Gel composition for injection filling of skins and preparation method for gel composition

A gel composition and gel technology, applied in the field of gel composition and its preparation, can solve the problems of increasing the risk of organic solvents, not involving microgels of various particle size levels, and complicated preparation processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation process of cross-linked HA gel particles adopts simple and feasible processes such as freezing, crushing and sieving, and easily obtains microgels of different particle size grades, among which the small particle size grade gel is suitable for injection into the superficial layer of the skin dermis , Medium particle size gel is suitable for injection into the middle to deep layer of the skin dermis, and large particle size gel is suitable for injection into the subcutaneous layer, both of which have the cosmetic effect of filling wrinkles and repairing depressions. Therefore, the present invention is easy to prepare a series of gel compositions suitable for injection filling of different layers of skin.

[0039] Due to the use of weakly alkaline natural HA solution mixed with gel ice particles, the gel composition prepared by the present invention contains a small amount of natural HA, which can reduce the injection resistance when injecting the product. ...

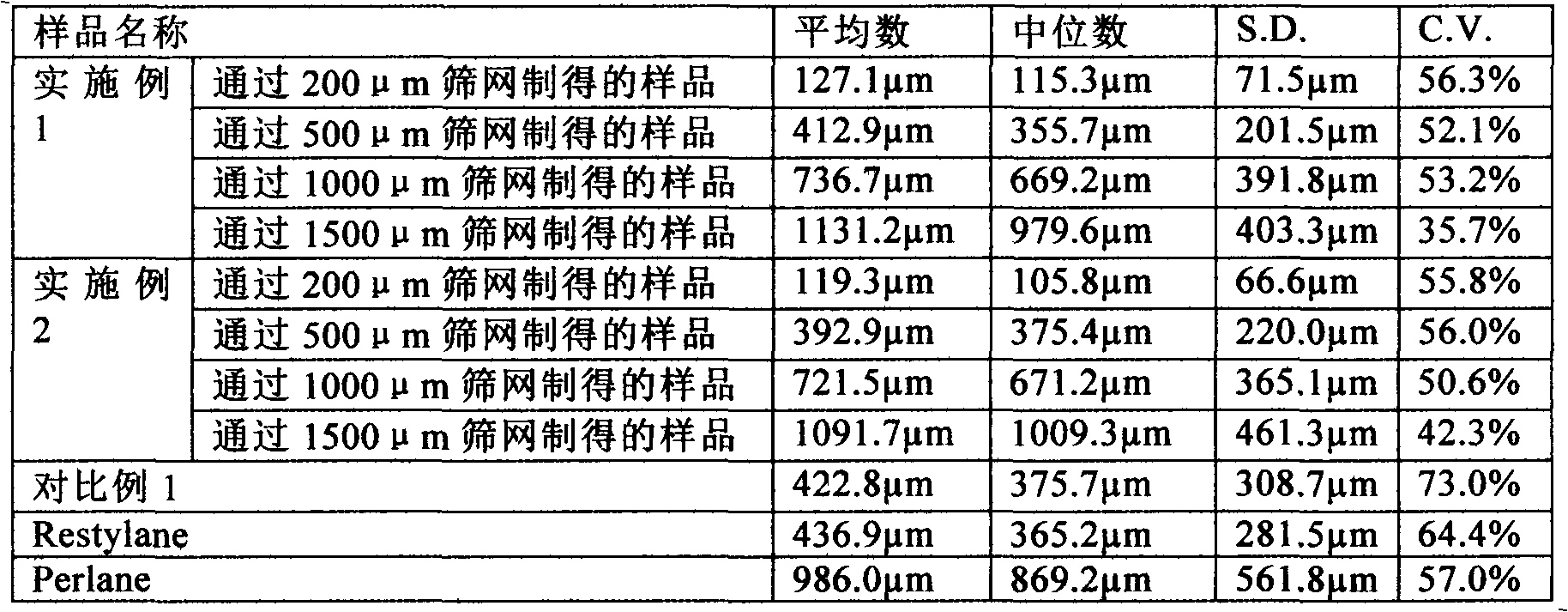

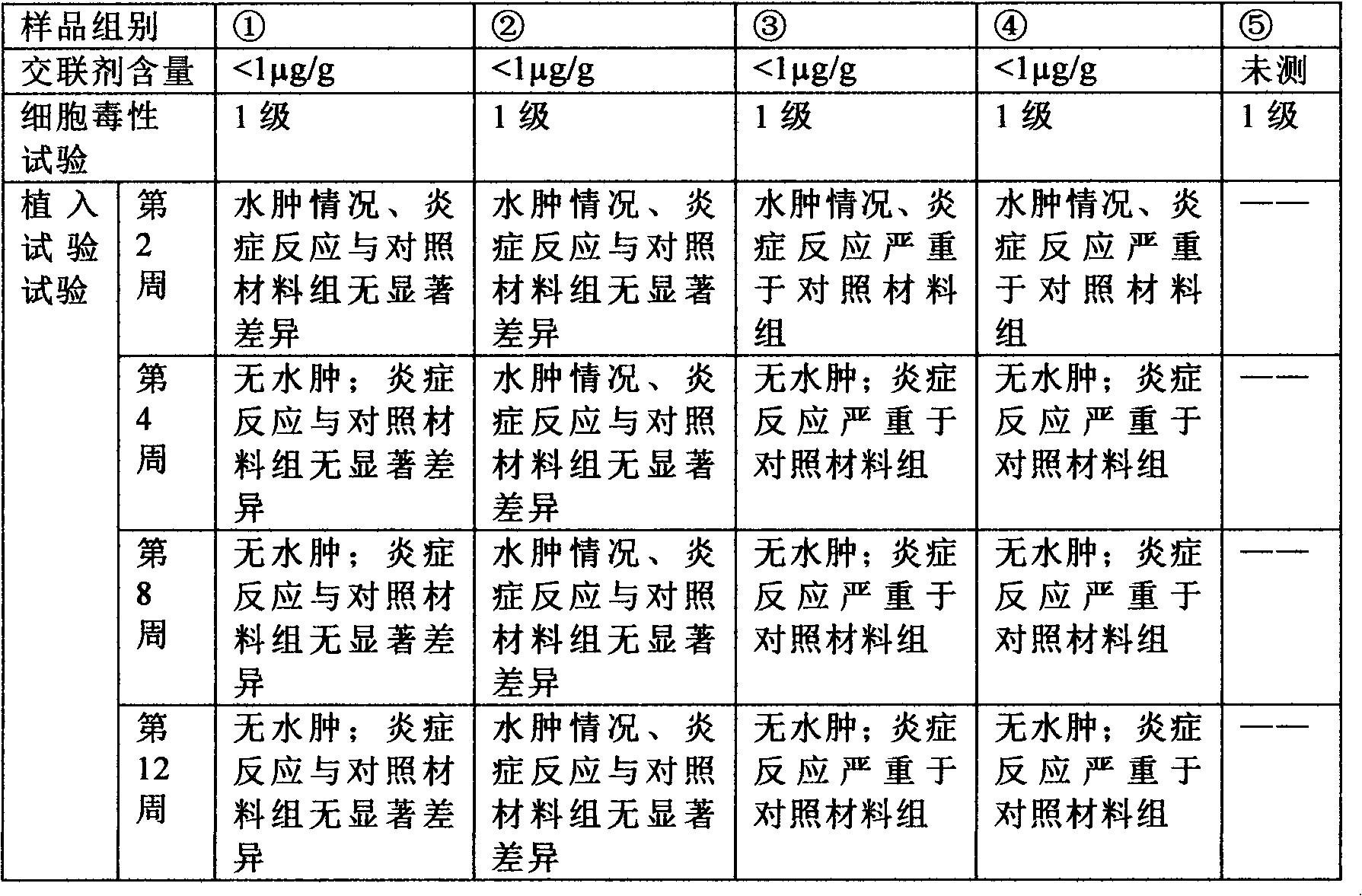

Embodiment 1

[0056] 5.0g hyaluronic acid (HA) raw material (molecular weight is 1 million Daltons), dissolved in 40ml of 0.2N NaOH solution, after dissolving, add 3ml of 1,4 butanediol diglycidyl ether, fully stir, place in 37 °C incubator for 4 hours, the cross-linked HA gel block is formed. The gel block was washed with distilled water and dialyzed, and the dialysate was changed 6 times in the following 3 days. Remove the distilled water, freeze the cross-linked HA gel block in a -50°C freezer for 24 hours, take out the cross-linked HA ice cube, set the temperature of the micronizer at -20°C in an environment of 4°C, and use the micronizer to quickly crush the ice cubes. Then pass through stainless steel mesh sieves with an average pore size of 200 μm, 500 μm, 1000 μm and 1500 μm in sequence, and collect gel ice particles with different particle size levels respectively. Add 50 ml of solution with pH 8.5, HA concentration 4%, and NaCl concentration 1.5% per 100 g of cross-linked HA ice ...

Embodiment 2

[0058] 5.0g of HA raw material (molecular weight is 1 million Daltons), dissolved in 50ml of 0.2N NaOH solution, after dissolving, add 4ml of 1,4 butanediol diglycidyl ether, fully stir, and place in a 32°C thermostat for 6 hours, That is, a cross-linked HA gel block is formed. The gel block was washed and dialyzed with distilled water, and the dialysate was changed 9 times in the next 3 days. Remove the distilled water, freeze the cross-linked HA gel block in a -50°C freezer for 48 hours, take out the cross-linked HA ice cube, set the temperature of the micronizer at -15°C in an environment of 4°C, and use the micronizer to quickly crush the ice cubes. Then pass through stainless steel mesh sieves with an average pore size of 200 μm, 500 μm, 1000 μm and 1500 μm in sequence, and collect gel ice particles with different particle size levels respectively. Add 50ml of solution with pH 8.9, HA concentration 3.5%, and NaCl concentration 1.5% per 100g of cross-linked HA ice particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com