Biomass coke-based bimetallic catalyst as well as preparation method and application thereof

A bimetallic catalyst, biomass coke technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as catalyst sintering and deactivation, achieve inhibition The effect of sintering, cracking promotion, and prolonging the active time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the above-mentioned biomass coke-based bimetallic catalyst, comprising the following steps:

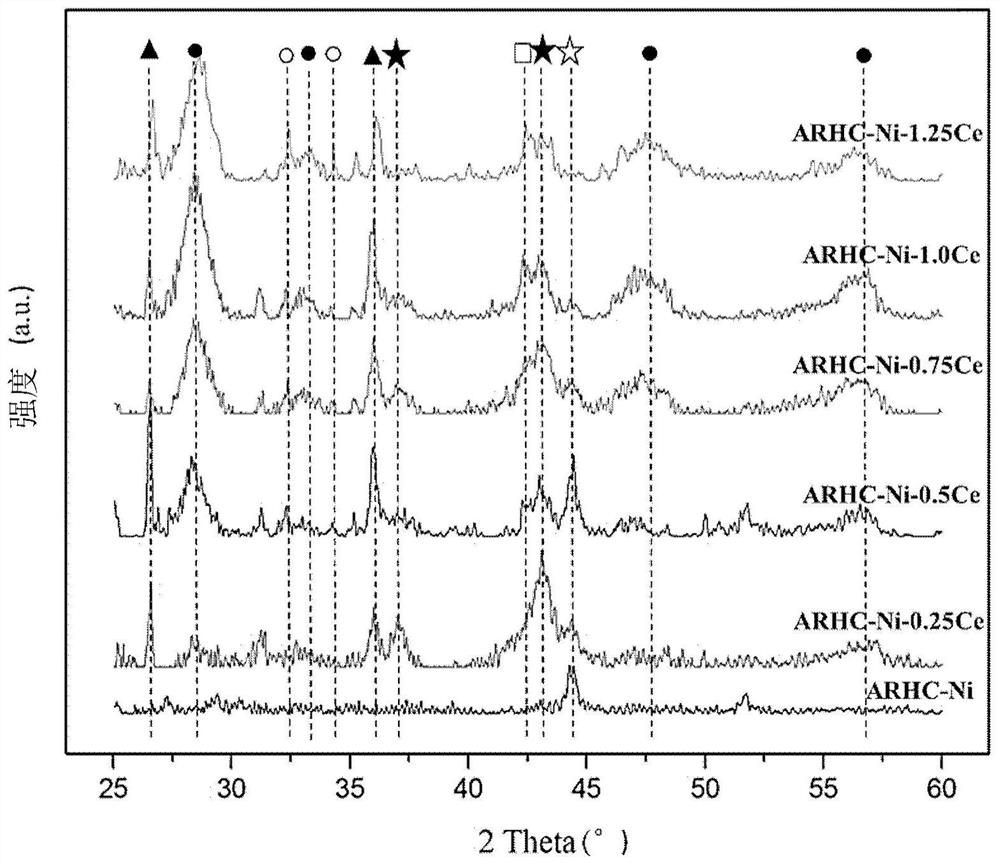

[0035] The metal salts of nickel and cerium were supported on screened biomass char by impregnation method and calcined under nitrogen atmosphere to form nickel-cerium intermetallic compounds.

[0036] As a preference, the biomass coke is obtained from rice husk as raw material, followed by pyrolysis gasification, microwave activation, crushing and screening; specifically, the condition of pyrolysis gasification is air gasification at 600-700°C; After microwave activation, the mass content of volatile matter in biomass coke is less than 7%, and the mass content of fixed carbon is higher than 45%. shape.

[0037] Wherein, the conditions for microwave activation are microwave heating under a nitrogen atmosphere, the microwave power is 500-600W, the heating temperature is 600-800°C, and the heating time is greater than or...

Embodiment 1

[0051] Embodiment 1: Preparation of biomass coke-based bimetallic catalyst

[0052] Preparation of biomass char carrier:

[0053] Directly obtained industrial-grade rice husk gasification residue obtained by air gasification at 700°C with coarse rice husk as raw material. According to the results of industrial analysis and elemental analysis, microwave activation was performed on it. The activation condition was: under nitrogen atmosphere Microwave heating, the microwave power is 600W, the heating temperature is 800°C, and the activation lasts for 1 hour. The mass content of the volatile matter of the obtained biomass char is 6.6%, and the fixed carbon content is 48.01%. Then finely crush the microwave-activated biomass coke so that the particle size is between 40 and 60 meshes, and select the rod-shaped or needle-shaped materials for future use.

[0054] Preparation of biomass coke-based bimetallic catalysts:

[0055] Weigh 15g of the above-mentioned biomass coke as a c...

Embodiment 2

[0056] Embodiment 2: Preparation of biomass coke-based bimetallic catalyst

[0057] Preparation of biomass char carrier:

[0058] The industrial-grade rice husk gasification residue obtained by air gasification of coarse rice husk at 500°C was directly obtained. According to the results of industrial analysis and elemental analysis, microwave activation was performed on it. The activation condition was: under nitrogen atmosphere Microwave heating, the microwave power is 500 W, the heating temperature is 550 ° C, and the activation lasts for 1 hour. The mass content of the volatile matter of the obtained biomass char is 6.9%, and the fixed carbon content is 47.2%. Then the microwave-activated biomass coke is finely crushed so that the particle size is between 40 and 60 meshes, and the rod-shaped or needle-shaped materials are selected for use.

[0059] Preparation of biomass coke-based bimetallic catalysts:

[0060] Take 15g of the above-mentioned biomass coke as a cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com