Biogas residue thermal cracking solid product and application method thereof

A thermal cracking and biogas residue technology, applied in waste fuel, fermentation, etc., can solve the problems of difficult disposal, high sludge moisture content, limited application, etc., reduce the harm of ammonia nitrogen and organic acid poisoning, and improve anaerobic digestion Efficiency, the effect of improving growth metabolic rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

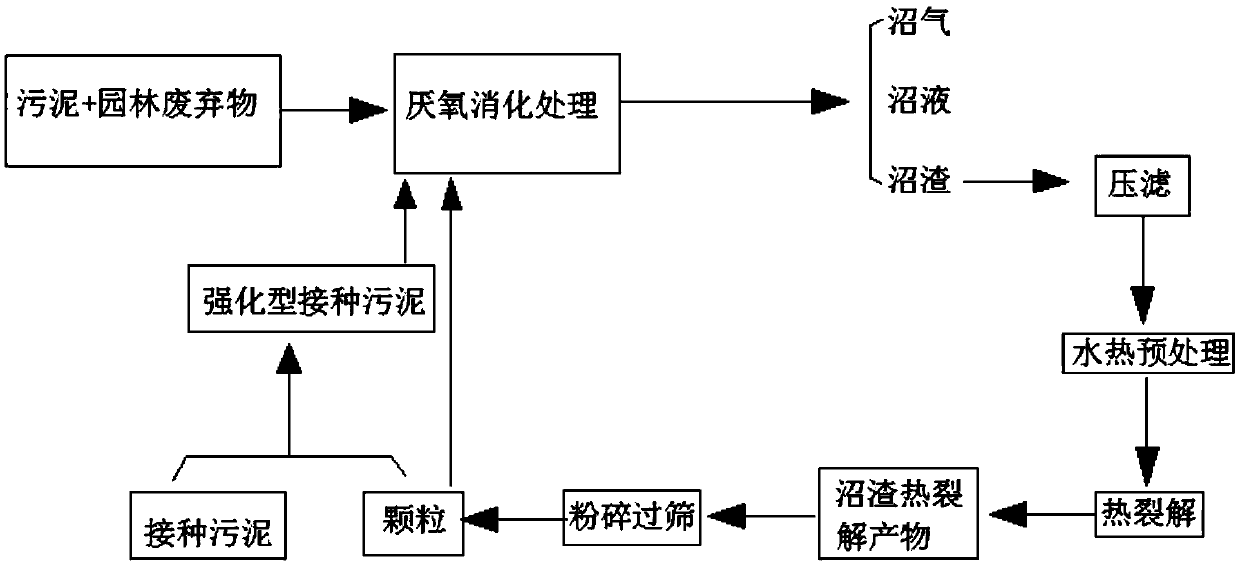

[0036] The sludge obtained from a sewage plant and the collected garden waste (thatched grass) were combined anaerobic digestion at 35°C, and part of the biogas residue produced was dehydrated by pressure filtration. Under hydrothermal conditions (200°C, 1.1MPa, 1 hour) The material precursor is prepared under high temperature, followed by thermal cracking under the condition of 500°C with limited oxygen, and the obtained solid product is pulverized and sieved, and the particle size is controlled between 0.2-5mm. The remaining sludge from anaerobic digestion was used as inoculum sludge.

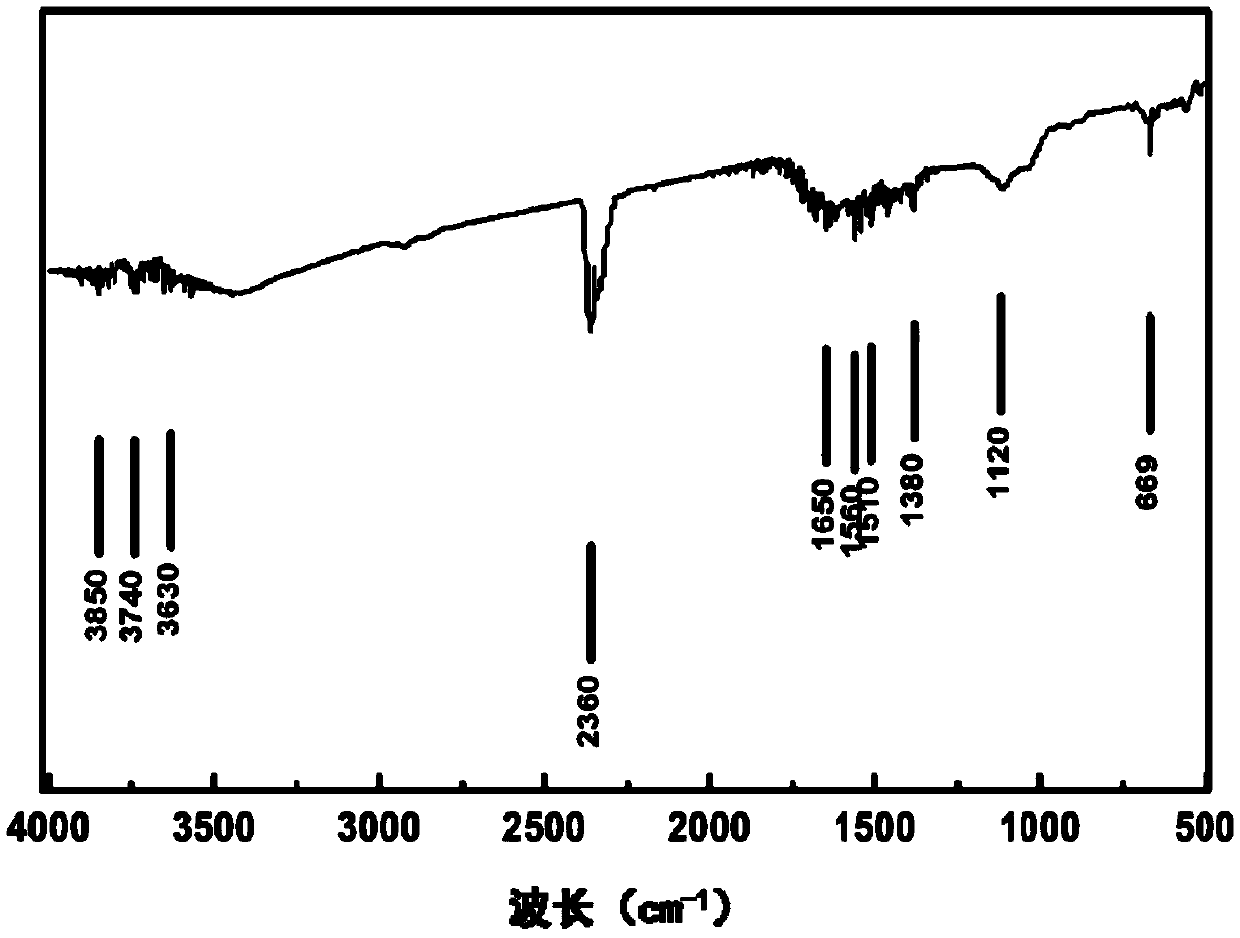

[0037] Analyze the specific surface area and porosity of the thermally cracked solid product, and observe the microstructure through the scanning electron microscope image of the thermally cracked solid product, such as figure 1 Shown; Determination of the Fourier transform infrared spectrum of the thermally cracked solid product, such as figure 2 shown.

[0038] From figure 1 It can be s...

Embodiment 2

[0042] The solid product of biogas residue pyrolysis obtained in Example 1 was mixed with the inoculation sludge at a mass ratio of 1:2, and cultured at 35°C for 24 hours to enhance the activity of inoculation microorganisms to prepare enhanced inoculation sludge for future use.

[0043] Put the sludge and garden waste into the anaerobic digestion reactor, and at the same time add the solid product of biogas residue pyrolysis obtained in Example 1, and inoculate the enhanced inoculation sludge, and carry out anaerobic digestion under medium temperature conditions (35°C). The solid product of biogas residue pyrolysis accounted for 1% of the total solid content in the anaerobic digestion system, and the enhanced inoculated sludge accounted for 2% of the total solid content in the anaerobic digestion system. The experimental results showed that compared with the anaerobic digestion system only inoculated with conventional inoculated sludge, the introduction of solid products from ...

Embodiment 3

[0045] The solid product of biogas residue pyrolysis obtained in Example 1 was mixed with the inoculated sludge at a mass ratio of 1:1, and cultured at 35°C for 24 hours to enhance the activity of inoculated microorganisms to prepare enhanced inoculated sludge for future use.

[0046] Put the sludge and garden waste into the anaerobic digestion reactor, and at the same time add the solid product of biogas residue pyrolysis obtained in Example 1, and inoculate the enhanced inoculation sludge, and carry out anaerobic digestion under medium temperature conditions (35°C). The solid products of biogas residue pyrolysis accounted for 2% of the total solid content in the anaerobic digestion system, and the enhanced inoculated sludge accounted for 2% of the total solid content in the anaerobic digestion system. The experimental results showed that compared with the anaerobic digestion system only inoculated with conventional inoculated sludge, the introduction of solid products from bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com