Lactobacillus casei SITCC No.10009

A technology of Lactobacillus casei and strains, which is applied in the field of microorganisms, can solve the problems that the content of butanedione cannot reach the ideal and the like, and achieves the effects of high production capacity of butanedione, increasing species and increasing yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A kind of Lactobacillus casei (Lactobacillus casei) SITCC No. 10009 collection and separation, the steps are as follows:

[0068] (1) Sample collection

[0069] Sampling from natural fermented fruit and vegetable products, traditional fermented dairy products (milk fans, milk cakes, yogurt, kefir, etc.), raw milk, dough, kefir grains (Tibetan mushroom), silage, etc. Put the collected samples in an ice box and refrigerate them, keep them at a lower temperature and bring them back to the laboratory and place them in a refrigerator at 4°C to separate the lactic acid bacteria as soon as possible;

[0070] (2) Sample pretreatment

[0071] Take 10g of solid sample (10mL of liquid sample) and put it into a 250mL Erlenmeyer flask (containing glass beads) filled with 90mL of sterile water, shake it and let it stand for 20 minutes for use;

[0072] (3) Separation of lactic acid bacteria strains

[0073] Calculate at a volume ratio of 1:10. Use sterile water to serially dilute the above-men...

Embodiment 2

[0090] The SITCC No. 10009 strain of Example 1 was subjected to microbiological identification

[0091] (1) Colony characteristics

[0092] The SITCC No.10009 strain was streaked on the MRS plate and cultured anaerobic at 37°C for 48h. The SITCC No.10009 strain grew well. The colony was round, raised, and neatly edged. The color was milky white and slightly yellowish, opaque, and the surface Moist and smooth, can be drawn when picked;

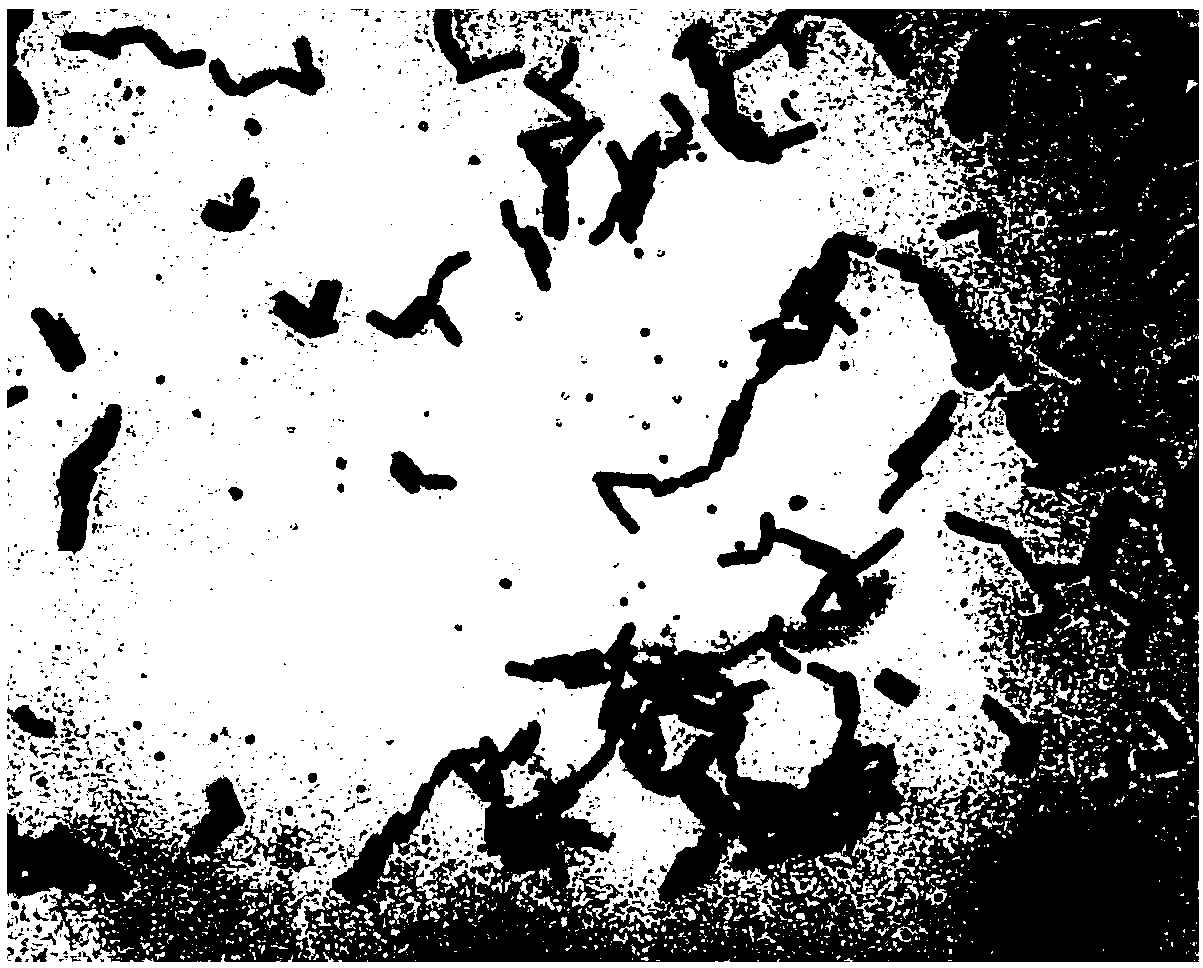

[0093] (2) Morphological characteristics of bacteria

[0094] The Gram staining method (Zhou Deqing. Microbiology Tutorial[J].2011.) was used to observe the SITCCNo.10009 bacterial cells obtained in step (1) by Gram staining, and the results are shown in figure 1 Shown from figure 1 It can be seen that the bacteria are in the form of non-moving rods, mostly arranged in chains with different lengths, and there are also individual scattered arrangements. The size of the bacteria is generally 0.6μm×1.5μm, without spores, and Gram staining is positive;

[0...

Embodiment 3

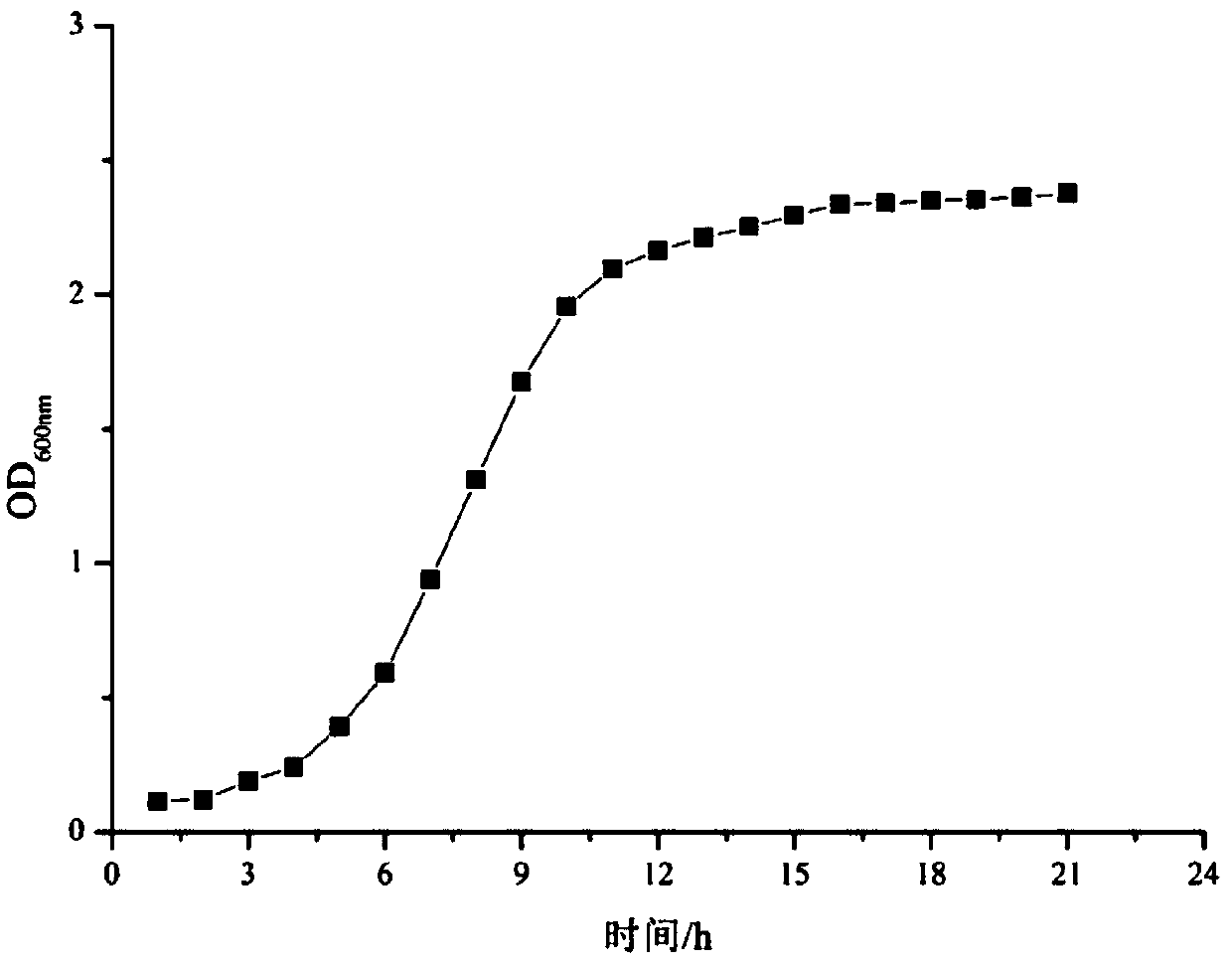

[0108] Growth characteristics of Lactobacillus casei SITCC No. 10009

[0109] (1), Lactobacillus casei (Lactobacillus casei) SITCC No.10009 strain growth curve drawing. The activated Lactobacillus casei (Lactobacillus casei) SITCC No.10009 is inserted into the MRS liquid medium at 2% (v / v) inoculum Incubate at 37°C for 16 hours, measure the OD value of the culture solution at 600 nm every 1-2 hours, and plot the OD value against time to obtain the growth curve of Lactobacillus casei SITCC No. 10009 in MRS. The result Such as figure 2 Shown from figure 2 It can be seen that Lactobacillus casei (Lactobacillus casei) SITCC No.10009 grows rapidly in MRS medium, entering the logarithmic phase at about 3h, and entering the stable phase at about 12h;

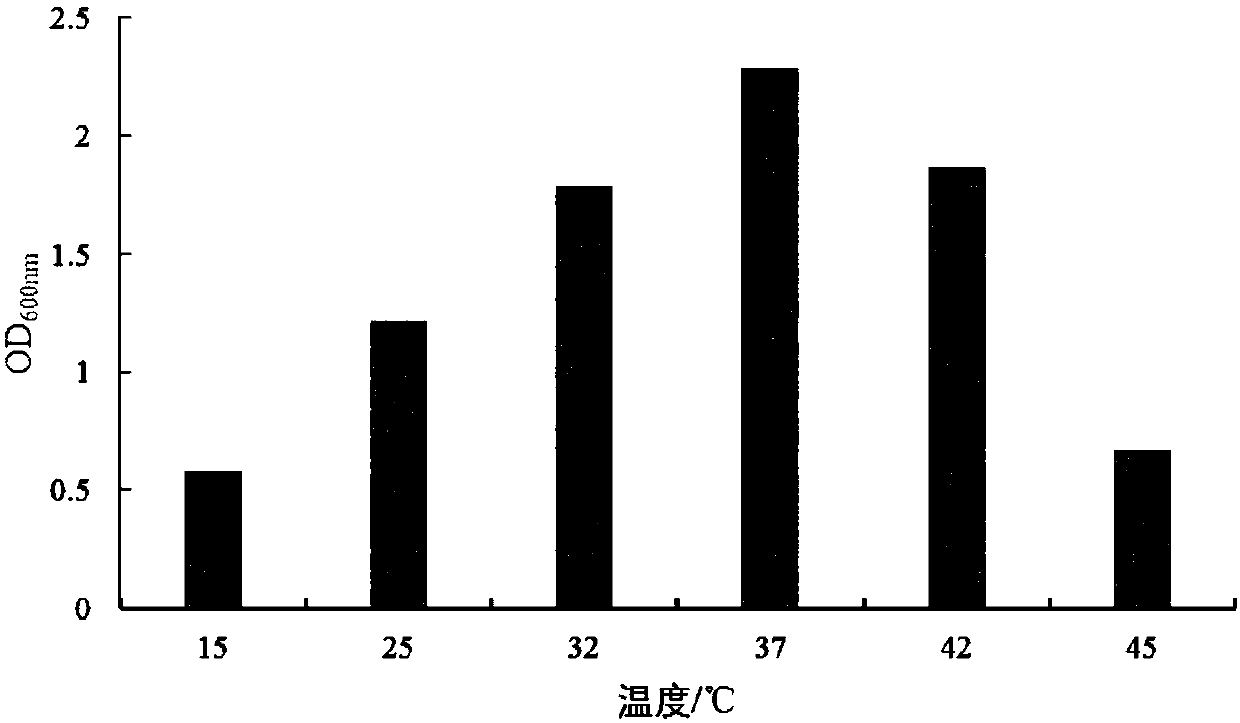

[0110] (2) Determination of the optimum growth temperature of Lactobacillus casei SITCC No. 10009. The activated Lactobacillus casei SITCC No. 10009 is inoculated into 10 mL MRS at 2% (v / v) inoculation amount. In the liquid medium, cultu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com