A method of preparing porous carbon by adopting spherical zinc oxide as a template and applications of the porous carbon

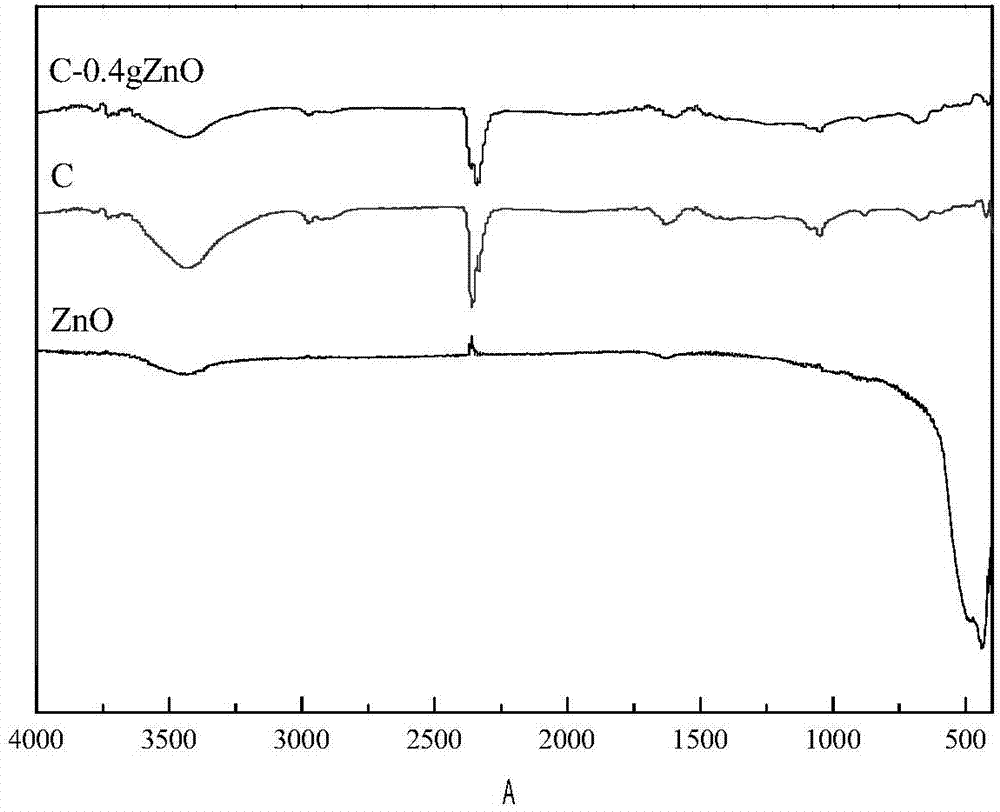

A technology of zinc oxide and porous carbon, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, and other chemical processes, can solve problems such as pollution and achieve the effect of reducing environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

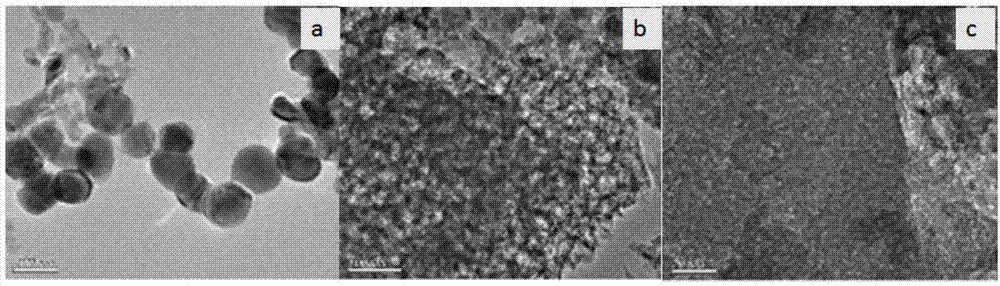

[0025] (1) Preparation of spherical zinc oxide:

[0026] Dissolve citric acid, zinc nitrate and ethylene glycol in deionized water at a molar ratio of 3:1:5, stir for 1 hour, put it in a drying oven at 80°C for 8 hours, then dry it at 130°C for 2 hours, put it in a muffle furnace for sintering , the sintering temperature is 600°C, take it out after 4h, and then naturally cool to room temperature to obtain spherical zinc oxide.

[0027] (2) Preparation of solution A: Fully dissolve phenolic resin and F127 with a mass ratio of 1:1 into absolute ethanol, stir in a water bath stirrer at a constant temperature of 30°C for 6 hours until fully dissolved, and obtain solution A;

[0028] (3) Preparation of composite solid material: uniformly disperse the spherical zinc oxide prepared in step (1) into the solution A of step (2), continue magnetic stirring at 30° C. for 30 min, then pour the sample into a petri dish, Put it at room temperature until the solution is fully volatilized, dr...

Embodiment 2

[0031] (1) Preparation of spherical zinc oxide:

[0032] Dissolve citric acid, zinc nitrate and ethylene glycol in deionized water at a molar ratio of 3:1:15, stir for 4 hours, put it in a drying oven at 80°C for 24 hours, dry it at 130°C for 10 hours, put it in a muffle furnace for sintering , the sintering temperature is 900°C, take it out after 4 hours, and then cool it down to room temperature naturally to obtain spherical zinc oxide.

[0033] (2) Preparation of solution A: Fully dissolve phenolic resin and F127 with a mass ratio of 1:1 into absolute ethanol, stir in a water bath stirrer at a constant temperature of 65°C for 2 hours until fully dissolved, and obtain solution A;

[0034] (3) Preparation of composite solid material: uniformly disperse the spherical zinc oxide prepared in step (1) into the solution A of step (2), continue to stir magnetically at 65°C for 120 min, then pour the sample into a petri dish, Put it at room temperature until the solution is fully v...

Embodiment 3

[0039] (1) Preparation of spherical zinc oxide:

[0040] Dissolve citric acid, zinc nitrate and ethylene glycol in deionized water at a molar ratio of 3:1:12, stir for 2 hours, put it in a drying oven at 80°C for 12 hours, dry it at 130°C for 7 hours, put it in a muffle furnace for sintering , the sintering temperature is 900°C, take it out after 4 hours, and then cool it down to room temperature naturally to obtain spherical zinc oxide.

[0041] (2) Preparation of solution A: Fully dissolve phenolic resin and F127 with a mass ratio of 1:1 into absolute ethanol, stir in a water bath stirrer at a constant temperature of 50°C for 3 hours until fully dissolved, and obtain solution A;

[0042] (3) Preparation of composite solid material: uniformly disperse the spherical zinc oxide prepared in step (1) into the solution A of step (2), continue magnetic stirring at 50° C. for 30 min, then pour the sample into a petri dish, Put it at room temperature until the solution is fully vola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com