is a pavement material for human beings to construct a comfortable living environment. [0003] With the development of urban construction, the sharp increase in hardened ground has led to a sharp decrease in urban sponges, destroying the ecological balance, and losing the functions of water storage and flood diversion. In recent years, with the advancement of the "spong...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B24/42C04B24/38C04B103/60

CPCC04B40/0039C04B2103/601C04B18/146C04B24/24C04B24/42C04B18/08C04B2103/302C04B24/383C04B2103/65C04B24/125

Inventor 李冠杰张立霞王可孙艳刚安署浩田伟

Owner 长春市城建维护集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com