Hydroxypropyl methylcellulose hollow capsule and production process thereof

A technology of hypromellose and hollow capsules, applied in the direction of capsule transportation, etc., can solve the problems of large water content differences and low water content of plant fibers, and achieve low water content, good safety, and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: transparent colorless hypromellose hollow capsule

[0061] Measured to produce 1000 capsules, fully transparent capsules, no pigment and titanium dioxide mother liquor are required in the raw materials.

[0062] Take 500g of warm purified water, add 120g of HPMC to it, stir while adding, heat the purified water to raise the temperature to 90°C, keep stirring to make the HPMC evenly dispersed, after the HPMC dissolves, lower the temperature to 50°C, and let it stand 12 hours, set aside.

[0063] Take 130g of warm water, add sodium lauryl sulfate until dissolved, add carrageenan, stir while adding, and heat to 50°C.

[0064] There is HPMC raw liquid water in the reaction pot which has been left to stand for 12 hours, add carrageenan to it, raise the temperature of the reaction pot to 60°C, stir for 30 minutes, measure the parameters, stand for 1 hour, and set aside.

[0065] Pour the pre-prepared auxiliary solution, that is, the solution containing sodium ...

Embodiment 2

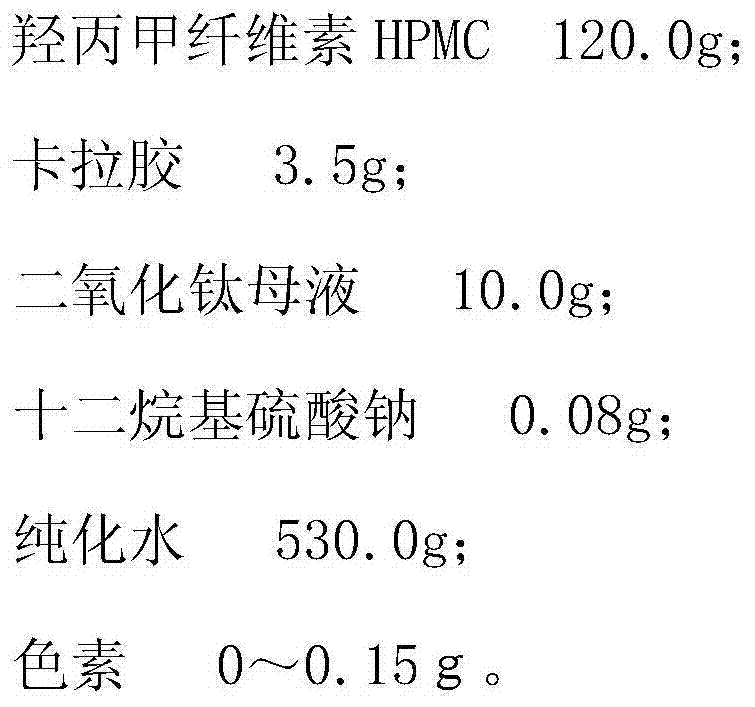

[0067] Embodiment 2: white and red hypromellose hollow capsules

[0068] Measured to produce 1000 capsules.

[0069] Weigh TiO 2 10g, prepare purified water 100g, will TiO 2 Add water into the grinder, keep the temperature of the grinder at 40°C, set the speed of the grinder to 800 rpm, and grind for 20 minutes. Filter the ground powder with a 250-mesh silk bag, then add purified water at 80°C to prepare Titanium dioxide mother liquor, total liquor is 110g.

[0070] Take 500g of warm purified water, add 120g of HPMC to it, stir while adding, heat the purified water to raise the temperature to 90°C, keep stirring to make the HPMC evenly dispersed, after the HPMC dissolves, lower the temperature to 50°C, and let it stand 12 hours, set aside.

[0071] Take 130g of warm water, add sodium lauryl sulfate until dissolved, add carrageenan, stir while adding, and heat to 50°C.

[0072] There is HPMC raw liquid water in the reaction pot which has been left to stand for 12 hours, ad...

Embodiment 3

[0077] Embodiment 3: all red hypromellose hollow capsules

[0078]The process equipment and raw material composition used are basically the same as in Example 2, the only difference is that the raw material pigment carmine is 0.128g, and the pigment solution and titanium dioxide mother liquor 10g are added to the glue solution together.

[0079] The hollow capsule prepared in this embodiment can be completely disintegrated within 10 minutes of gastric dissolution, and is resistant to high temperature, high humidity and cold.

[0080] Working process of the present invention:

[0081] A kind of hypromellose hollow capsule of the present invention and production process are in the working process, through the proportioning of hypromellose, surfactant, coagulation aid i.e. sodium lauryl sulfate, carrageenan, preparation process Hypromellose hollow capsules are produced by adopting high-temperature mixing and high-temperature drying technology, which is opposite to the low-temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com