Method for Comprehensive Recovery of Active Components in Enzymatic Amoxicillin Mother Liquor

A technology of amoxicillin mother and amoxicillin, which is applied in the field of comprehensive recovery of active ingredients in enzymatic amoxicillin mother liquor, which can solve the problem of low efficiency, complex components, and no involvement in the conversion or recovery of D-hydroxyphenylglycine methyl ester, etc. problem, to achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

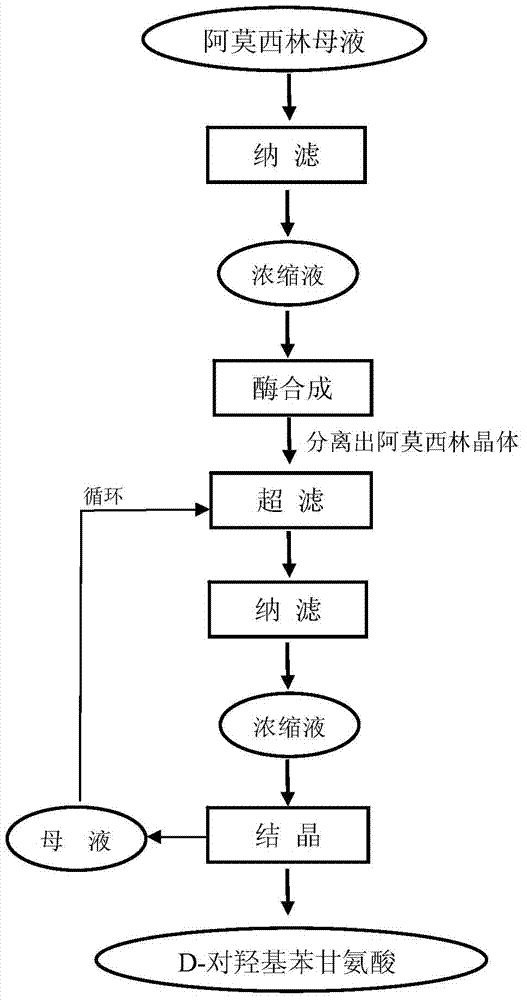

Image

Examples

Embodiment 1

[0034] According to the following steps, the active ingredients in the enzymatic amoxicillin mother liquor are comprehensively recovered:

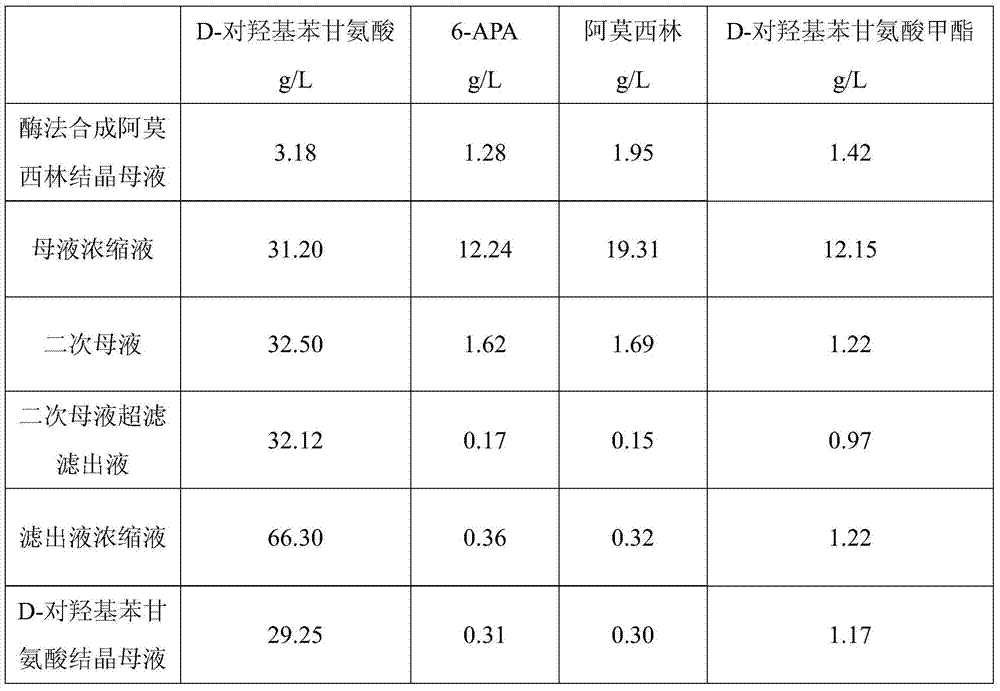

[0035] (1) Concentrated amoxicillin mother liquor

[0036] Take 1000L of the mother liquor of amoxicillin synthesized by enzymatic method after the crystallization and separation of amoxicillin, and detect the content of each component in the mother liquor by high performance liquid chromatography, and the detection results are shown in Table 1 below. Mother liquor pH is adjusted to 9.0 with 40wt% sodium hydroxide solution, makes the solubility of various substances in the mother liquor all relatively high, has guaranteed that there will not be crystallization in the nanofiltration concentration process; Dunn's nanofiltration membrane concentrates the amoxicillin mother liquor to 100L by nanofiltration at 5-8°C. During this process, only part of the inorganic salt and a small amount of D-hydroxyphenylglycine pass through the membrane and e...

Embodiment 2

[0049] According to the following steps, the active ingredients in the enzymatic amoxicillin mother liquor are comprehensively recovered:

[0050] (1) Concentrated amoxicillin mother liquor

[0051] Take 1000L of the mother liquor of amoxicillin synthesized by enzymatic method after the crystallization and separation of amoxicillin, and detect the content of each component in the mother liquor by high performance liquid chromatography, and the detection results are shown in Table 2 below. The pH of the mother liquor is adjusted to 8.5 with a volume fraction ratio of 25% concentrated ammonia, so that the solubility of various substances in the mother liquor is relatively high, ensuring that there will be no crystals in the nanofiltration concentration process; Dalton's nanofiltration membrane concentrates the mother liquor of amoxicillin to 98L by nanofiltration at 5-8°C. During this process, only some inorganic salts and a small amount of D-hydroxyphenylglycine pass through th...

Embodiment 3

[0064] According to the following steps, the active ingredients in the enzymatic amoxicillin mother liquor are comprehensively recovered:

[0065] (1) Concentrated amoxicillin mother liquor

[0066]Take 1000 L of the mother liquor of amoxicillin synthesized by enzymatic method after the crystallization and separation of amoxicillin, and detect the content of each component in the mother liquor by high performance liquid chromatography, and the detection results are shown in Table 3 below. Mother liquor pH is adjusted to 8.5 with 40% (wt %) sodium hydroxide solution, makes the solubility of various substances in the mother liquor all relatively high, has guaranteed that there will not be crystallization in the nanofiltration concentration process; Then adopt molecular weight cut-off The nanofiltration membrane of 300 Daltons concentrates the mother liquor of amoxicillin to 100L under the condition of 5-8°C. During this process, only some inorganic salts and a small amount of D-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com