Method for manufacturing printed circuit board edge connector

A manufacturing method and gold finger technology, which is applied in the directions of printed circuit, printed circuit manufacturing, and electrical connection formation of printed components, etc., can solve problems such as electroplating lead residues, and achieve the effect of solving electroplating lead residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Such as Figure 4 As shown, the manufacturing method of printed circuit board golden finger of the present invention comprises steps:

[0029] S 10. Form the gold finger electroplating lead and the gold finger area at one time on the printed circuit board, wherein the width of the adjacent part of the electroplating lead and the gold finger area is equal to the width of the gold finger area.

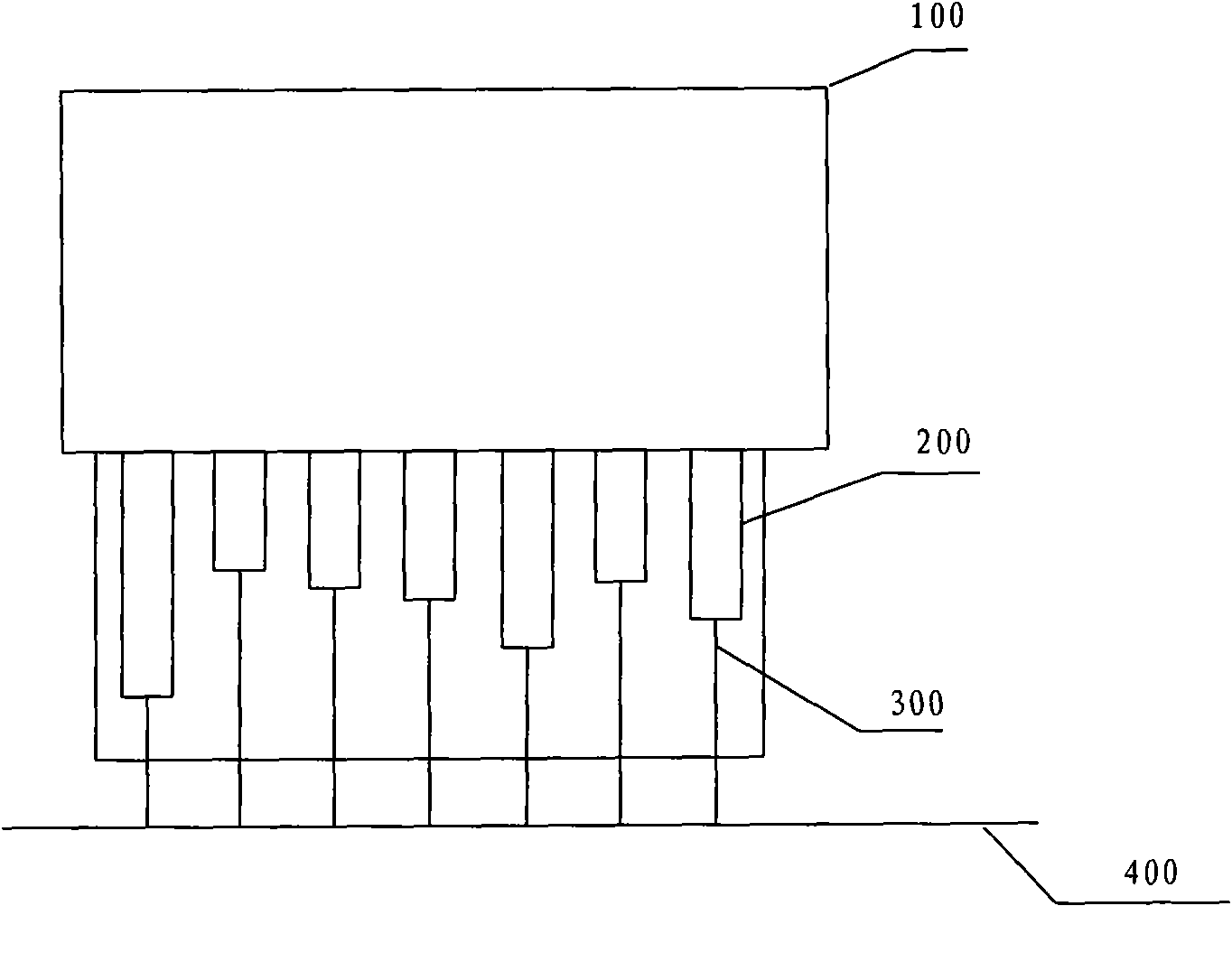

[0030] Such as Figure 5 As shown, when the printed wiring board 100 is transferred to the circuit pattern for the first time, the gold finger plating lead 300 and the gold finger area 600 on the printed wiring board 100 are formed once, and the electroplating lead 300 and the gold finger area The width of the adjacent portion 600 is equal to the width of the golden finger area 600 . In this embodiment, the gold finger electroplating lead 300 is preferably designed to be of equal width throughout, but the present invention is not limited thereto.

[0031] S20. Coating a coverin...

Embodiment 2

[0038] This embodiment provides a method for manufacturing a multi-stage graded leadless golden finger. The method for manufacturing the graded leadless gold finger in this embodiment will be described in detail below in conjunction with the accompanying drawings.

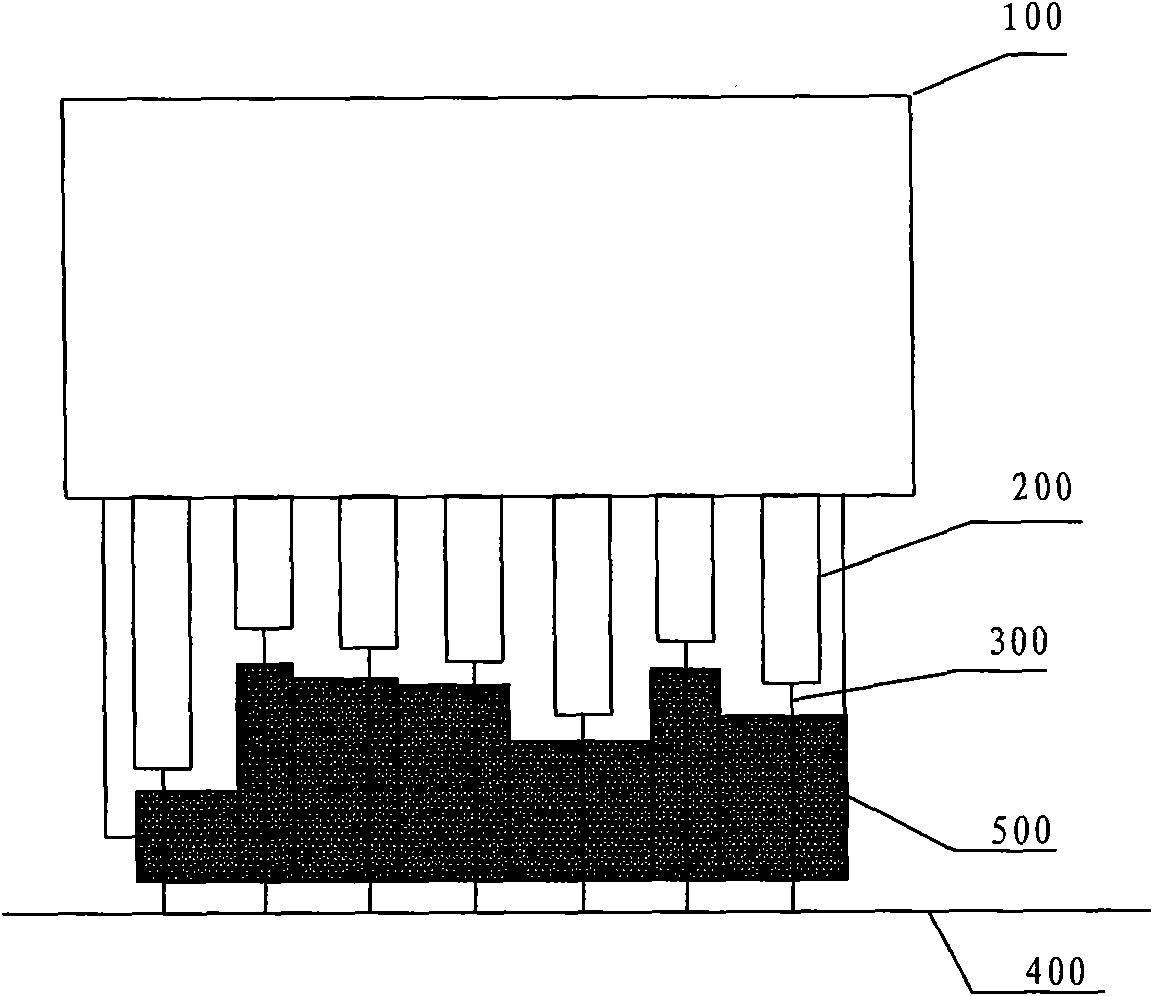

[0039] The manufacturing method of the graded leadless gold finger in this embodiment is basically the same as the manufacturing method of the printed circuit board leadless gold finger in the first embodiment above. The difference is that if Figure 9 As shown, when coating the cover, the electroplating lead 300 is coated with dry film or anti-plating ink 500; the gold finger area 600 is segmentally coated with anti-plating ink 500 to form a multi-stage graded gold finger electroplating reserved area 700 ; Cover the blue tape on the circuit pattern on the printed circuit board 100 except the gold finger area and the electroplated lead. When covering the anti-plating ink, it should also be noted that the length o...

Embodiment 3

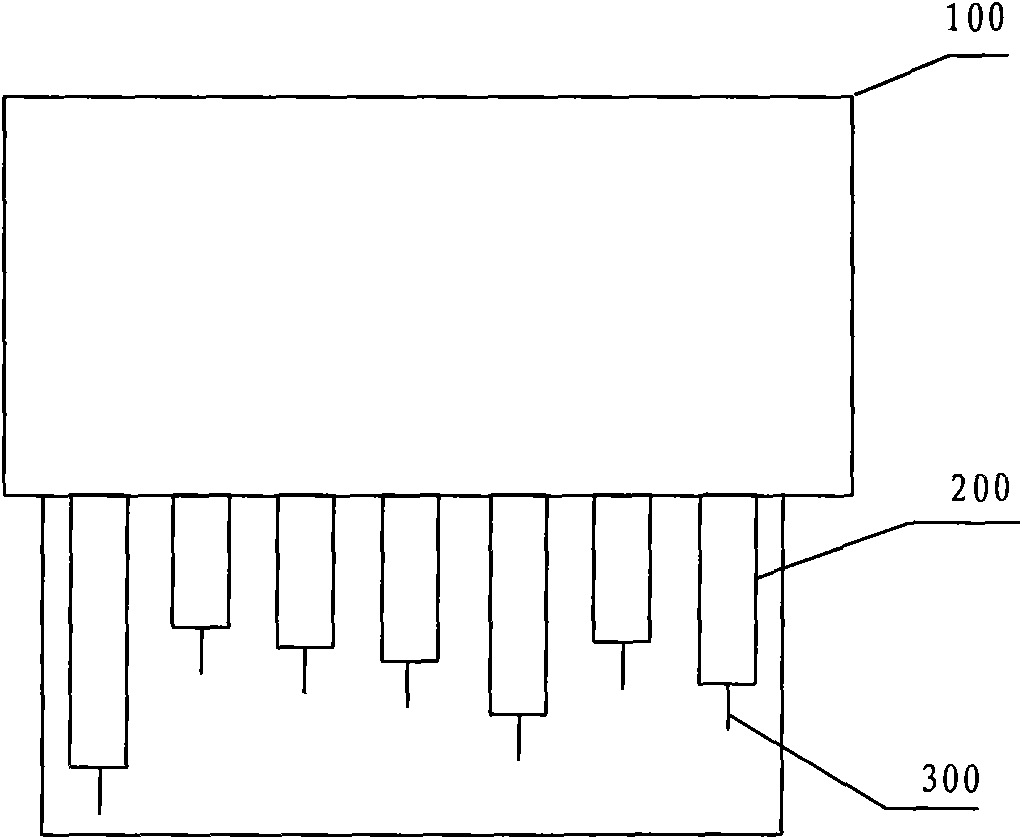

[0042] Such as Figure 11 As shown, in this embodiment, the connecting area between the gold finger plating lead 300 and the gold finger region 600 is made to have the same width, and the design of the connection area between the gold finger plating lead 300 and the main lead 400 can be smaller than the width of the gold finger region 600 ; By covering the electroplating ink 500 to the gold finger electroplating lead wire 300, a reserved area for gold finger electroplating is formed; before gold plating, other circuit pattern parts (except the gold finger and wire area) on the printed circuit board are covered with dry film or paste Protect it with blue tape, and then electroplate nickel and gold. After the electroplating is completed, remove the blue tape of the anti-plating ink and graphic part; and cover other circuit graphic parts (except gold finger wires) on the printed circuit board. The dry film is specially etched for gold finger wires, and the production of leadless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com