Storage film-coating dipped barium-tungsten cathode and preparation method

A barium tungsten cathode and cathode technology is applied in the field of electric vacuum to achieve the effects of increasing emission current density, increasing storage capacity and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

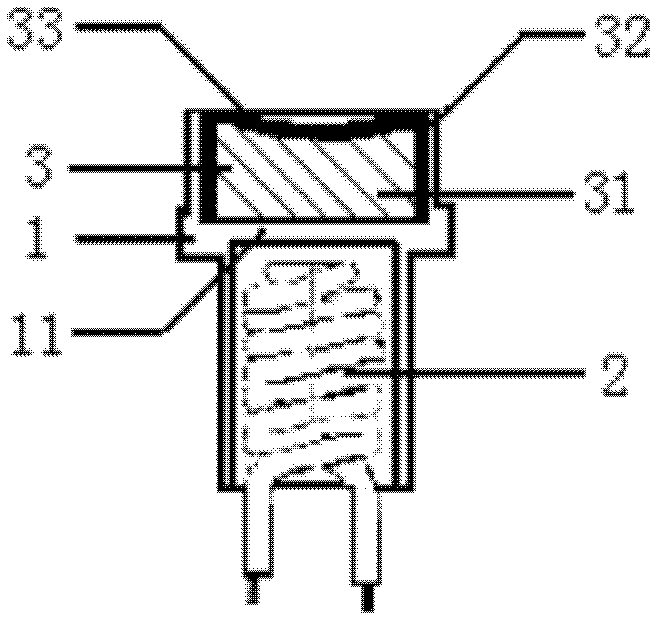

[0021] Such as figure 1 As shown, it is a schematic diagram of the structure of the storage-type film-impregnated barium-tungsten cathode of the present invention, which is composed of a molybdenum cylinder 1, a heater 2, and a cathode 3. The partition 11 in the molybdenum cylinder 1 divides the interior of the molybdenum cylinder 1 into two cavities. A heater 2 is fixedly connected in one cavity, and the lead wire of the heater 2 protrudes from the outer end; a cathode 3 is fixedly connected in the other cavity. Among them, the cathode 3 is axially divided into two layers of tungsten sponge matrix 31, 32, the inner layer tungsten sponge matrix 31 is connected with the partition 11, and the inner layer has a pore size of 40%-45%; the outer layer tungsten sponge matrix 32 has a pore size of 22%-24%. On the outer end surface of the outer tungsten sponge matrix 32, a layer of Os-Ir-Al film 33 is covered.

[0022] The specific technological process of the preparation of the stor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com