Anti-explosion vacuum pressure varnished insulation apparatus and its technical method

A technology of vacuum pressure impregnation and insulation device, applied in the field of pressure vessels, can solve the problems of unsafe, unsmooth gas path, and high dielectric loss, and achieve the effects of improving service life, saving raw materials, and reducing dielectric loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

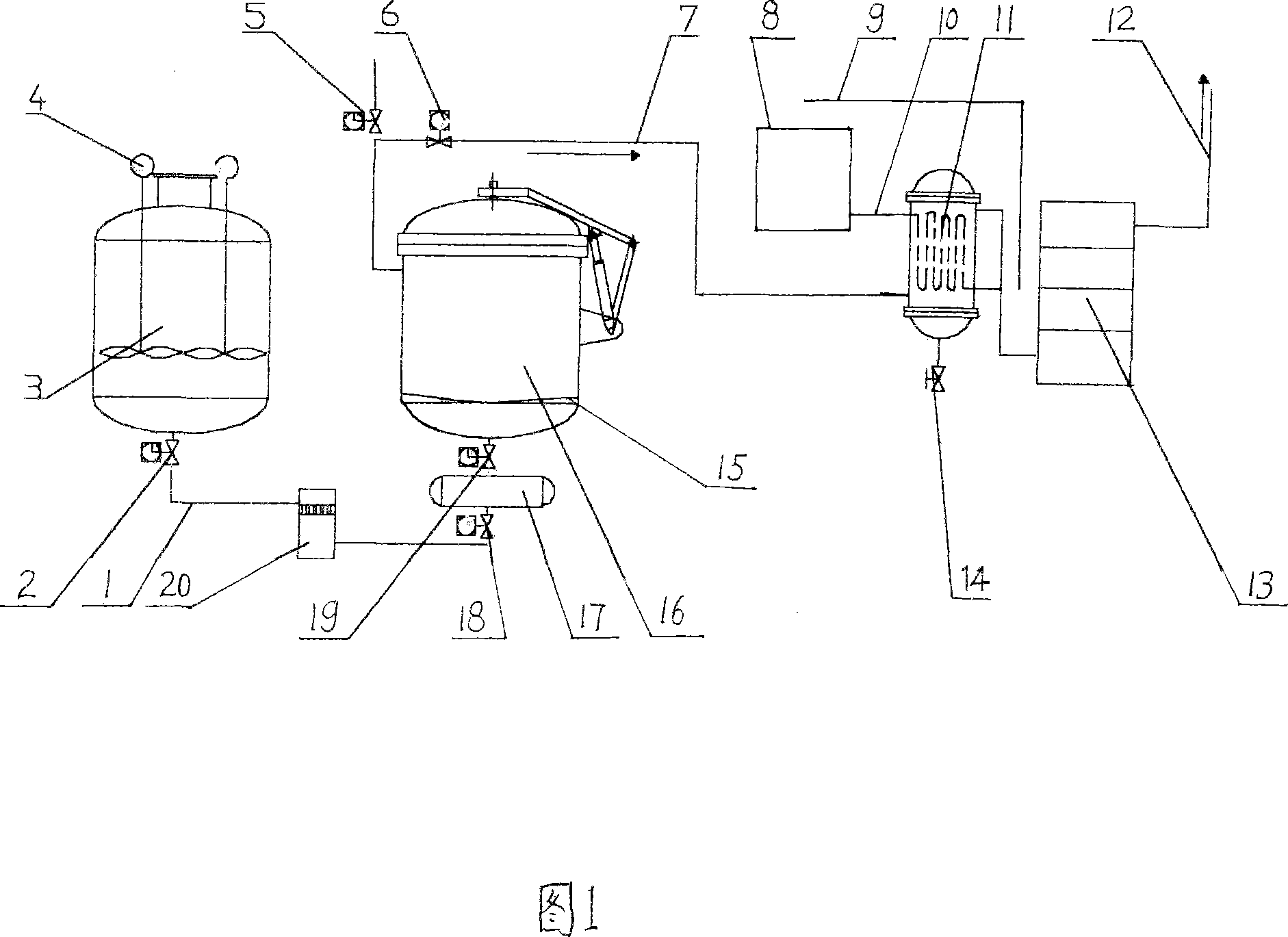

[0025] Referring to Figure 1, the labels in the figure are: paint delivery pipeline 1, paint delivery valve 2, paint storage tank 3, stirring motor 4, pressurized pneumatic valve 5, vacuum pneumatic valve 6, vacuum pipeline 7, refrigeration unit 8, water outlet Pipeline 9, water inlet pipe 10, condenser 11, sewage pipe 12, vacuum unit 13, drain valve 14, paint collection plate 15, paint dipping tank 16, paint collection tank 17, paint delivery and return valve 18, paint collection valve 19. Filter 20.

[0026] The explosion-proof vacuum pressure impregnation insulation device of the present invention is composed of a paint dipping tank 16, a paint storage tank 3, a vacuum unit 13, a refrigeration unit 8, a condenser 11, and a paint collection tank 17, wherein the condenser 11 is arranged in the paint dipping tank 16 On the vacuum pipe 7 between the vacuum unit 13, the condenser 11 is a tank body closed up and down, and a circulating cooling pipe is arranged in the tank body, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com