Chirp grating tuner based on magnetoconstriction

A magnetostrictive and chirped grating technology, applied in the field of optical communication, can solve the problems of slow response speed of chirped Bragg grating and achieve the effect of dynamic dispersion compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

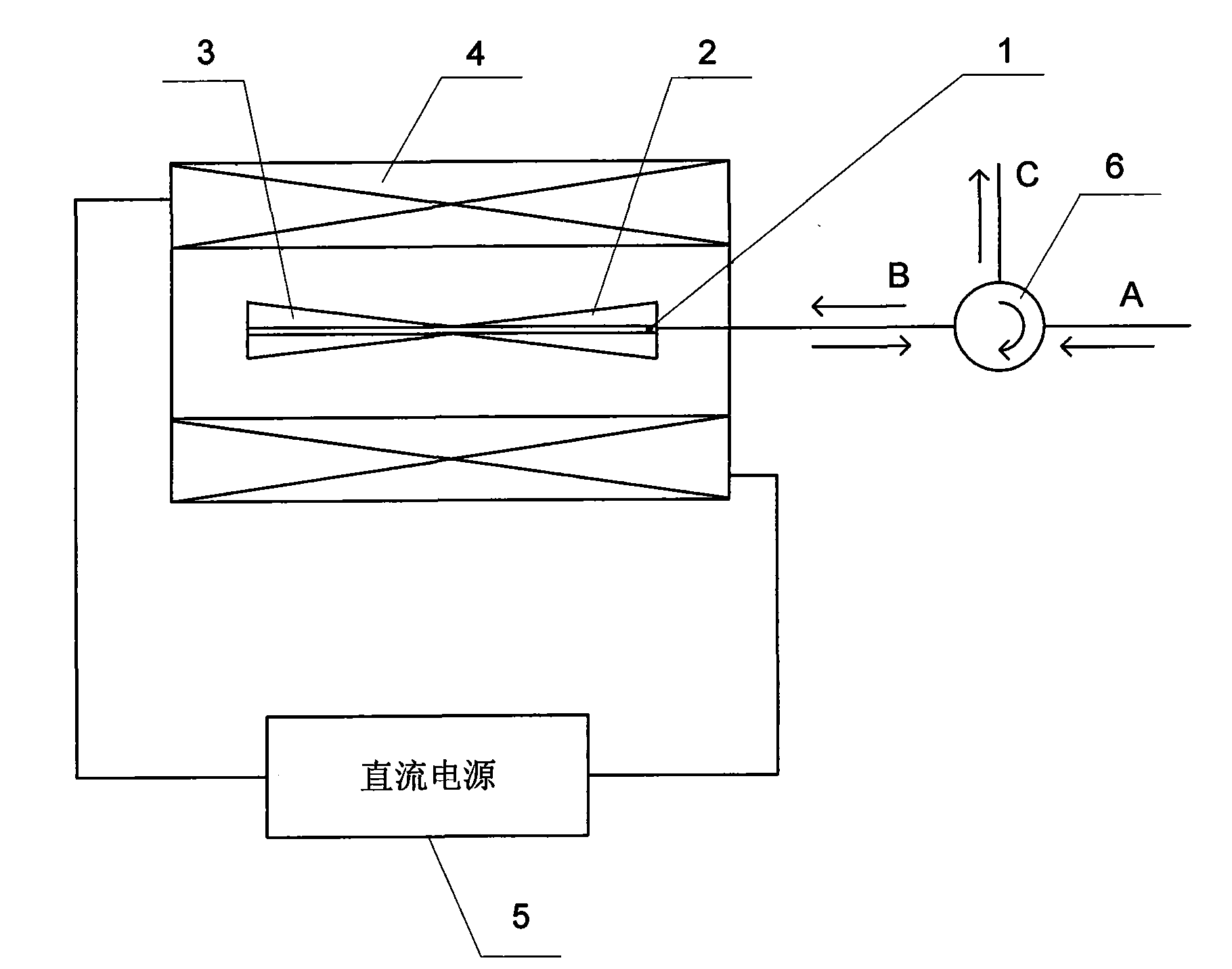

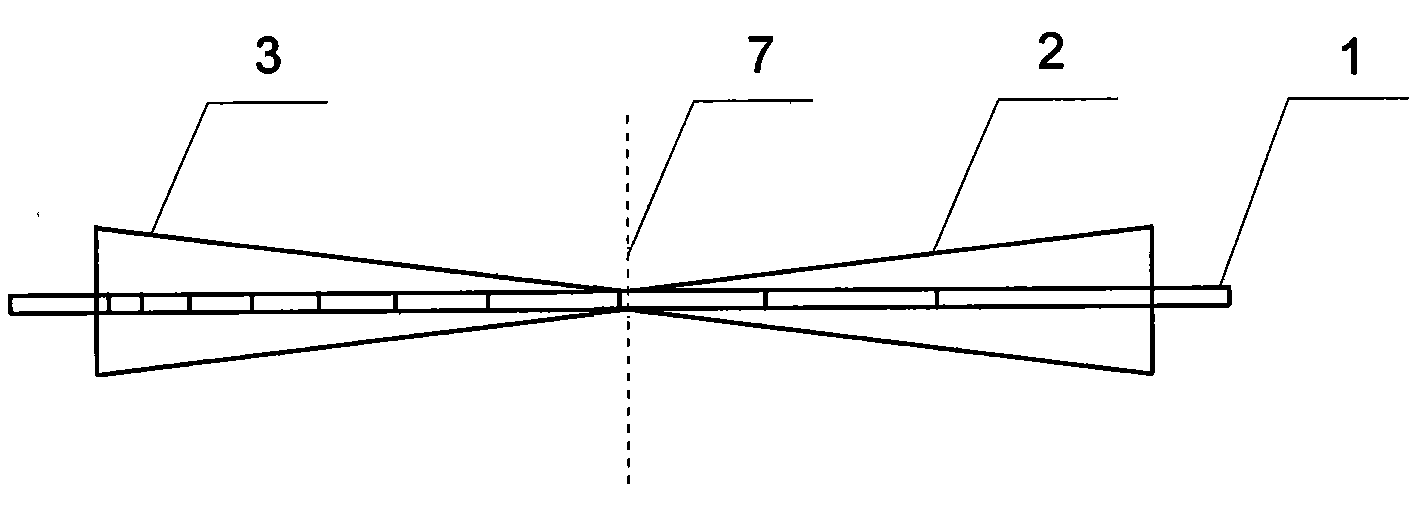

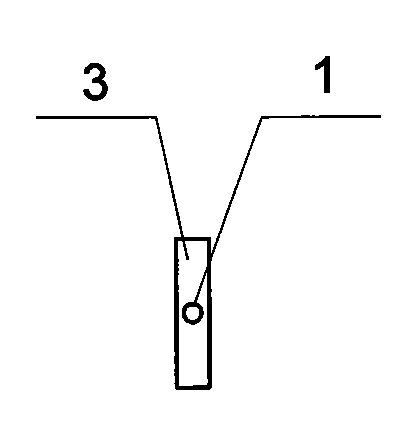

[0013] Specific implementation mode one: the following combination figure 1 , figure 2 and image 3 Describe this embodiment, this embodiment comprises chirped grating 1, positive magnetostrictive film 2, negative magnetostrictive film 3, spiral tube 4 and DC power supply 5,

[0014] The chirped grating 1 is coated with a positive magnetostrictive film 2 and a negative magnetostrictive film 3, the positive magnetostrictive film 2 and the negative magnetostrictive film 3 are pentahedrons whose cross section is an isosceles triangle, and the positive magnetostrictive film 2 and the negative magnetostrictive film 3 are mirrored along the vertical line 7 of the axis of the chirped grating 1, and the symmetry line of the positive magnetostrictive film 2 and the symmetry line of the negative magnetostrictive film 3 are all aligned with the axis of the chirped grating 1 coincide, the apex of the positive magnetostrictive film 2, the apex of the negative magnetostrictive film 3 and...

specific Embodiment approach 2

[0026] Specific embodiment two: The difference between this embodiment and embodiment one is that the material of the positive magnetostrictive film 2 is selected with a magnetostriction coefficient of 300×10 -6 TbFe 2 , the material of the negative magnetostrictive film 3 is selected with a magnetostrictive coefficient of -300×10 -6 SmFe 2 , the other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the chirped grating 1 adopts a high-reflectivity grating with a reflectivity above 95%, and other components and connections are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com