Low-odor high-transparency ultrahigh flowability polypropylene as well as preparation device and method thereof

A low-odor and fluid technology, applied in the field of modified plastics, can solve the problems of low ash, chemical degradation agent residues, low fluidity, etc., and achieve the effect of low yellow index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

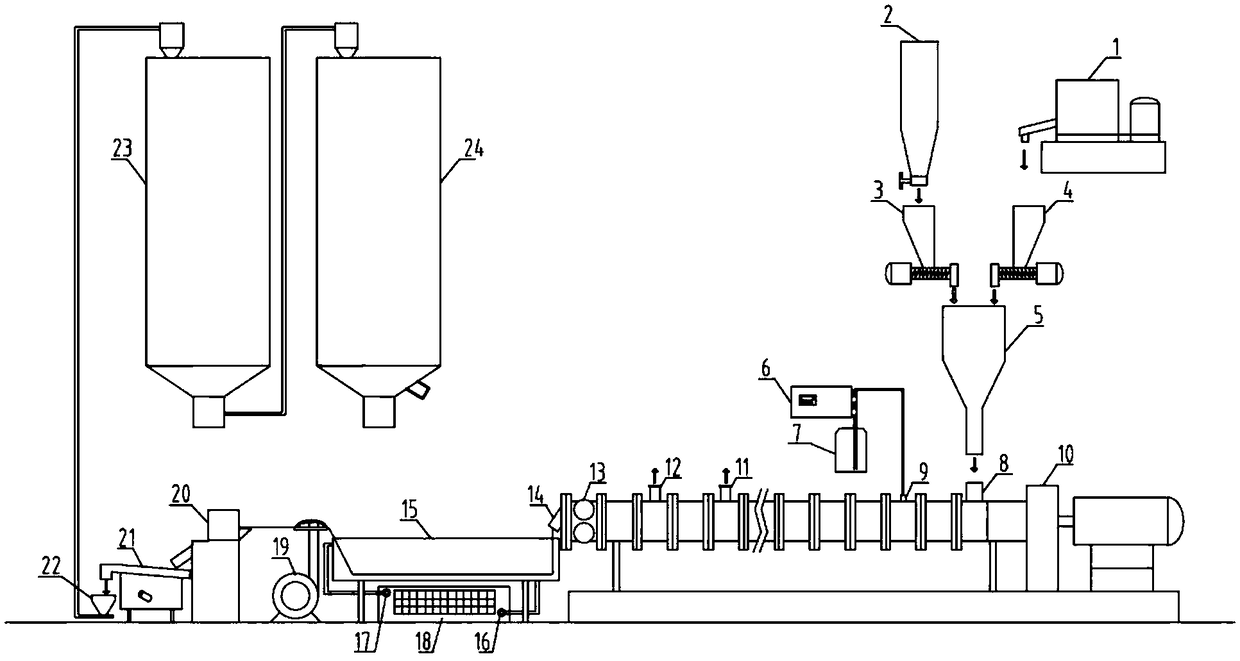

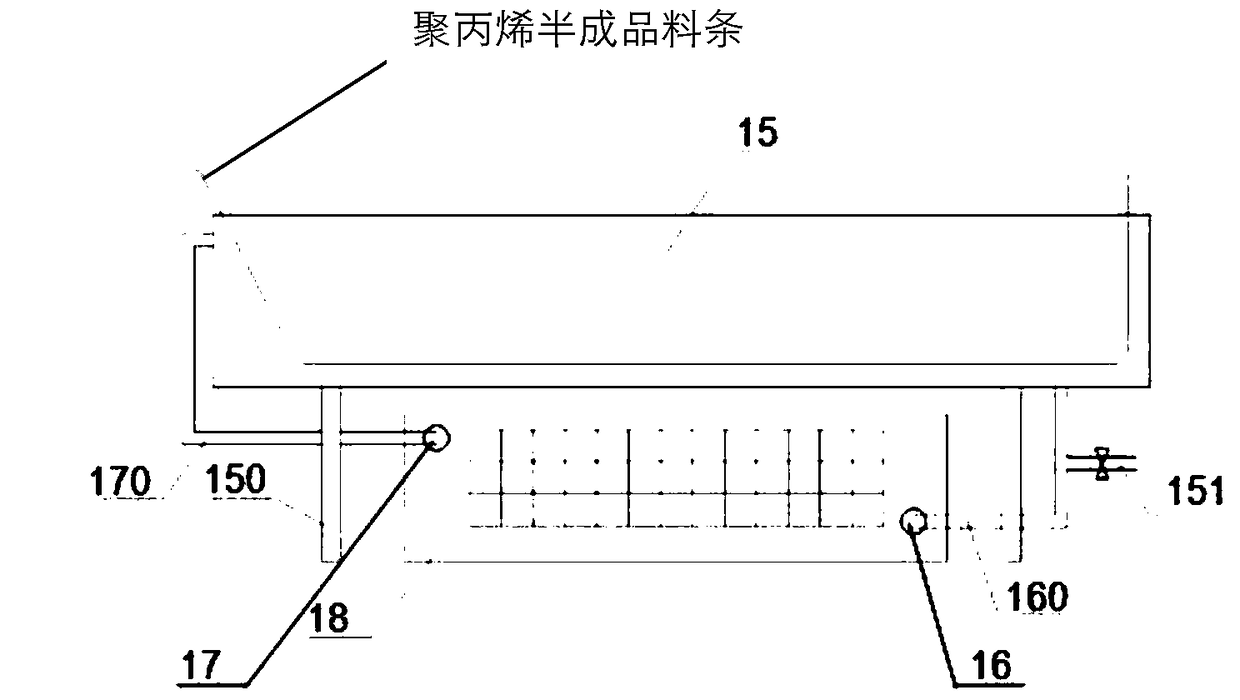

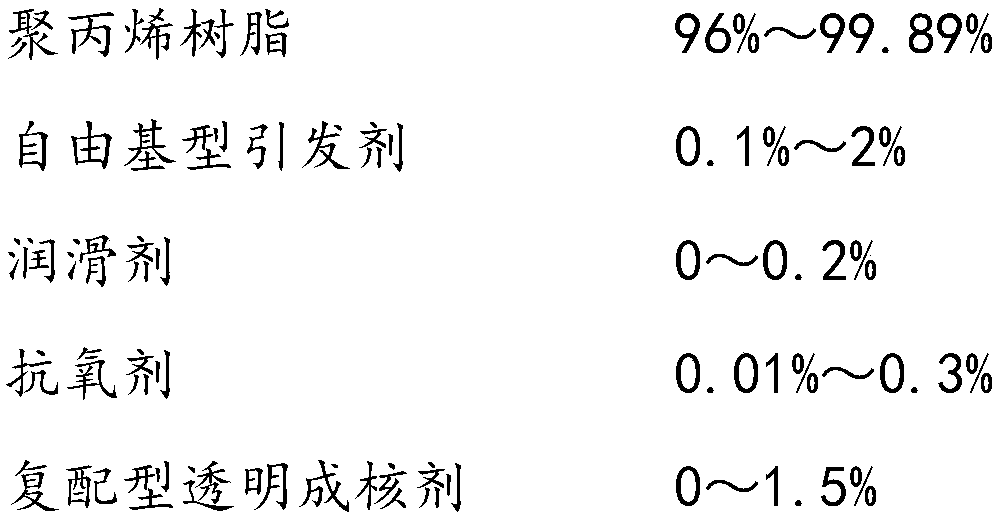

[0079] S1, the polypropylene powder (grade 225 powder) of 49.85kg, the lubricant EBS of 50g, the antioxidant 1010 of 50g, the antioxidant 168 of 50g are mixed in high-speed mixer 1, weigh 4 from 2# weight loss Put into the middle hopper 5; 50kg polypropylene pellets (brand Z30S) are put into the middle hopper 5 through 1# loss in weight scale 3; Setting extruder rotating speed is 350 rev / mins, and the total cutting speed of weight loss scale is 450kg / h, set Set the feeding ratio of 1# loss-in-weight scale and 2# loss-in-weight scale to 50% / 50%, and the material is fed to the extruder through the middle hopper 5;

[0080] S2, di-tert-butyl peroxide for free radical initiator in initiator tank 7, setting precision metering pump 6 flow rate is 30ml / min, pressure is that 3.50MPa injects twin-screw extruder 10, polypropylene is in organic peroxidation Under the action of species initiator, high temperature melting and screw shearing, free radical degradation reaction occurs, the mo...

Embodiment 2

[0087] S1, the polypropylene powder (brand name PP-H-225) of 49.85kg, the lubricant calcium stearate of 50g, the antioxidant 168 of 50g antioxidant 1076,50g are mixed in high-speed mixer, from Put 2# loss-in-weight scale into the middle hopper; put 50kg of polypropylene pellets (brand Z30S) into the middle hopper through 1# loss-in-weight scale; set the speed of extruder to 350 rpm, and the total feeding speed of loss-in-weight scale is 450kg / h, Set the feeding ratio of 1# loss-in-weight scale and 2# loss-in-weight scale to 50% / 50%, and feed the material to the extruder through the middle hopper;

[0088] S2, 2,5-dimethyl-2,5-bis(tert-butyl peroxide) hexane is used as a free radical initiator, and the flow rate of the precision metering pump is set to 24ml / min and the pressure is 3.00MPa to inject into the twin-screw extruder After exiting the machine, under the action of organic peroxide initiator, high temperature melting and screw shearing, the polypropylene undergoes free ...

Embodiment 3

[0095] The difference between this embodiment and Example 1 is: first, the grade of polypropylene powder is PP-H-045, and the lubricant is calcium stearate; second, the grade of polypropylene pellets is Y24; Its three, what free radical initiator adopted is two (tert-butyl peroxide diisopropyl) benzene; Its four, the flow rate of setting precision metering pump is 42ml / min, and pressure is 4.00Mpa; Its five, sink connection The set temperature of the chiller is 15°C.

[0096] In this embodiment, the product is extruded by an extruder, drawn, cooled, pelletized and dried. The physical properties of the product are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com