Method for removing impurity boron of metallurgical silicon by high-basicity refining agent

A technology of metallurgical grade silicon and refining agent, applied in the field of solar photovoltaic, can solve the problems of reducing the application requirements of solar cells, difficult boron content, etc., and achieve the effects of easy industrialization and application, good boron removal effect, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

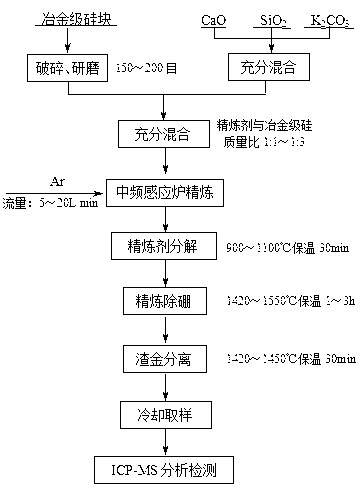

[0021] (1) Crush metallurgical-grade silicon with a boron content of 10ppmw into 30g of powder with a particle size of 150-200 mesh, and then mix 60g of high-alkalinity refining agent and metallurgical-grade silicon powder at a ratio of 2:1 to fully evenly, among which high The alkalinity refining agent is analytically pure CaO with a mass content of 50%, and analytically pure SiO with a mass content of 50%. 2 mixed powder;

[0022] (2) Put the mixed material obtained in step (1) into a graphite crucible with a silicon nitride coating on the inner wall, place the crucible in a quartz tube in an intermediate frequency induction furnace, and feed a flow rate of 15L / Min of argon protection, and use 50 ℃ / min to raise the temperature to 900 ℃, and then keep it for 30 minutes; Ensure that the liquid silicon melt is fully separated from the solid refining agent; finally cool down to room temperature at 50°C / min, then turn off the argon gas, and take out the sample;

[0023] (3) Us...

Embodiment 2

[0025] (1) Crush metallurgical-grade silicon with a boron content of 15ppmw into 30g of powder with a particle size of 150-200 mesh, and then mix 30g of high-alkalinity refining agent and metallurgical-grade silicon powder at a ratio of 1:1 to fully evenly, among which high The alkalinity refining agent is analytically pure CaO with a mass content of 40%, and analytically pure SiO with a mass content of 40%. 2 , 20% analytically pure K 2 CO 3 mixed powder;

[0026] (2) Put the mixed material obtained in step (1) into a graphite crucible with a silicon nitride coating on the inner wall, place the crucible in a quartz tube in an intermediate frequency induction furnace, and feed a flow rate of 20L / Min of argon protection, and use 50 ℃ / min to heat up to 1000 ℃, keep warm for 30 minutes to ensure that the K in the refining agent 2 CO 3 Fully decompose, metallurgical grade silicon is still solid at this time; then heat up to 1550°C at 15°C / min and hold for 2 hours, then cool d...

Embodiment 3

[0029] (1) Crush the bulk metallurgical grade silicon with a boron content of 22ppmw to 30g of powder with a particle size of 150-200 mesh, and then mix 90g of high alkalinity refining agent and metallurgical grade silicon powder at a ratio of 3:1 to fully evenly, among which the high The alkalinity refining agent is analytically pure CaO with a mass content of 40%, and analytically pure SiO with a mass content of 40%. 2 , 20% analytically pure K 2 CO 3 mixed powder;

[0030] (2) Put the mixed material obtained in step (1) into a graphite crucible with a silicon nitride coating on the inner wall, place the crucible in a quartz tube in an intermediate frequency induction furnace, and feed a flow rate of 15L / Min of argon protection, and use 50 ℃ / min to heat up to 1100 ℃, keep warm for 30 minutes to ensure that the K in the refining agent 2 CO 3 Fully decompose, metallurgical grade silicon is still solid at this time; then heat up to 1500°C at 15°C / min and hold for 3 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com