Method for preparing natural gas by biomass material thermal cracking and thermal cracking furnace used by same

A pyrolysis and biomass technology, applied in the energy field, can solve the problems affecting the efficiency of pyrolysis and the release of calorific value, and achieve the effect of multi calorific value and reduced structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

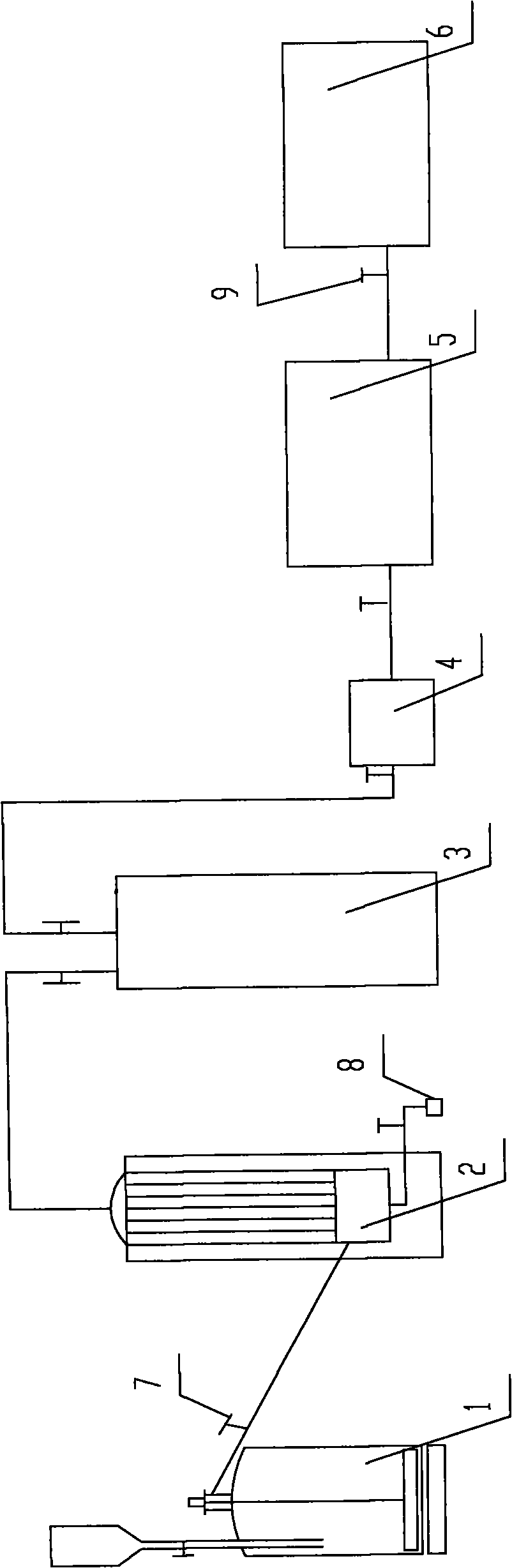

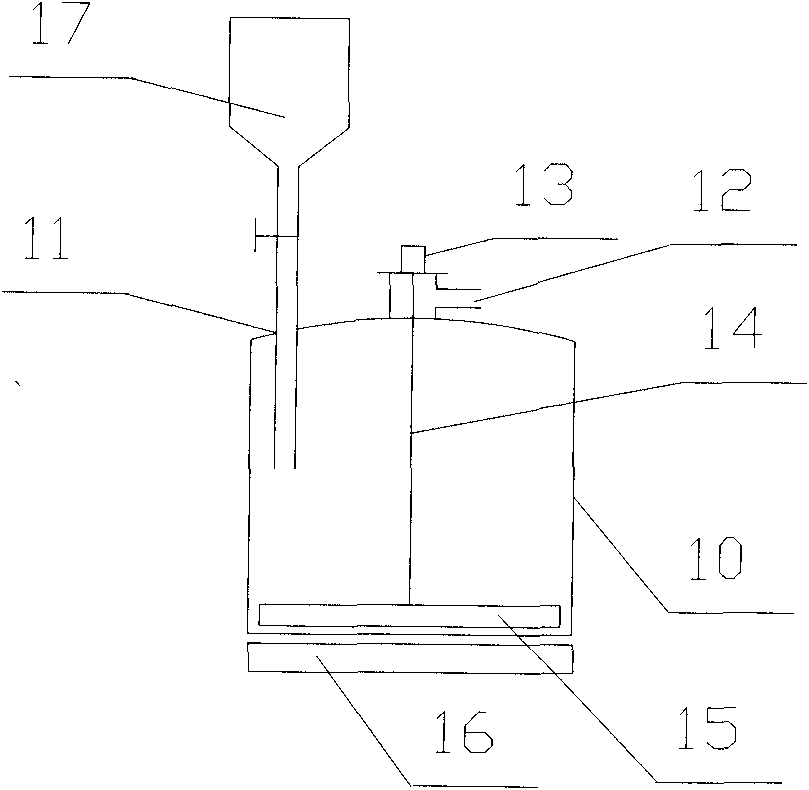

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

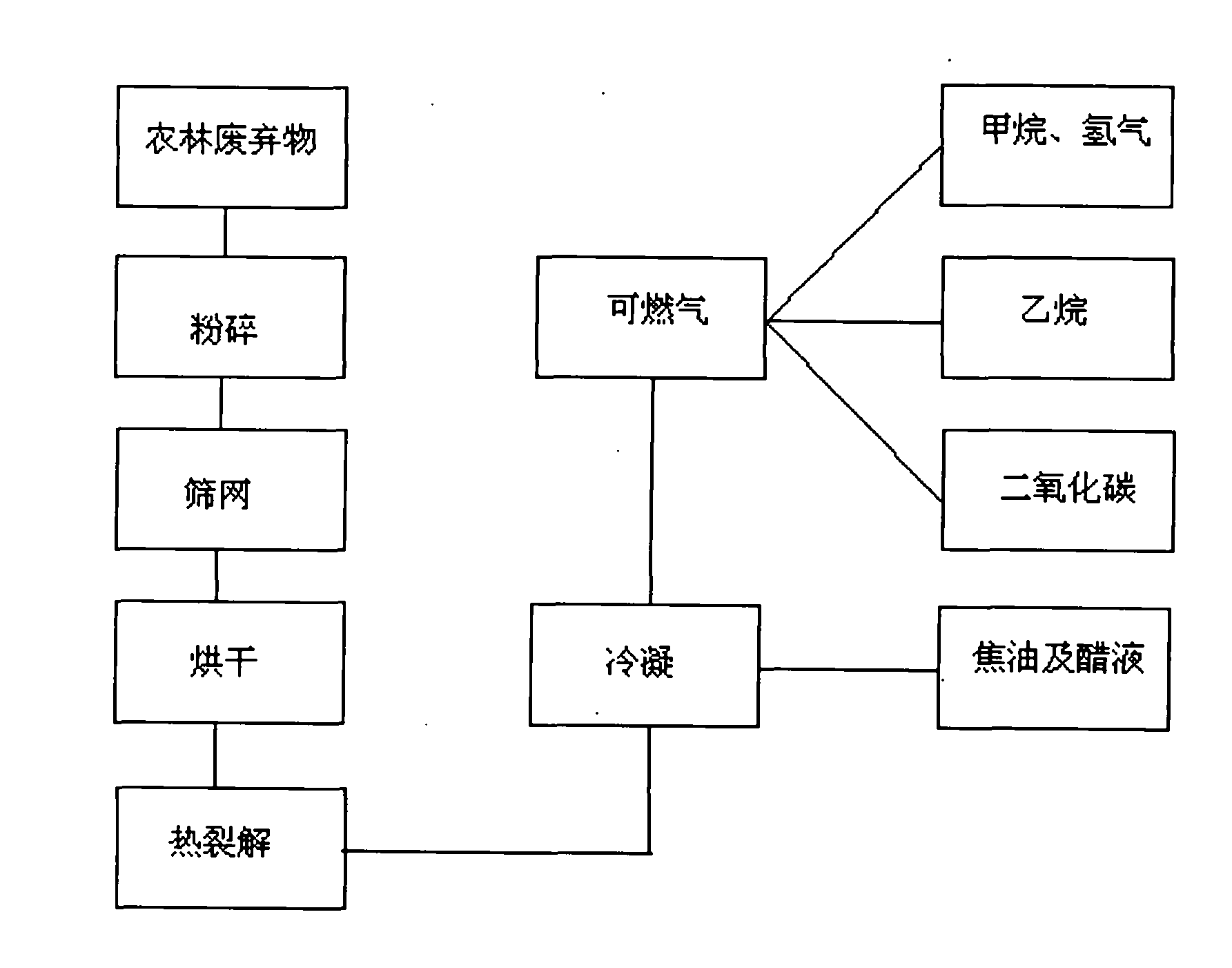

[0028] Depend on figure 1 with figure 2 As shown, the method for preparing natural gas by pyrolysis of biomass material comprises the following steps:

[0029] (1) Material crushing - make the material reach the required particle size by crushing. If the size requirement cannot be reached after several crushings, you can use a screen to filter out larger particles to achieve the required size; but if The particles themselves are small and uniform in size, so there is no need to crush them, such as rice husks, sawdust, etc.

[0030] (2) Drying of materials——by drying, the moisture content of the materials is kept at 0-12%, and the optimal water content is 0-7%, which can greatly reduce the water vapor produced in the thermal cracking step, and is not only beneficial to shorten the The subsequent cooling time also increases the puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com