Manufacture method of annular barium-tungsten cathode emitter

A barium-tungsten cathode and a manufacturing method are applied in the manufacturing field of annular barium-tungsten cathode emitters, which can solve problems such as copper residues, and achieve the effects of low production cost, obvious application prospects, and deformation avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

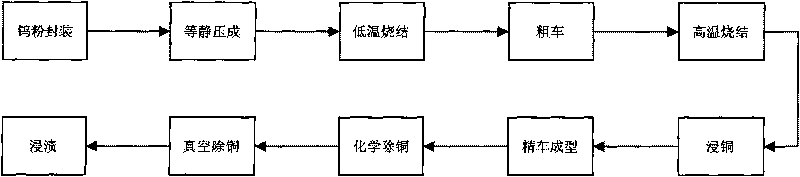

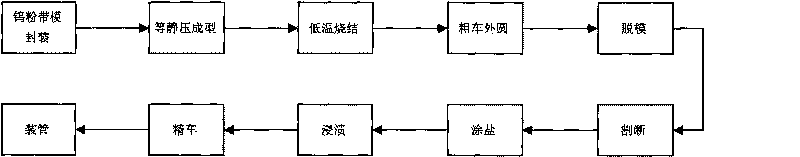

Method used

Image

Examples

Embodiment 1

[0026] 1. Design the mold according to the cathode size.

[0027] Such as image 3 The cathode emitter of a certain type of magnetron shown is designed with an outer diameter of 10 mm, an inner hole diameter of 8 mm, and a length of 5 mm. After calculation, the size of the rough body of the sponge tungsten body is determined to be 11 mm in diameter of the outer circle, 7.5 mm in diameter of the inner hole, and 6 mm in length. Design tungsten billet pressing molding die such as Figure 4 As shown, the outer diameter of the core is 7.5 mm. Design brass jackets such as Figure 5 As shown, its bore diameter is 11 mm. Design the elastic centering fixture as Figure 6 As shown, the outer diameter of the expansion head is 7.88 mm.

[0028] 2. Put the tungsten billet forming mold into the latex sleeve, fill it with tungsten powder, fill it up and seal it with wire rope.

[0029] 3. Put the packaged workpiece into the hydraulic press, turn on the machine and increase the pressur...

Embodiment 2

[0037] 1, with embodiment 1.

[0038] 2. Put the tungsten billet forming mold into the latex sleeve, fill it with tungsten powder, fill it up and seal it with wire rope.

[0039] 3. Put the packaged workpiece into the hydraulic press, turn on the machine and increase the pressure to 2T / cm 2 , holding pressure for 2min for isostatic pressing.

[0040] 4. Clean the pressed workpiece with cleaning solution, remove the latex tube, take out the tungsten billet with the mold and put it in a tungsten mesh hydrogen furnace, and heat it to 1000°C for low-temperature sintering.

[0041] 5. Clamp the sintered tungsten billet with mold on the lathe. The diameter of the outer circle of the car reaches 11 mm. Remove the pressing die and cut to make the length reach 6 mm. The diameter of the inner hole is naturally formed by the pressing die to obtain a rough car. Tungsten billet.

[0042] 6. Put the rough car tungsten billet into the tungsten mesh hydrogen furnace, heat it to 1900℃, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer circle diameter | aaaaa | aaaaa |

| Bore diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com