Municipal sludge treatment and fertilizer preparation system based on pyrohydrolysis-ultrahigh-temperature aerobic fermentation

A municipal sludge and aerobic fermentation technology, which is applied in the field of municipal sludge treatment, can solve the problems of affecting the efficiency of sludge treatment and disposal, the influence of ambient temperature, and the high ratio of material addition, so as to achieve cost reduction, long duration of high temperature, and high fermentation efficiency. The effect of cycle reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

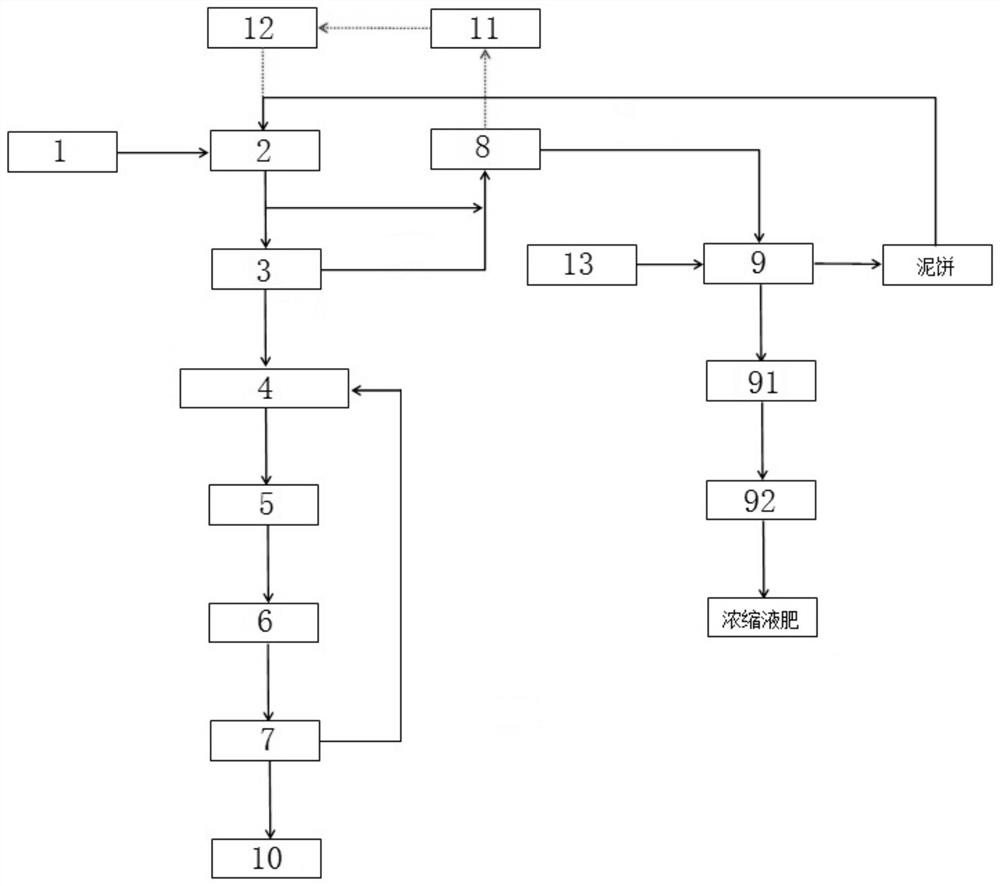

[0052] This embodiment provides a kind of municipal sludge treatment fertilizer system based on thermal hydrolysis-ultra-high temperature aerobic fermentation, such as figure 1 As shown, the municipal sludge treatment fertilizer system includes sequentially connected:

[0053] Pre-dehydration unit 1, thermal hydrolysis unit 2, plate and frame dehydration unit 3, ultra-high temperature aerobic fermentation unit 4, crushing unit 5, extrusion granulation unit 6, screening unit 7;

[0054] Thermal hydrolysis unit 2 is sequentially connected with anaerobic digestion unit 8, centrifugal dehydration unit 9, filtrate treatment unit 91, and concentration unit 92;

[0055] Plate and frame dehydration unit 3 is connected with anaerobic digestion unit 8;

[0056] The hyperthermia aerobic fermentation unit 4 includes a fermenter (not shown).

[0057] It also includes a nutrient soil collection unit 10, which is connected with the screening unit 7.

[0058] Also comprise the methane coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com