Water-based amino acrylic stoving varnish

A technology of aminoacrylic acid and hydroxyacrylic acid, applied in the direction of coating, etc., can solve the problems of organic solvent emissions, hidden dangers, environmental pollution, etc., and achieve the effects of saving production costs, reducing volatilization, and reducing environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

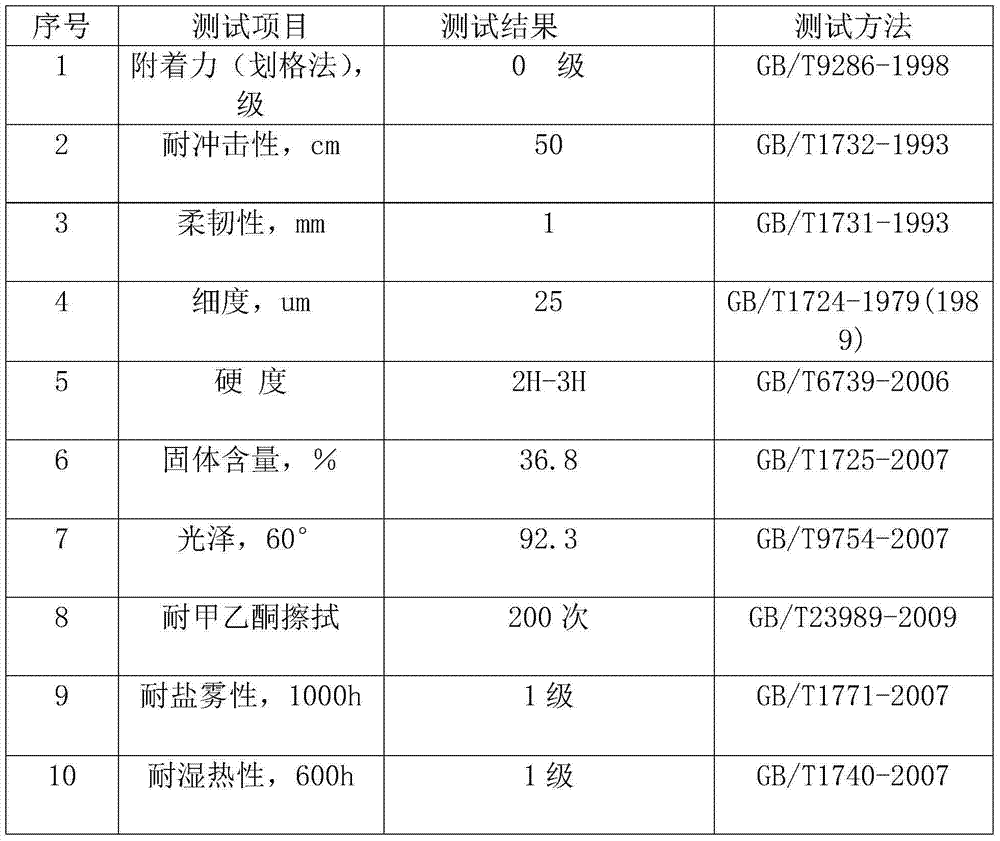

Embodiment 1

[0018] Weigh the following raw materials according to the weight unit: 38 parts by weight of water-based hydroxyacrylic resin, 5 parts by weight of dimethylethanolamine, 45 parts by weight of deionized water, 0.3 parts by weight of defoamer (SN-154), 1.2 parts by weight of dispersant (SN5040) 5.0 parts by weight of high-pigment carbon black, 5.5 parts by weight of amino resin (Cytec CY325).

[0019] First disperse deionized water, dispersant, defoamer, and high-pigment carbon black evenly, and grind them into a sand mill until the fineness is ≤30 microns, then add dimethylethanolamine, add water-based hydroxyacrylic resin and amino resin, and mix The product is then available.

Embodiment 2

[0021] Weigh the following raw materials according to the weight unit: 42.7 parts by weight of water-based hydroxyl acrylic resin, 5.5 parts by weight of dimethylethanolamine, 35 parts by weight of deionized water, 0.5 parts by weight of defoamer (SN‐154), 2.0 parts by weight of dispersant (SN5040) 6.8 parts by weight of high pigment carbon black, 7.5 parts by weight of amino resin (Changchun MR625S high methylated amino resin).

[0022] First disperse deionized water, dispersant, defoamer, and high-pigment carbon black evenly, and grind them into a sand mill until the fineness is ≤30 microns, then add dimethylethanolamine, add water-based hydroxyacrylic resin and amino resin, and mix The product is then available.

Embodiment 3

[0024] Weigh the following raw materials according to the weight unit: 51 parts by weight of water-based hydroxyacrylic resin, 1.5 parts by weight of dimethylethanolamine, 35 parts by weight of deionized water, 0.5 parts by weight of defoamer (SN-154), and 1.5 parts by weight of dispersant (SN5040) 5.0 parts by weight of high-pigment carbon black, 5.5 parts by weight of amino resin (Cytec CY325).

[0025] First disperse deionized water, dispersant, defoamer, and high-pigment carbon black evenly, and grind them into a sand mill until the fineness is ≤30 microns, then add dimethylethanolamine, add water-based hydroxyacrylic resin and amino resin, and mix The product is then available.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com