Process for preparing cell-class mischmetal by fused salt electrolysis process and device therefor

A mixed rare earth and molten salt electrolysis technology, which is applied in the field of rare earth product preparation, can solve the problems of unstable distribution of mixed rare earth metals, pollute the environment, cannot meet the requirements, and achieve long-term stable physical and chemical properties of electrolytes, low impurity content, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention is based on rare earth oxide (La 2 o 3 23-33%, CeO 2 47-57%, Pr 6 o 11 3-7%, Nd 2 o 3 12-18%) as raw materials, rare earth fluorides (lanthanum fluoride 48-52%, cerium fluoride 33-37%, praseodymium fluoride 2-4%, neodymium fluoride 9-13%), lithium fluoride binary The system is an electrolyte, the solubility of the oxide in the melt is 2-5%, and the mixed rare earth oxide is electrolyzed by a tungsten cathode to obtain the battery grade mixed rare earth metal.

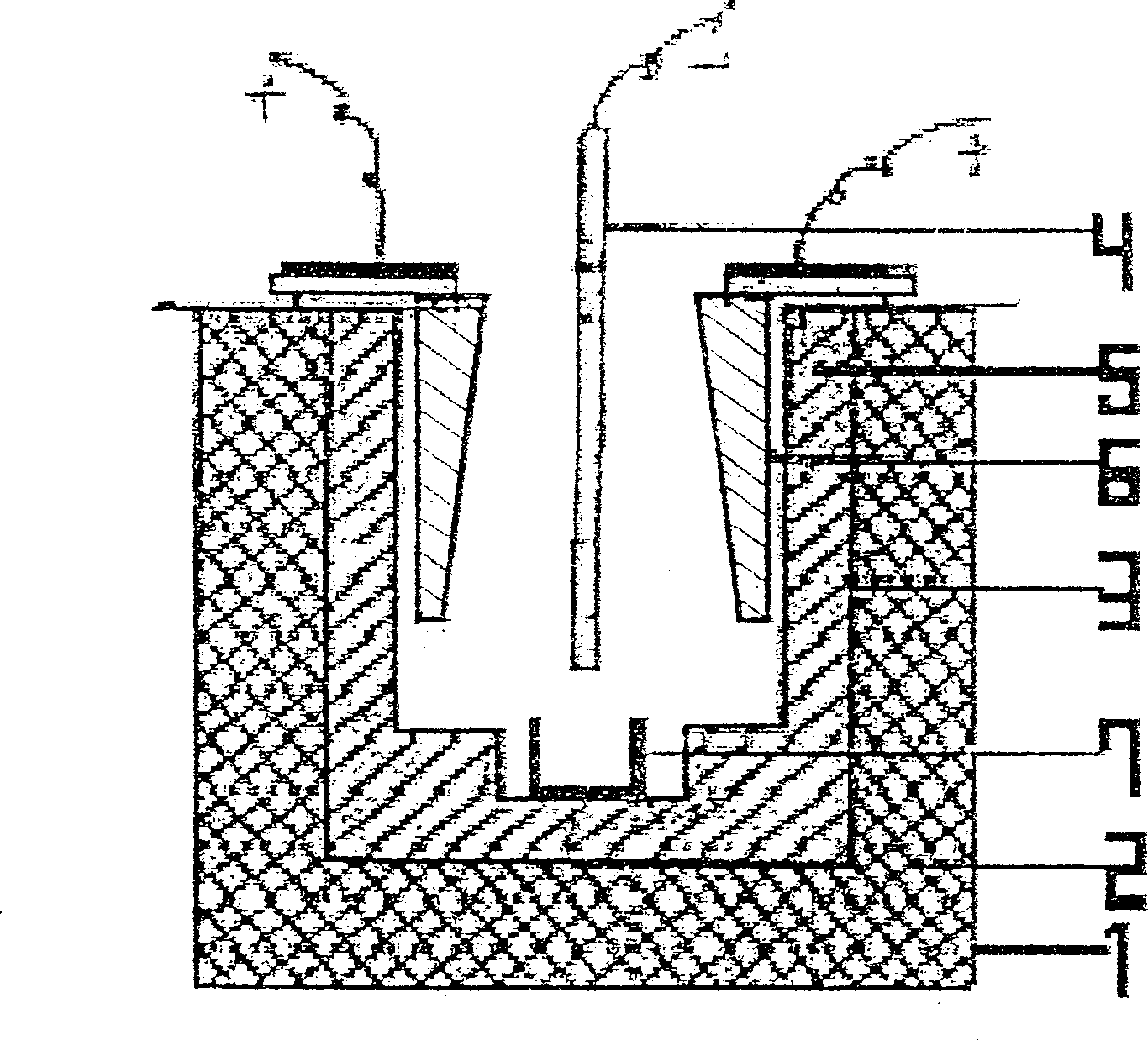

[0026] Equipment for producing battery-grade mixed rare earth metals by molten salt electrolysis, including casing 1, insulation material 2, inner protective casing 3, cathode 4, silicon carbide combined with silicon nitride material electrolytic cell 5, anode 6, receiver 7, attached to the electrolytic The shape of the anode 6 on the inner surface of the tank 5 is an inverted cone, and the electrolytic tank 5 is made of silicon carbide and silicon nitride materials. After the elec...

Embodiment 2

[0033] The present invention is based on rare earth oxide (La 2 o 3 26-30%, CeO 2 50-54%, Pr 6 o 11 3-7%, Nd 2 o 3 13-17%) as raw materials, rare earth fluoride (lanthanum fluoride 49-51%, cerium fluoride 34-36%, praseodymium fluoride 2-4%, neodymium fluoride 10-11%), lithium fluoride binary The system is an electrolyte, the solubility of the oxide in the melt is 2-5%, and the mixed rare earth oxide is electrolyzed by a tungsten cathode to obtain the battery grade mixed rare earth metal.

[0034] Equipment for producing battery-grade mixed rare earth metals by molten salt electrolysis, including casing 1, insulation material 2, inner protective casing 3, cathode 4, silicon carbide combined with silicon nitride material electrolytic cell 5, anode 6, receiver 7, attached to the electrolytic The shape of the anode 6 on the inner surface of the tank 5 is an inverted cone, and the electrolytic tank 5 is made of silicon carbide and silicon nitride materials. After the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com