Cobalt modification silicoaluminophosphate molecular sieve and its preparation and catalytic application in MTO

A silicoaluminophosphate and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low conversion rate of raw materials, selectivity of low-carbon olefins and low life, and achieve selectivity High, good catalytic performance, the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

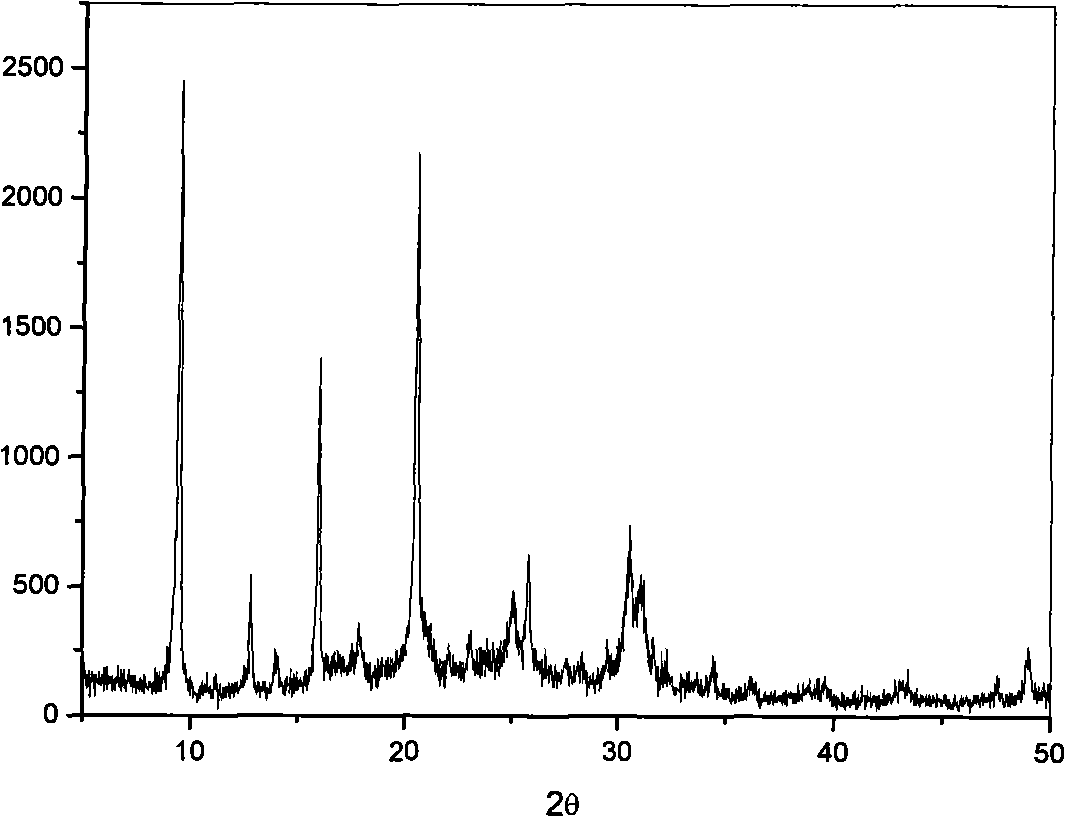

[0025] Synthesis of Co-SAPO-34 Molecular Sieve 1

[0026] According to the ratio: 3.0TEA: 0.75SiO 2 :Al 2 o 3 : 2.0H 3 PO 4 : 0.02Co(NO 3 ) 2 : 60H 2 O Weigh the raw material. Mix a certain amount of pseudo-boehmite and a certain amount of water thoroughly, then add H 3 PO 4 , Co(NO 3 ) 2 , silica sol, TEA (triethylamine), fully stirred for a certain period of time until uniform. The prepared gel was transferred into a 200ml crystallization kettle, sealed and crystallized at 190°C for 72 hours. The solid product was taken out, washed repeatedly with deionized water until it became neutral, and placed in a drying oven at 110° C. to dry overnight to obtain Co-SAPO-34 molecular sieve product 1.

Embodiment 2

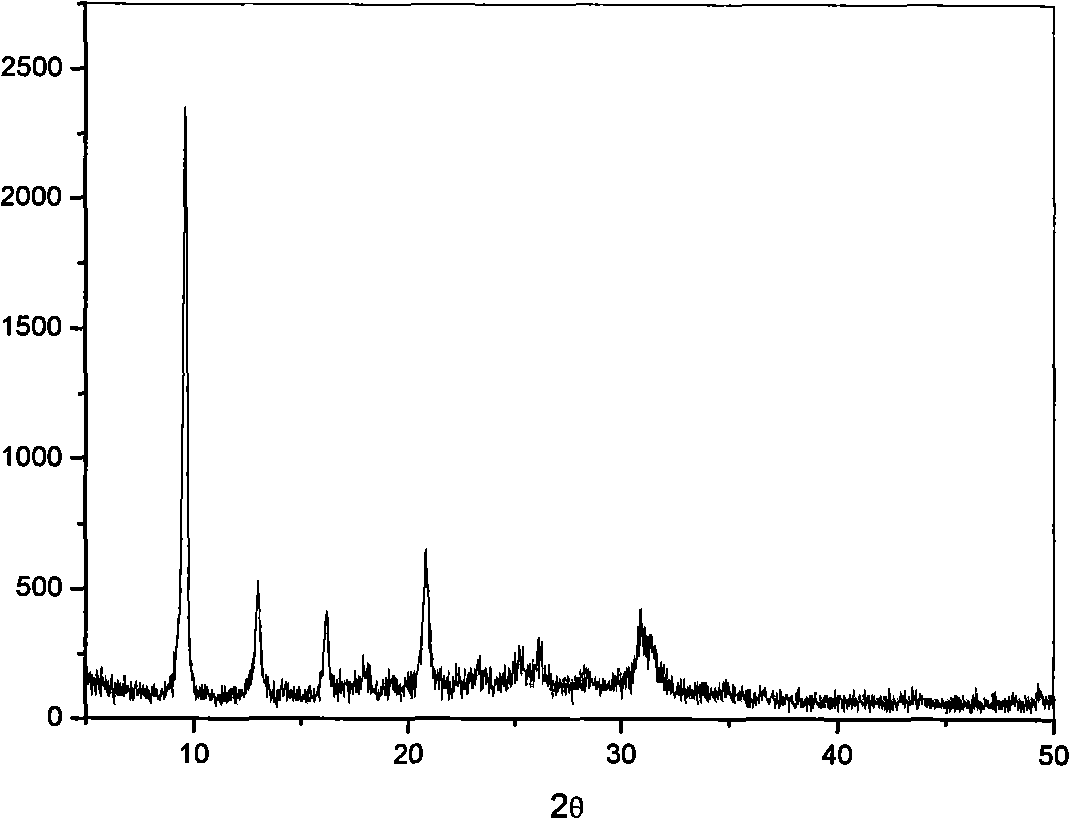

[0028] Synthesis of Co-SAPO-34 Molecular Sieve 2

[0029] According to the ratio: 3.0TEA: 0.75SiO 2 :Al 2 o 3 : 2.0H 3 PO 4 : 0.05Co(NO 3 ) 2 : 60H 2 O Weigh the raw material. Mix a certain amount of pseudo-boehmite and a certain amount of water thoroughly, then add H 3 PO 4 , Co(nO 3 ) 2 , silica sol, TEA, fully stirred for a certain period of time until uniform. The prepared gel was transferred into a 200ml crystallization kettle, sealed and crystallized at 190°C for 72 hours. The solid product was taken out, washed repeatedly with deionized water until it became neutral, and placed in a drying oven at 110° C. to dry overnight to obtain Co-SAPO-34 molecular sieve product 2.

Embodiment 3

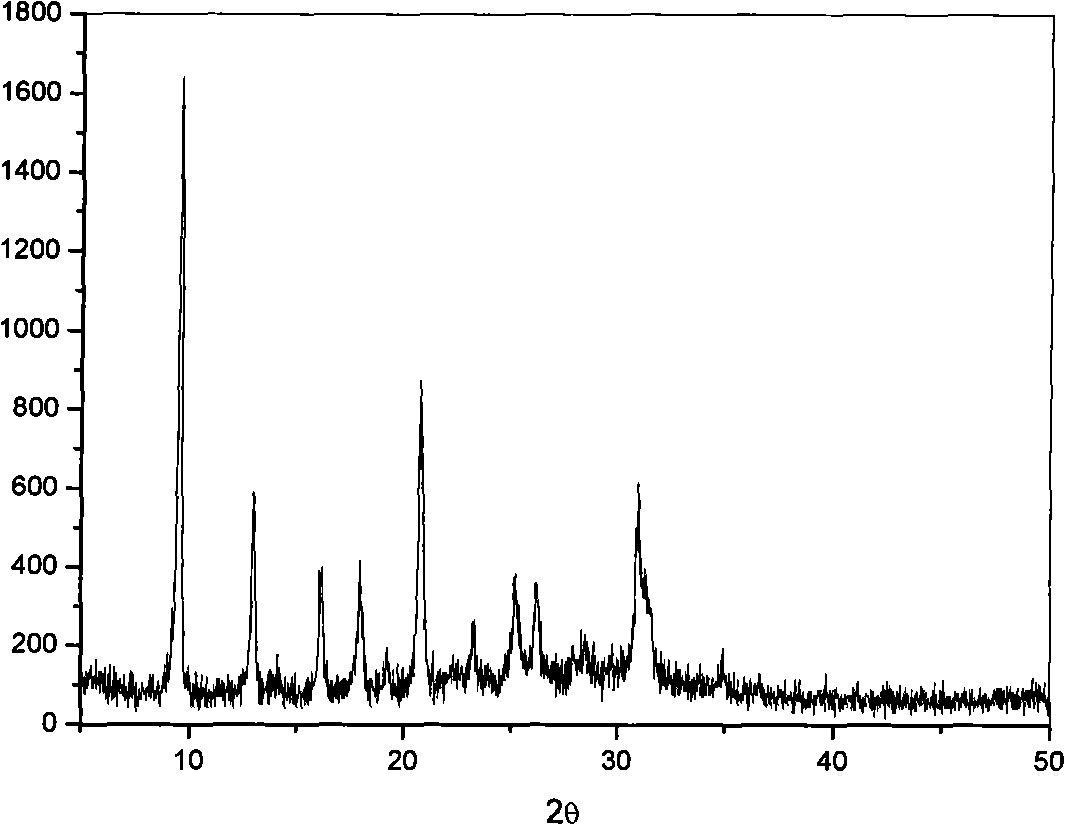

[0031] Synthesis of Co-SAPO-34 Molecular Sieve 3

[0032] According to the ratio: 3.0TEA: 0.75SiO 2 :Al 2 o 3 : 2.0H 3 PO 4 : 0.10Co(NO 3 ) 2 : 60H 2 O Weigh the raw material. Mix a certain amount of pseudo-boehmite and a certain amount of water thoroughly, then add H 3 PO 4 , Co(NO 3 ) 2 , silica sol, TEA, fully stirred for a certain period of time until uniform. The prepared gel was transferred into a 200ml crystallization kettle, sealed and crystallized at 190°C for 72 hours. The solid product was taken out, washed repeatedly with deionized water until it became neutral, and placed in a drying oven at 110° C. to dry overnight to obtain Co-SAPO-34 molecular sieve product 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com