Electroplated diamond bur and manufacturing method thereof

A technology of electroplating diamonds and manufacturing methods, which is applied in the direction of electrolytic coatings, dental tools, coatings, etc., can solve the problems of bur failure, diamond abrasive grain peeling, poor hardness and wear resistance, etc., and achieve good holding force and long service life , the effect of high hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0044] Embodiment 1: Preparation of nickel-titanium dental bur

[0045] The preparation of the nickel-titanium dental bur of the new structure is carried out as follows:

[0046] (1) The nickel-titanium alloy bur matrix was prepared by pulling corrosion method.

[0047] (2) Pretreatment of nickel-titanium alloy dental bur substrate

[0048] a. Insulate the non-plated part (handle and neck) of the bur with a heat shrinkable tube;

[0049] b. Put the insulated nickel-titanium alloy bur base into acetone solution, ultrasonically clean it for 15 minutes, and then rinse it with distilled water.

[0050] c. Put the base body of the bur into 80°C lye (containing NaOH 40g / l, NaOH 2 CO 3 30g / l, Na 3 PO 4 25g / l and Na 2 SiO 3 5g / l) for 20 minutes, then ultrasonically cleaned for 10 minutes;

[0051] d, washed with water until the pH is 7.0;

[0052] d. Ultrasonic cleaning in distilled water for 15 minutes;

[0053] e. Blow dry with a hair dryer for later use.

[0054] (3)...

specific Embodiment approach 2

[0077] Specific implementation mode 2: Characterization of nickel-titanium alloy substrate electroplated diamond bur

[0078] (1) Observation of the surface morphology of the bur

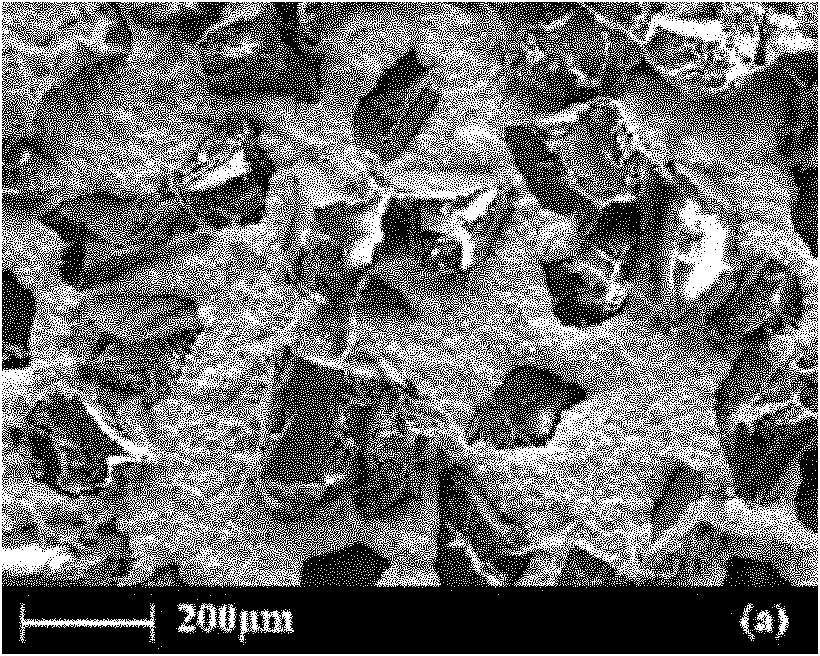

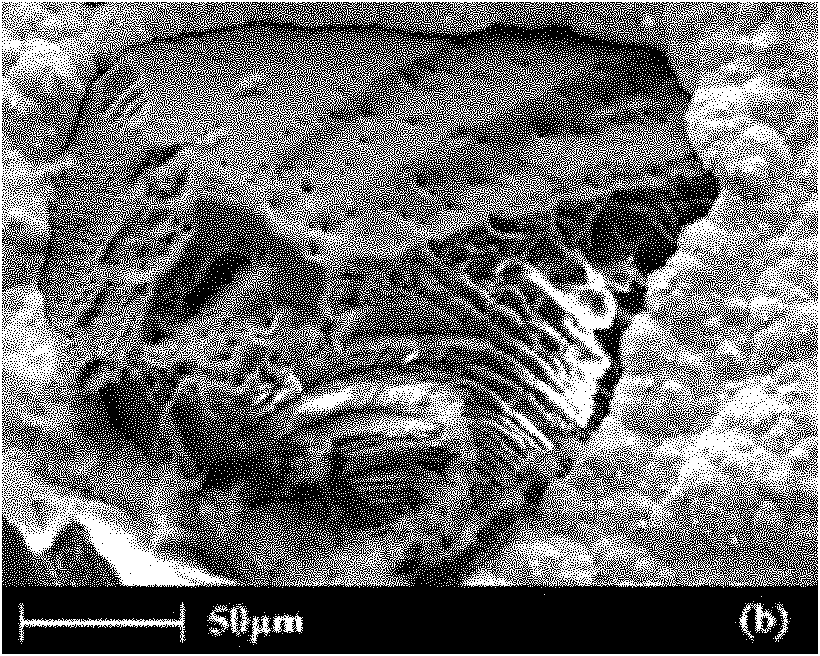

[0079] The surface morphology of the bur is shown in Fig. 2(a)-(c). It can be seen from the figure that the micro-diamond particles are evenly distributed on the surface of the nickel-titanium alloy bur, properly embedded, and well combined with the Ni-P / nano-diamond composite coating. Figure 2(c) is a backscattered electron image, in which black represents diamond and white represents Ni-P coating. It can be seen that throughout the composite coating, nano-diamonds are uniformly dispersed in Ni-P coating.

[0080] (2) Evaluation of cutting efficiency of bur

[0081] Made of machinable glass ceramics The rod is used as the cutting substrate to test the cutting performance, and its performance parameters are similar to human enamel. The test conditions are: the speed of the mobile phone is 340,0...

specific Embodiment approach 3

[0082] Specific implementation mode 3: Preparation of electroplated diamond bur with new structure of stainless steel substrate

[0083] The preparation of the new structural stainless steel substrate dental bur is carried out according to the following steps:

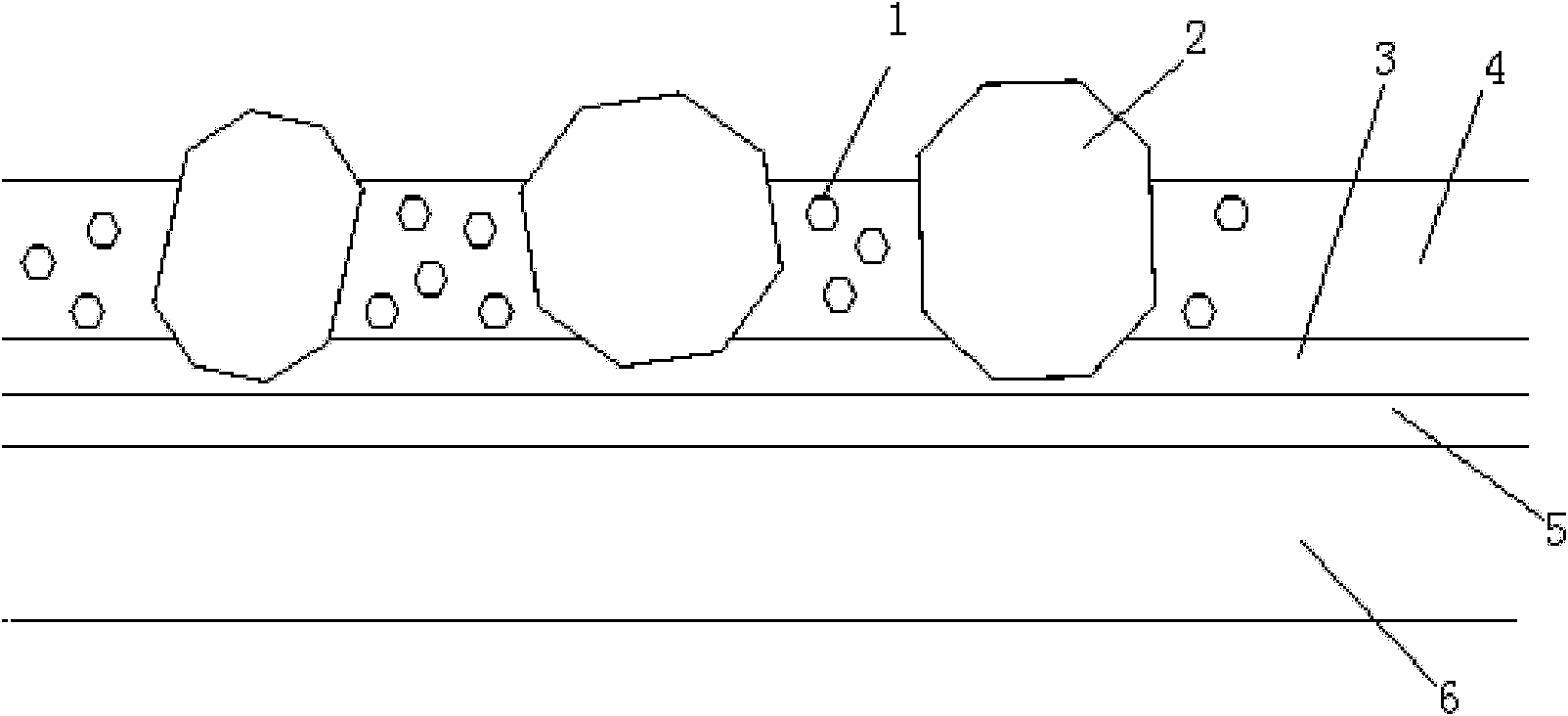

[0084] A stainless steel bur body, including a head, a neck and a shank, is prepared by machining. The structure of the multi-element multi-layer composite coating consists of the base pure nickel coating / nickel-phosphorus alloy sand coating / nickel-phosphorus-nano-diamond composite thickening coating. Before electroplating, the cleaned stainless steel bur substrate was treated with NaF and HNO 3 mixed solution (HNO 3 100g / L, NaF 4g / L) for ultrasonic etching activation.

[0085] Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com