Novel preparation method of high-performance composite film

A composite membrane, high-performance technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of reduced mechanical properties of membrane materials, a large amount of organic solvents, and difficulty in scraping and coating to form molds. Simple equipment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 3g of fully dried polyvinylidene fluoride to 92g of dimethylacetamide, stir and dissolve at 50°C for 2 hours, add 5g of anhydrous lithium chloride after the polymer is completely dissolved, and continue stirring until completely Dissolve to obtain a homogeneous solution, let it stand for degassing for 30 minutes, and set aside;

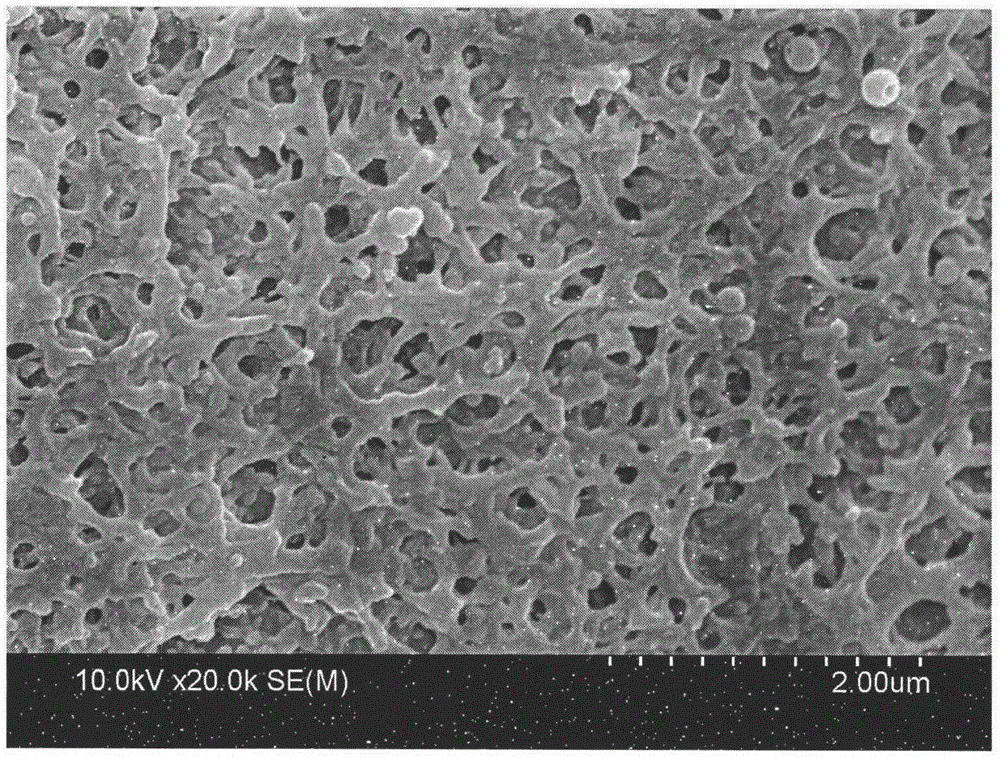

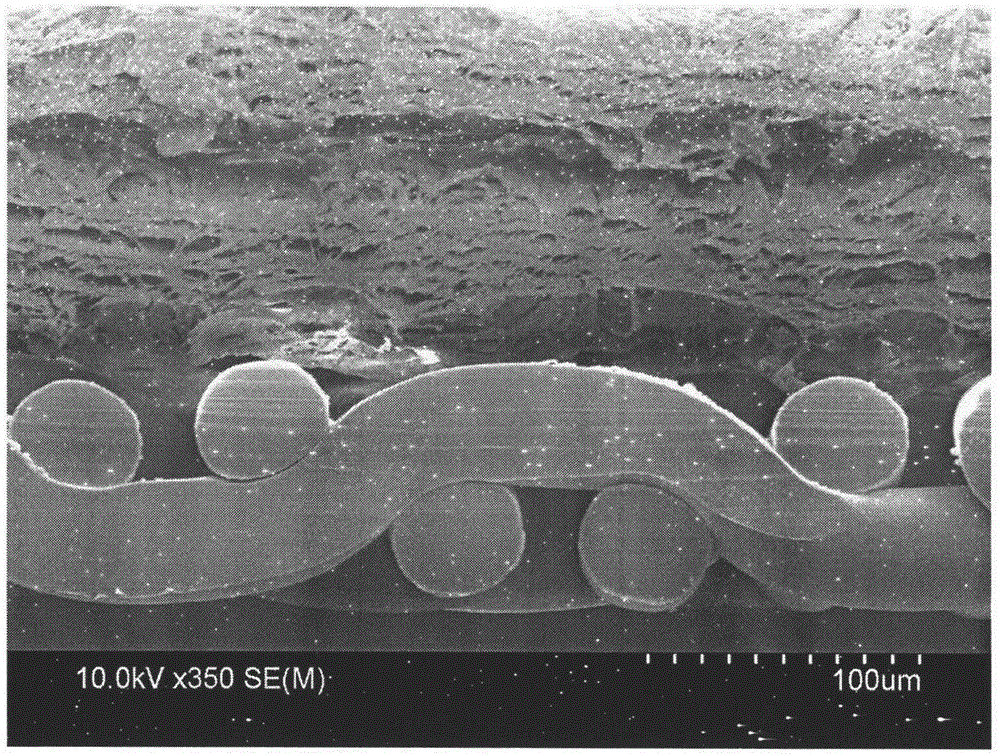

[0022] (2) The solution after the defoaming obtained in step (1) is placed in a constant pressure propeller, and the propulsion speed is set as 100mL / h, and the method of solution injection is adopted, and the spray distance is adjusted to be 5cm, and the rotating speed of the roll is 10r / min , The feed temperature is 25°C, the atomization pressure is 1.5MPa, and the air flow rate is 160mL / h, the casting solution is sprayed on the polyester nonwoven fabric fixed on the surface of the roller, and the roller is rotated while the solution is sprayed. The lower half was submerged in tap water in a coagulation bath for 10 hours, then transfe...

Embodiment 2

[0025] (1) Add 10g of fully dried polyvinylidene fluoride to 85g of dimethylacetamide, stir and dissolve at 80°C for 3 hours, add 5g of anhydrous lithium chloride after the polymer is completely dissolved, and continue stirring until completely Dissolve to obtain a homogeneous solution, let stand for degassing for 5 hours, and set aside;

[0026] (2) The solution after the defoaming obtained in step (1) is placed in a constant pressure propeller, and the propulsion speed is set to 400mL / h, and the solution is sprayed, and the spray distance is adjusted to be 10cm, and the rotating speed of the roll is 15r / min , The feed temperature is 50°C, the atomization pressure is 2.5MPa, the air flow rate is 200mL / h, the casting solution is sprayed on the polypropylene nonwoven fabric fixed on the surface of the roller, and the roller is rotated while the solution is sprayed. Submerge the lower part in the tap water of the coagulation bath. After the spraying is completed, take off the no...

Embodiment 3

[0029] (1) Add 10g of bisphenol A polysulfone to 85g of nitrogen methylpyrrolidone, stir and dissolve at 80°C for 3 hours, add 5g of calcium chloride after the polymer is completely dissolved, and continue to stir until it is completely dissolved to obtain homogeneous phase solution, defoamed in a vacuum oven for 1h, and set aside;

[0030] (2) The solution after the defoaming obtained in step (1) is placed in a constant pressure propeller, and the propulsion speed is set as 300mL / h, and the method of solution injection is adopted, and the spraying distance is adjusted to be 15cm, and the rotating speed of the rotating roller is 30r / min , The feed temperature is 50°C, the atomization pressure is 1.5MPa, the air flow rate is 140mL / h, the casting solution is sprayed on the polyester nonwoven fabric fixed on the surface of the roller, and the roller is rotated while the solution is sprayed. Immerse the lower half in the coagulation bath absolute ethanol. After the spraying is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com