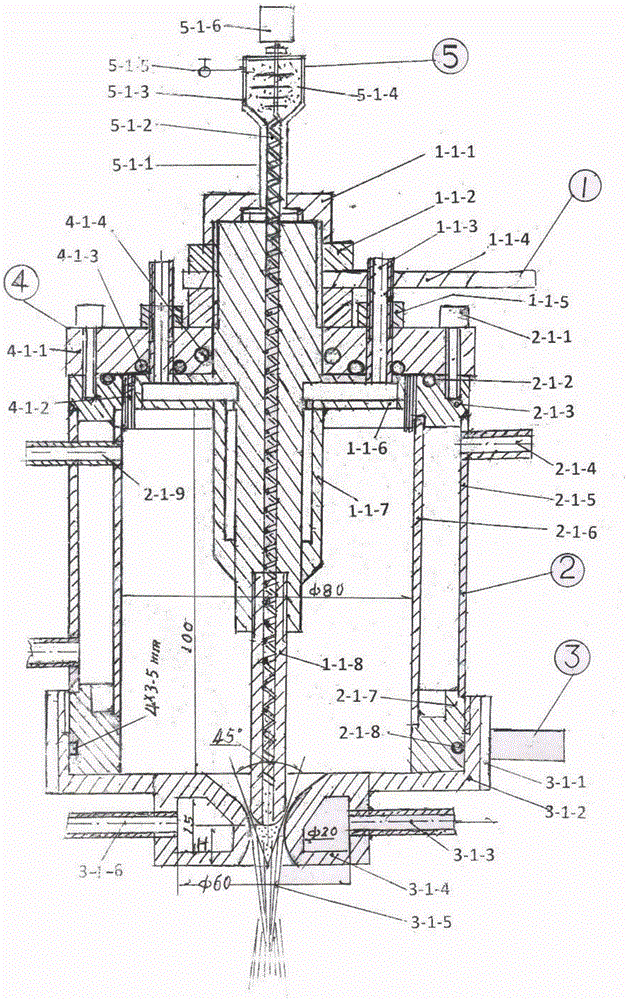

Direct-current argon arc plasma powder spray gun and manufacturing method

A plasma and argon arc technology, applied in the direction of fusion spraying, metal material coating process, coating, etc., can solve the problem that the conveying mechanism cannot ensure continuity, it is difficult to ensure uniform heating of all particles, and it is difficult to ensure stable droplet quality and temperature and other issues, to achieve the effect of improving the quality stability of the coating, improving the stability, and expanding the technical application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] Now design and manufacture a water-cooled powder spray gun with 40KW (65V, 600A) and powder spraying speed of 40-60g / min.

[0069] The nickel-based alloy powder used has a specific gravity d=2.6g / cm 3 , the working gas is high-purity argon.

[0070] It should be done as follows:

[0071] 1 Hollow tungsten cathode system design

[0072] 1.1 Parameter Design of Hollow Helical Spring

[0073] a: Assume that the outer diameter of the hollow coil spring is D=4mm, and the spring is wound with a spring steel wire with a diameter of Φ=0.5mm. The spacing h=4mm between the spring wires is calculated according to the formula (1) dw=K / 4 D2 h d v, where: K=1, D=0.4cm, h=0.4cm, d( Powder bulk specific gravity) = 2.6g / cm 3 , then dw=0.05026·2.6·v=0.13069·v

[0074] b: The speed of the speed-regulating motor is set to v=500r / min, then dw=65.34g / min, which meets the requirements, so the speed-regulating motor is selected as a speed of 0-1500r / min and a power of 500 watts.

[0075...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com