Regeneration method of methyl nitrite

A methyl nitrite and reactor technology, applied in nitrite preparation, chemical recovery, organic chemistry and other directions, can solve the problems of complex process, poor economy, poor operation safety, etc., to simplify the subsequent process, reduce equipment investment, The effect of increasing the regeneration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

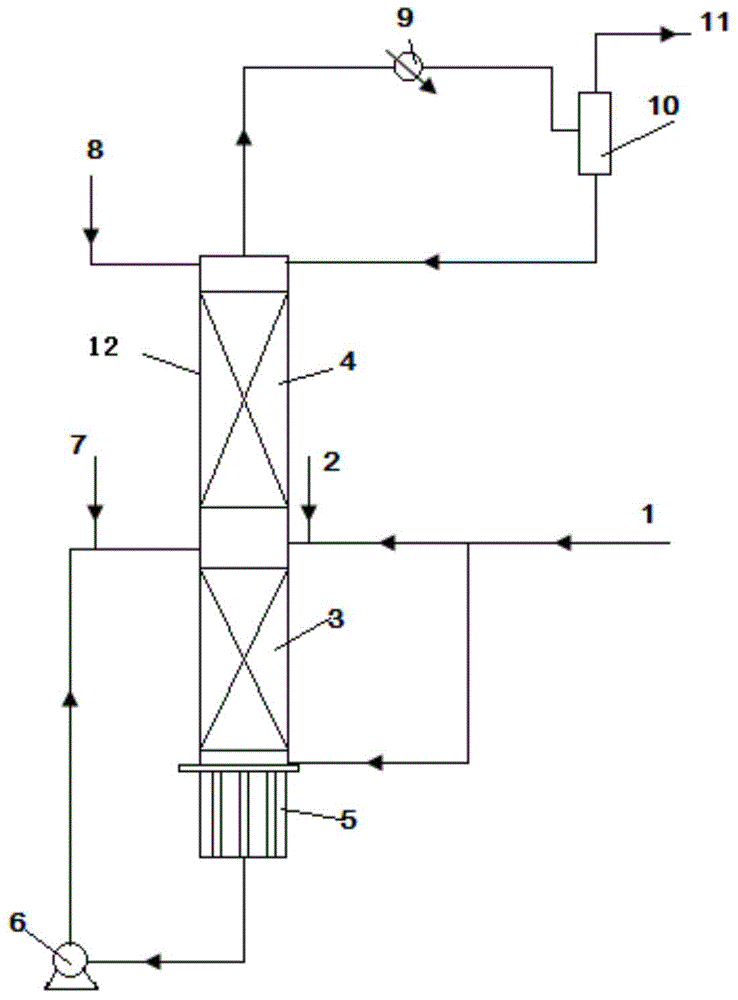

[0045] The circulating gas 1 containing nitric oxide, whose specific composition (volume percentage) is 12% nitric oxide, 2% methyl nitrite, 8% methanol, 12% carbon monoxide and 66% nitrogen, enters the regeneration reactor 12 in two streams, The regeneration reactor 12 has a pressure of 0.5Mpa, and a stream accounting for 20% (volume percentage) of the total gas volume enters the lower section 3 of the regeneration reactor 12 from the bottom of the tower, reacts with nitric acid in the lower section 3 to generate nitrogen dioxide and rises to the upper section 4, and the remaining 80% (percentage by volume) enters the upper section 4 of the regeneration reactor 12 from the middle, and supplementary oxygen 2 is added to the circulating gas in the middle of the regeneration reactor, and fresh methanol 8 is sprayed on the top of the tower. In the upper section 4, nitric oxide and oxygen , methanol reaction regeneration methyl nitrite, the obtained gas containing methyl nitrite is...

Embodiment 2

[0050] The circulating gas 1 containing nitric oxide, whose specific composition (volume percentage) is 5% nitric oxide, 5% methyl nitrite, 7% methanol, 17% carbon monoxide and 66% nitrogen, enters the regeneration reactor 12 in two streams, The regeneration reactor 12 pressure is 0.40Mpa, accounts for 25% (volume percent) of the total gas volume and enters the lower section 3 of the regeneration reactor 12 from the bottom of the tower, reacts with nitric acid in the lower section 3 to generate nitrogen dioxide and rises to the upper section 4, and the remaining 75% (percentage by volume) enters the upper section 4 of the regeneration reactor 12 from the middle, and the supplementary oxygen 2 is added into the recycle gas in the middle of the regeneration reactor 12, and fresh methanol 8 is sprayed on the top of the tower. In the upper section 4, nitric oxide and Oxygen and methanol react to regenerate methyl nitrite, and the obtained gas containing methyl nitrite is discharged...

Embodiment 3

[0055] The circulating gas 1 containing nitric oxide, whose specific composition (volume percentage) is 15% nitric oxide, 1% methyl nitrite, 12% methanol, 15% carbon monoxide and 57% nitrogen, enters the regeneration reactor 12 in two streams, The regeneration reactor 12 has a pressure of 0.35Mpa, and one stream accounting for 5% (volume percentage) of the total gas volume enters the lower section 3 of the regeneration reactor 12 from the bottom of the tower, reacts with nitric acid in the lower section 3 to generate nitrogen dioxide and rises to the upper section 4, and the remaining 95% (percentage by volume) enters the upper section 4 of the regeneration reactor 12 from the middle, and the supplementary oxygen 2 is added into the recycle gas in the middle of the regeneration reactor 12, and fresh methanol 8 is sprayed on the top of the tower. In the upper section 4, nitric oxide and Oxygen and methanol react to regenerate methyl nitrite, and the obtained gas containing methy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com