Immobilized enzyme biological catalyst, preparation method and application

A biocatalyst and immobilized enzyme technology, applied in biochemical equipment and methods, immobilized enzymes, enzymes, etc., can solve the problems of easy detachment of enzymes, achieve the effects of improving catalytic activity, reducing the amount of enzymes used, and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the present invention is described in detail below:

[0029] 1, physical adsorption method prepares catalyst of the present invention:

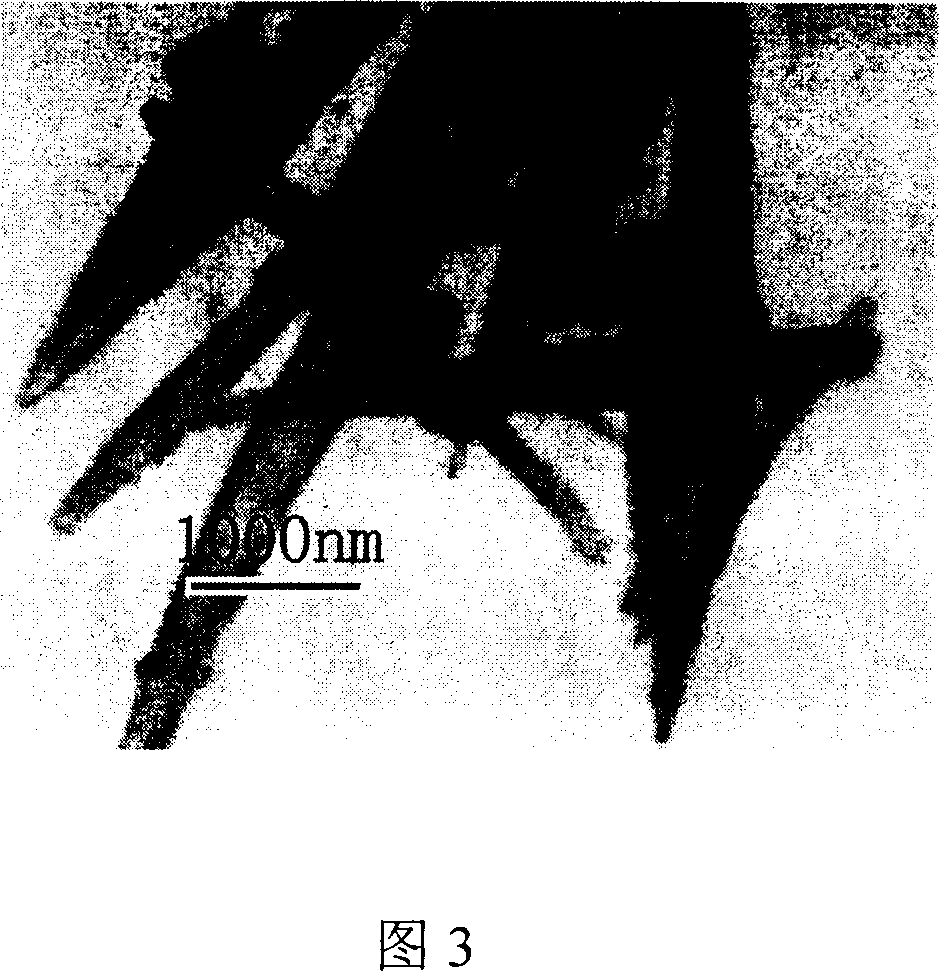

[0030] A certain weight of acicular CaCO 3 Add the particles into 50-200mL of deionized water, disperse them with an ultrasonic device, then add 10-50mL of ethanol and 0.01-3g of surfactant, and stir thoroughly for 15-30 minutes; then slowly add a certain amount of ethyl orthosilicate dropwise into the mixed solution, aged for 2-3 hours, filtered, washed several times with deionized water and ethanol, dried, calcined, and dissolved in hydrochloric acid to remove the template CaCO 3 , and finally made tubular hollow SiO 2 Mesoporous material carrier, spare; based on the weight percentage of the immobilized enzyme biocatalyst, add 80.00% to 99.99% of the carrier material of tubular hollow structure silica and 0.01% to 10.00% of at least one crystallizing enzyme or solution enzyme Into the deionized water, ace...

Embodiment 1

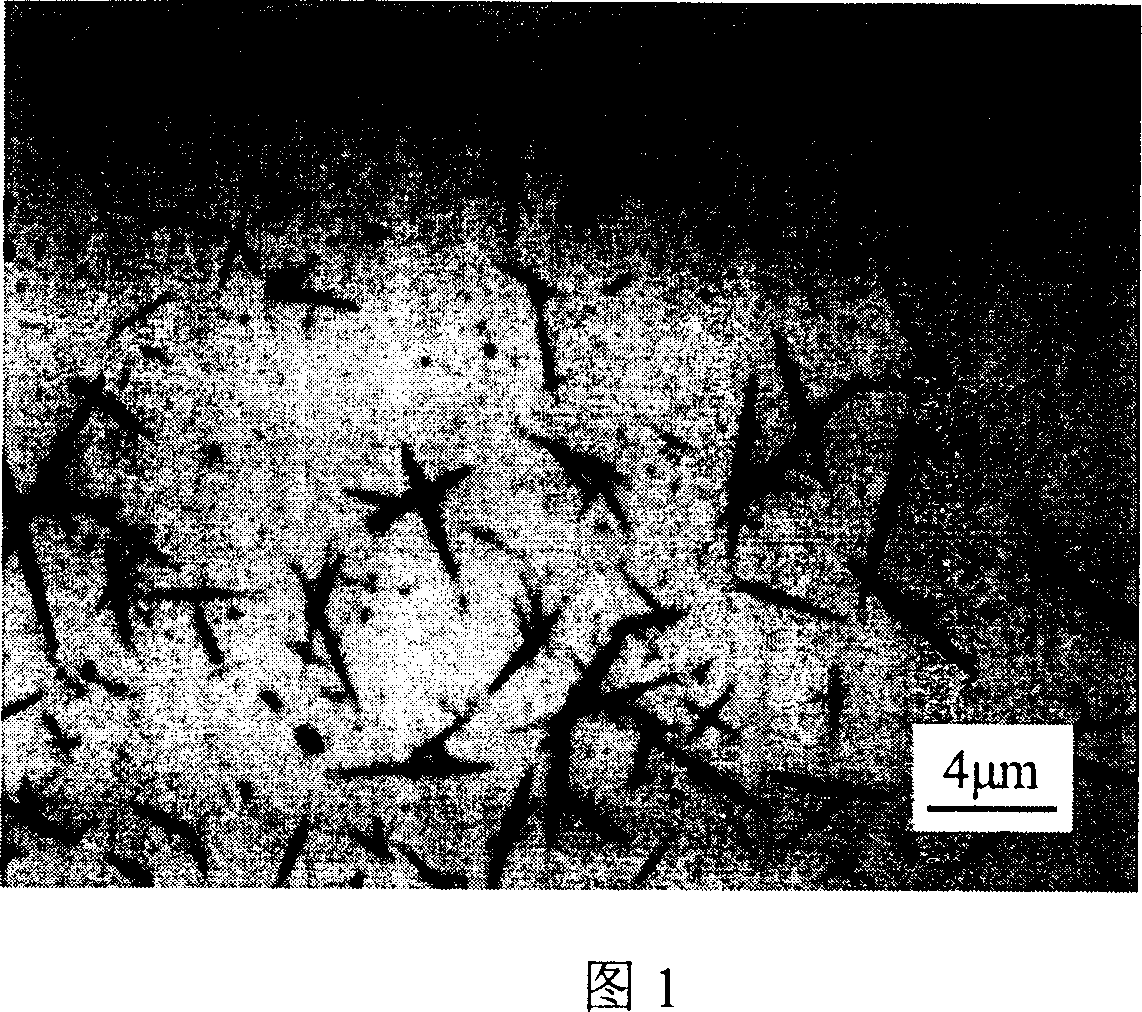

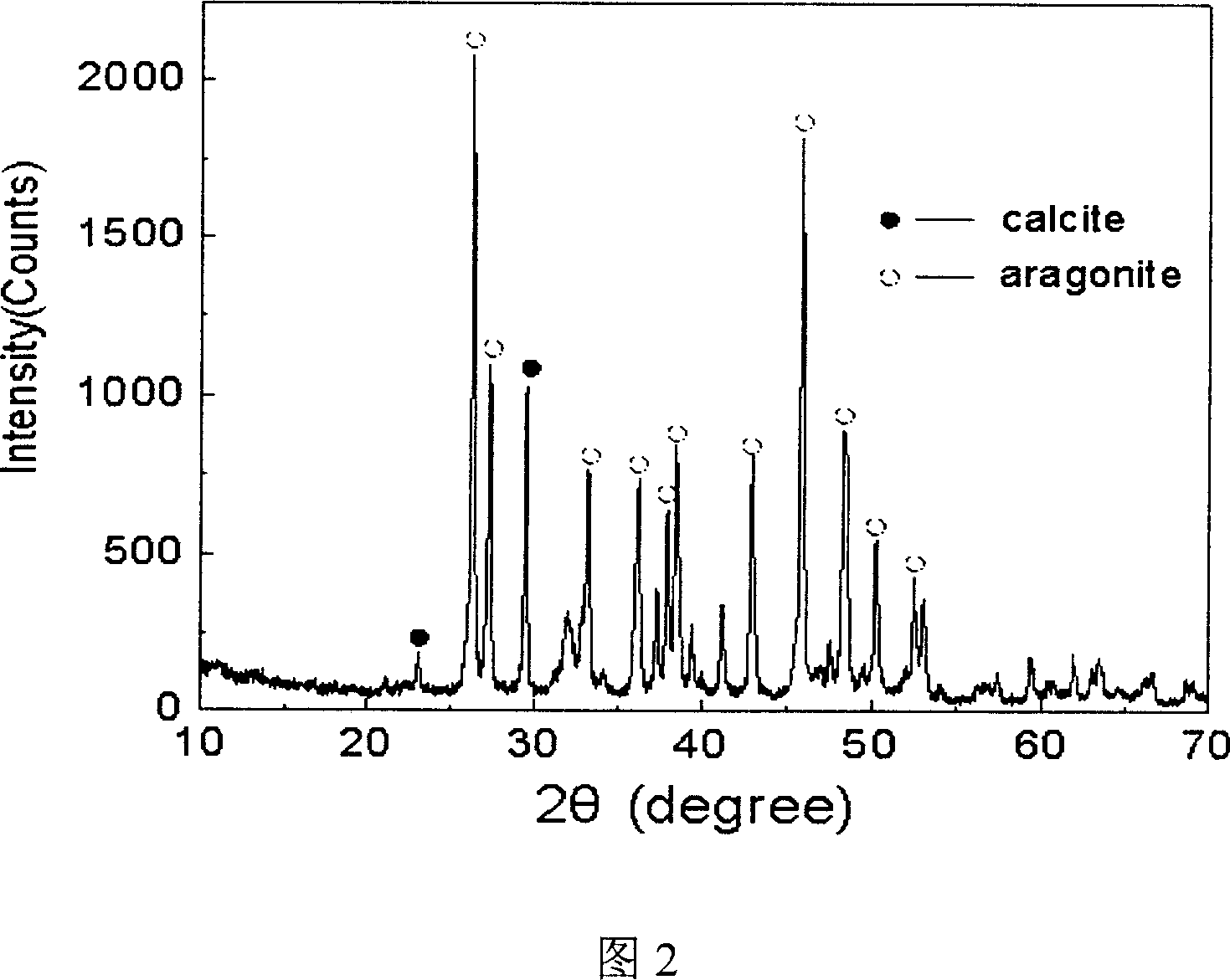

[0040] This example is to prepare the needle-shaped calcium carbonate template of the carrier: weigh a certain amount of industrial-grade quicklime, put it into hot water 7 to 8 times the quality of quicklime, and the temperature is about 70°C, digest it for a period of time, and separate it after cooling. Filter once with 80 mesh and 250 mesh standard sieves to obtain refined Ca(OH) 2 suspension, and then titrate the Ca(OH) with the calibrated EDTA standard solution 2 concentration, and then use the prepared Ca(OH) 2 The suspension was subjected to carbonization reaction, in this experiment, the gas phase (CO 2 Gas) is continuously fed in, the liquid phase circulates, contacts and reacts with the gas phase in the rotating packed bed. The specific steps of the carbonization reaction are as follows: (1) temperature adjustment: the rotating packed bed and the stirred tank are equipped with jackets, and the temperature of the reaction system is controlled by controlling the tem...

Embodiment 2

[0042] The acicular calcium carbonate that mainly contains striatum phase crystal form prepared by embodiment 1 is mixed with the suspension that concentration is 0.8mol / L, gets 200mL nano-calcium carbonate suspension and is placed in reactor, and starts to heat up and stir, stirring speed Control at 400-500r / min; prepare 500mL of sodium silicate solution with a concentration of 0.68mol / L and 10wt% dilute hydrochloric acid solution. When the temperature rises to 80°C, start to add sodium silicate solution dropwise, and add dilute hydrochloric acid at the same time, adjust the pH of the system between 8.5 and 9.5, and generate CaCO 3 / SiO 2 Core-shell structure materials. After all the sodium silicate solution is added dropwise into the system, stop adding acid, and stir and age at this reaction temperature, and the aging time is controlled at 4h, so that the SiO 2 in CaCO 3 Surface deposition, curing. The aged slurry was filtered, washed, dried at 105°C for 12h, and then c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com