Method of preparing hierarchical pore ceramsite from red mud and coal ash

A technology of fly ash and multi-level pores is applied in the field of solid waste recycling and environment, which can solve the problems of low removal efficiency of pollutants in water, less than 15% utilization rate, limited application scope, etc. Environmental hazard, effect of improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: a kind of method utilizing red mud and fly ash to prepare multi-level porous ceramsite, concrete steps are as follows:

[0031] (1) Mix fly ash and red mud evenly to obtain mixture A; dry and pulverize agricultural and forestry waste slag (bagasse) to obtain agricultural and forestry waste granules; mix mixture A and agricultural and forestry waste granules evenly, add water and stir evenly to obtain mixed mud B; wherein in mass percentage, fly ash accounts for 75% in the mixture A; the mass ratio of agricultural and forestry waste slag particles to the mixture A is 18:100;

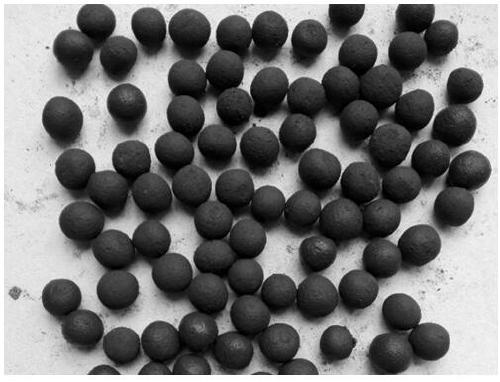

[0032] (2) Granulate the mixed mud B in step (1) to obtain ceramsite blank sample C (see figure 1 ); wherein the particle size of ceramsite blank sample C is 10mm;

[0033] (3) The ceramsite blank sample C in step (2) was treated at a temperature of 110°C for 90 minutes, and then placed at a temperature of 450°C for 30 minutes at a constant temperature to obtain prefabricated ceramsi...

Embodiment 2

[0043] Embodiment 2: a kind of method utilizing red mud and fly ash to prepare multi-level porous ceramsite, concrete steps are as follows:

[0044] (1) Mix fly ash and red mud evenly to obtain mixture A; dry and pulverize agricultural and forestry waste residue (sawdust) to obtain agricultural and forestry waste residue particles; mix mixture A and agricultural and forestry waste residue particles evenly, add water and stir evenly to obtain mixed mud B ; Wherein by mass percentage, fly ash accounts for 71.4% in the mixture A; the mass ratio of agricultural and forestry waste slag particles and mixture A is 14:100;

[0045](2) Granulating the mixed mud B in step (1) to obtain ceramsite blank sample C; wherein the particle size of ceramsite blank sample C is 10mm;

[0046] (3) Treat the ceramsite blank sample C in step (2) at a temperature of 105°C for 110 minutes, and then place it at a temperature of 400°C for 40 minutes to obtain prefabricated ceramsite;

[0047] (4) The pr...

Embodiment 3

[0054] Embodiment 3: a kind of method utilizing red mud and fly ash to prepare multi-level porous ceramsite, concrete steps are as follows:

[0055] (1) Mix fly ash and red mud evenly to obtain mixture A; dry and pulverize agricultural and forestry waste residue (coffee grounds) to obtain agricultural and forestry waste residue particles; mix mixture A with agricultural and forestry waste residue particles evenly, add water and stir evenly to obtain mixed mud B; wherein in mass percentage, fly ash accounts for 84.7% in mixture A; the mass ratio of agricultural and forestry waste residue particles to mixture A is 14.4:100;

[0056] (2) Granulating the mixed mud B in step (1) to obtain ceramsite blank sample C; wherein the particle size of ceramsite blank sample C is 15mm;

[0057] (3) Treat the ceramsite blank sample C in step (2) at a temperature of 100°C for 130 minutes, and then place it at a temperature of 350°C for 60 minutes at a constant temperature to obtain prefabricat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com