Method for improving dewatering performance of dredged sediment

A technology for dredging sediment and dewatering performance, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve flocculant residue, acrylamide poisoning, limit sediment The degree of dehydration and other issues can be reduced to reduce operating costs and improve dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for improving the dewatering performance of dredged sediment, comprising the following steps:

[0028] (1) Take the dredged sediment from a certain section of Dongting Lake, adjust the moisture content of the dredged sediment to 91%, and adjust the pH of the dredged sediment to 6.9;

[0029] (2) The pH value of the dredged bottom mud in step (1) is adjusted to 3.0 with sulfuric acid to obtain acidified dredged bottom mud;

[0030] (3) adding size to the acidified dredged bottom mud in step (2) is 650nm and accounts for the submicron iron of acidified dredged bottom mud dry weight 10%, with the speed mechanical stirring of 330r / min 3min, then with the speed of 120r / min Slow speed mechanical stirring for 8 minutes to obtain iron-containing dredged sediment;

[0031] (4) Add the hydrogen peroxide that accounts for 2.5% of iron-containing dredging bottom mud dry weight to the iron-containing dredging bottom mud in step (3), stir 6~7min with the fast speed of 360r / ...

Embodiment 2

[0034] A method for improving the dewatering performance of dredged sediment, comprising the following steps:

[0035] (1) Take the dredged sediment from a certain section of Dongting Lake, adjust the moisture content of the dredged sediment to 91%, and adjust the pH of the dredged sediment to 6.9;

[0036] (2) Adjusting the pH value of the dredged sediment in step (1) to 3.0 with sulfuric acid, and then filtering and dehydrating the acidified dredged sediment.

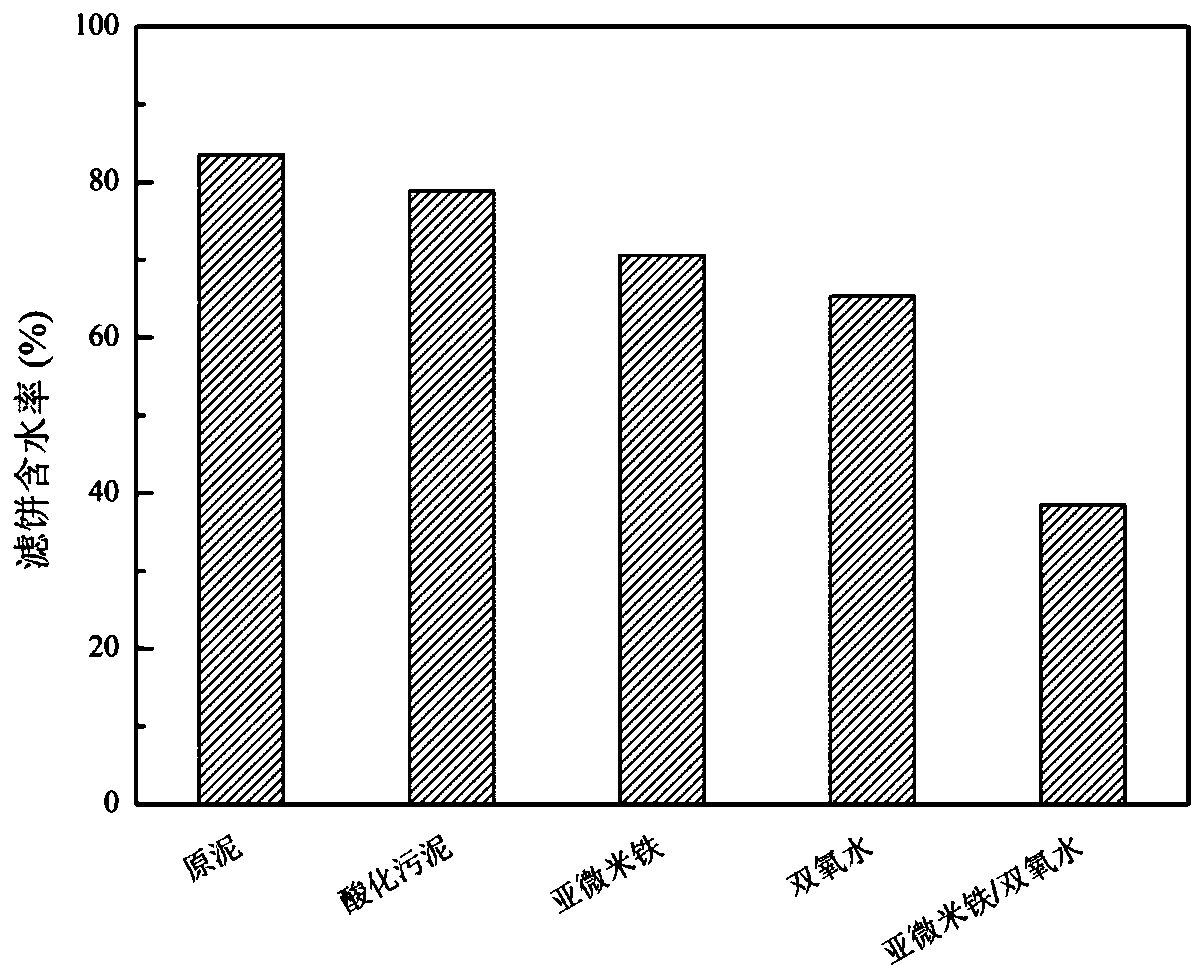

[0037] Detect the dehydration performance of the dredged sediment before and after the treatment, and the results are as follows: the water content of the filter cake after the dewatering of the dredged sediment before the treatment is 85.4%; The moisture content is 78.9%.

Embodiment 3

[0039] A method for improving the dewatering performance of dredged sediment, comprising the following steps:

[0040] (1) Take the dredged sediment from a certain section of Dongting Lake, adjust the moisture content of the dredged sediment to 91%, and adjust the pH of the dredged sediment to 6.9;

[0041] (2) The pH value of the dredged bottom mud in step (1) is adjusted to 3.0 with sulfuric acid to obtain acidified dredged bottom mud;

[0042] (3) adding size to the acidified dredged bottom mud in step (2) is 650nm and accounts for the submicron iron of acidified dredged bottom mud dry weight 10%, with the speed mechanical stirring of 330r / min 3min, then with the speed of 120r / min Stir at a slow speed for 8 minutes, continue to use magnets to recover the remaining submicron iron in the dredged sediment, and then filter and dewater the iron-containing dredged sediment.

[0043] Detect the dehydration performance of the dredged sediment before and after the treatment, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com