Refining method of difluprednate

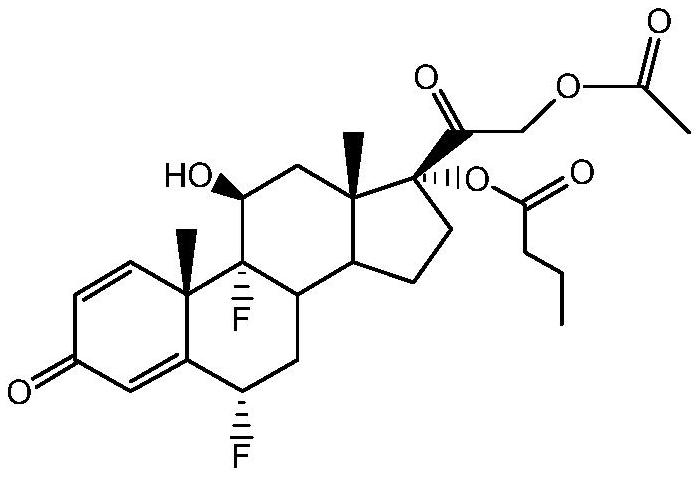

A technology of difluprednate and refining method, applied in the directions of steroids, organic chemistry, etc., can solve problems such as increasing processing cost, and achieve the effects of improving product quality, reducing the number of refining times, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

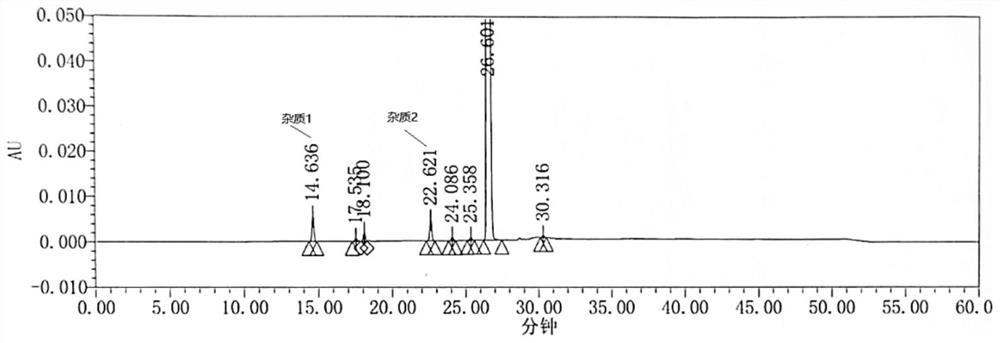

Embodiment 1

[0053] Add 20 g of the dry crude product of difluprednate and 100 mL of dichloromethane into a dry and clean reaction flask, stir and heat up to 30°C to completely dissolve the dry product of crude difluprednate; after dissolving, add 1 g to the system activated carbon, and refluxed at 37 °C for 1 h for decolorization, and then at 35 °C for insulation filtration to obtain the decolorized difluprednate dichloromethane solution; decolorize the decolorized difluprednate dichloromethane solution. Pressure distillation, control the distillation temperature to be about 25 ° C, the vacuum degree is -0.07 MPa, and vacuum distillation to a solution volume of about 30 mL, then add 80 mL of methanol to the concentrated difluprednate dichloromethane solution, and control the distillation temperature. About 50 ℃, the vacuum degree is -0.07MPa, when the solution volume is about 50mL by vacuum distillation, then 120mL petroleum ether is added to the concentrated difluprednate dichloromethane ...

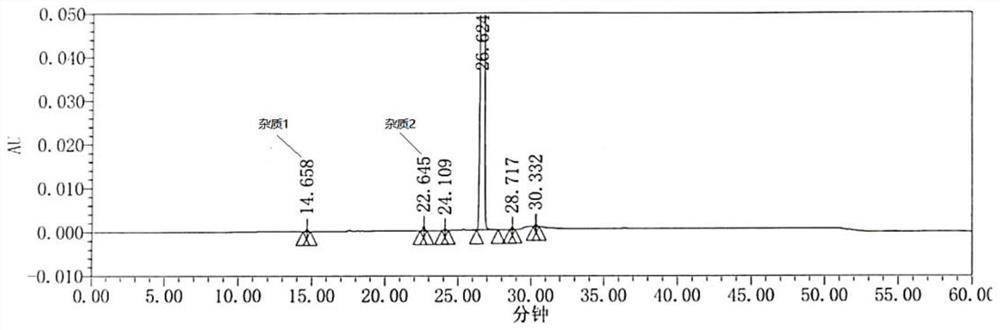

Embodiment 2

[0056] Add 20 g of the dry crude product of difluprednate and 100 mL of dichloromethane into a dry and clean reaction flask, stir and heat up to 30 °C to completely dissolve the dry product of crude difluprednate; after dissolving, add 2 g of 2 g to the system activated carbon, and refluxed at 35 °C for 1 h for decolorization, and then at 35 °C for insulation filtration to obtain a decolorized difluprednate dichloromethane solution; decolorize the decolorized difluprednate dichloromethane solution. Pressure distillation, control the distillation temperature to be about 30 ° C, the vacuum degree is -0.08 MPa, and vacuum distillation to a solution volume of about 30 mL, then add 100 mL of methanol to the concentrated difluprednate dichloromethane solution, and control the distillation temperature. About 45 ℃, the vacuum degree is -0.08MPa, when the solution volume is about 60mL by vacuum distillation, then 130mL petroleum ether is added to the concentrated difluprednate dichlorom...

Embodiment 3

[0059] Add 20 g of the dry crude product of difluprednate and 120 mL of dichloromethane into a dry and clean reaction flask, stir and heat up to 25°C to completely dissolve the crude product of difluprednate; after dissolving, add 1 g of activated carbon, and refluxed at 40 °C for 0.5 h for decolorization, and then filtered at 40 °C to obtain the decolorized difluprednate dichloromethane solution; the decolorized difluprednate dichloromethane solution was subjected to Under reduced pressure distillation, control the distillation temperature to be about 35 ° C, the vacuum degree is -0.06MPa, when the vacuum distillation is carried out to the solution volume of about 35 mL, then add 90 mL of methanol to the concentrated difluprednate dichloromethane solution, and control the distillation The temperature is about 50°C, the degree of vacuum is -0.06MPa, and the solution is distilled under reduced pressure to a volume of about 50mL, then 130mL of petroleum ether is added to the conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com