Continuous thermal hydrolysis pretreatment process capable of reinforcing high temperature anaerobic fermentation of residual sludge

A technology of high-temperature anaerobic fermentation and excess sludge, applied in biological sludge treatment, sludge treatment through temperature control, etc., can solve the problems of heat consumption and heat loss, and achieve energy saving, processing capacity improvement, and efficiency improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

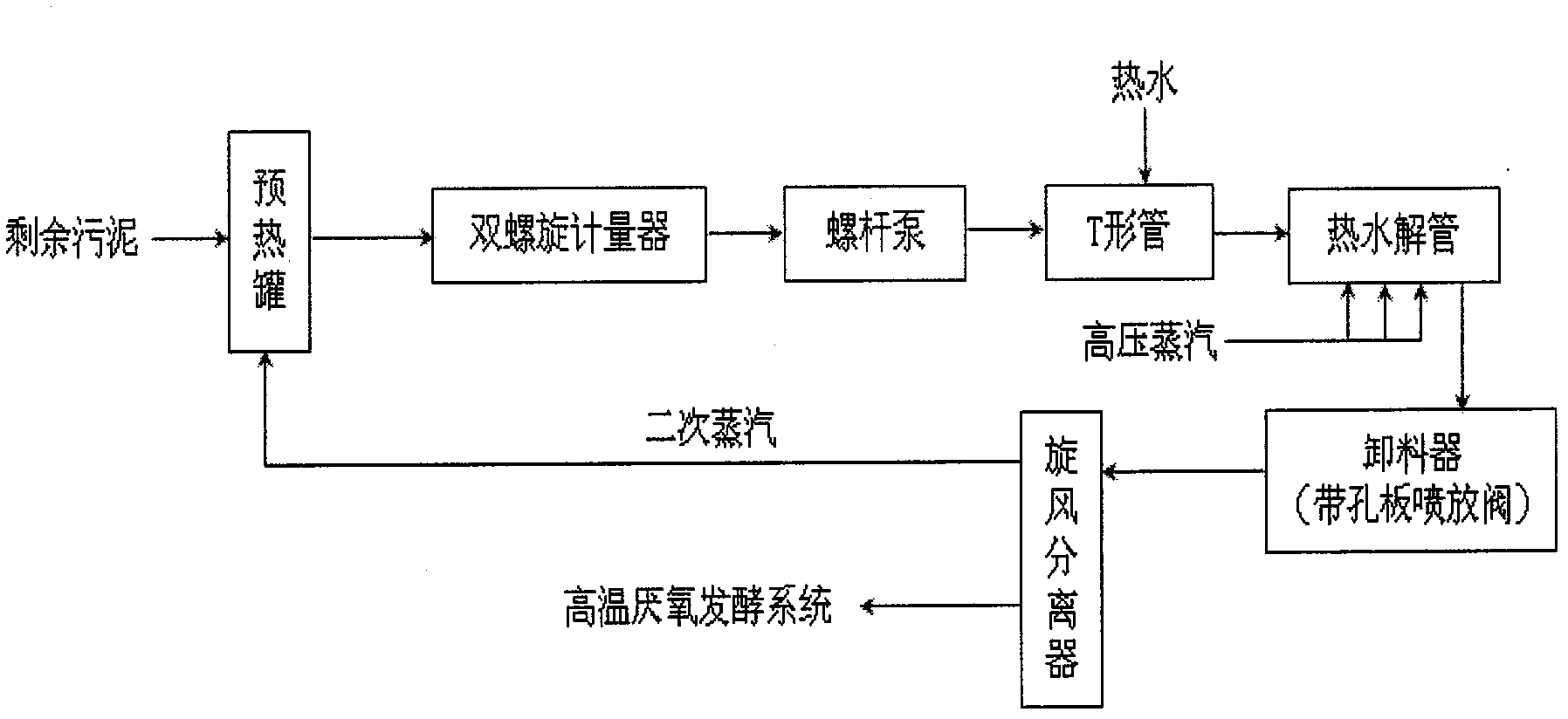

[0022] After the remaining sludge with a water content of 75% in the urban sewage treatment plant is transported to the preheating tank, it is preheated by the secondary steam from the cyclone separator. The temperature of the sludge after heating is 85 °C; the preheated sludge The screw pump is continuously and quantitatively pumped into the T-shaped pipe through the double-screw meter, and then enters the thermal hydrolysis pipe together with the hot water injected above the T-shaped pipe at a temperature of 80°C to adjust the moisture content of the sludge to 80%. For the sludge in the thermal hydrolysis pipe, multi-point injection of steam with a pressure of 1.0MP and a temperature of 184°C is used for thermal hydrolysis treatment for 60 minutes, and then sprayed into the cyclone separator through the unloader with orifice plate discharge valve In the process, the sludge with a solid content of 11% in the cyclone separator is sent to the high-temperature anaerobic fermentat...

Embodiment 2

[0024] After the remaining sludge with a moisture content of 80% in the urban sewage treatment plant is transported to the preheating tank, it is preheated with the secondary steam from the cyclone separator. The temperature of the sludge after heating is 90 °C; the preheated sludge The double-screw meter is continuously and quantitatively pumped into the T-shaped pipe by the screw pump, and the hot water with a temperature of 82°C is injected into the thermal hydrolysis pipe at a certain ratio above the T-shaped pipe to adjust the moisture content of the sludge to 83%. . For the sludge in the thermal hydrolysis pipe, multi-point injection of steam with a pressure of 1.1MP and a temperature of 186°C is used for thermal hydrolysis treatment for 30 minutes, and then it is sprayed into the cyclone separator through the unloader with an orifice discharge valve In the process, the sludge with a solid content of 10% in the cyclone separator is sent to the high-temperature anaerobic ...

Embodiment 3

[0026] After the excess sludge with a moisture content of 83% in the urban sewage treatment plant is transported to the preheating tank, it is preheated by the secondary steam from the cyclone separator. The temperature of the sludge after heating is 80 ° C; the preheated sludge The screw pump is continuously and quantitatively pumped into the T-shaped pipe through the double-screw meter, and the hot water with a temperature of 78°C is injected into the thermal hydrolysis pipe in a certain proportion with the top of the T-shaped pipe to adjust the moisture content of the sludge to 85%. . For the sludge in the thermal hydrolysis pipe, multi-point injection of steam with a pressure of 0.9MP and a temperature of 182°C is used for thermal hydrolysis treatment for 10 minutes, and then sprayed into the cyclone separator through the unloader with an orifice discharge valve In the process, the sludge with a solid content of 13% in the cyclone separator is sent to the high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com