Membrane contactor-based anaerobic digestive treatment system for side-flow recovery of ammonia nitrogen

An anaerobic digestion, membrane contactor technology, applied in biological sludge treatment, biochemical instruments, sterilization methods, etc., can solve the problems of complex sewage treatment system facilities, large scale, increased treatment costs, etc., to weaken the inhibition of ammonia nitrogen effect, reduced usage, low disposal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

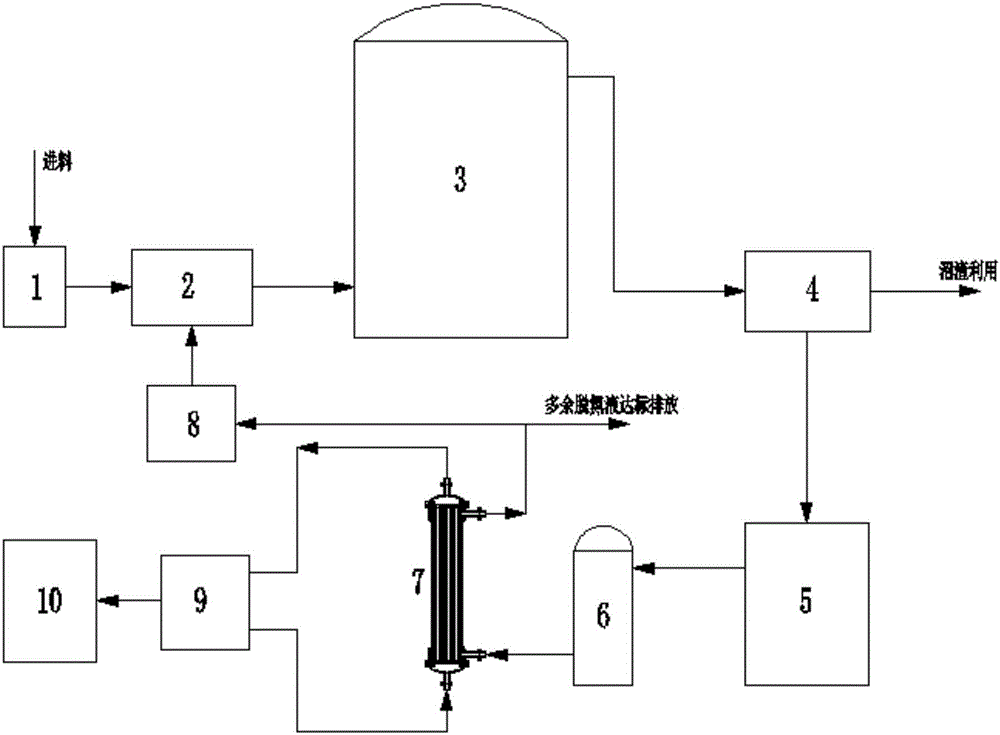

[0021] The kitchen waste treatment plant in a venous industrial park in the south has a processing scale of 100t / d (with an average solid content of 24%). It collects and treats kitchen waste from canteens, large hotels and resorts of enterprises and institutions in a certain city. The process is an anaerobic digestion treatment system with membrane contactor side flow recovery of ammonia nitrogen, that is, pretreatment (sorting + screening + crushing + cooking to remove oil) + anaerobic digestion + solid-liquid separation, biogas residue is composted and sold as organic fertilizer , The biogas slurry adopts the side flow of the membrane contactor to recover the ammonia nitrogen and uses it as the feed preparation water, and the rest reaches the standard and is discharged.

[0022] The food waste is first sorted, screened, crushed, cooked and deoiled in the pretreatment device (1). After the treatment, the average solid content of the food waste is 24%, and the ammonia nitrogen...

Embodiment 2

[0029] The sludge treatment and disposal center in a certain city in Hebei Province, with a processing scale of 300t / d (20% solid content), collects and treats dewatered sludge produced by municipal sewage treatment plants in a certain city. The process is an anaerobic digestion treatment system with side flow recovery of ammonia nitrogen with a membrane contactor, that is, sludge silo + homogeneous tank + anaerobic digestion + solid-liquid separation, the biogas residue is composted as nutrient soil, and the biogas slurry adopts a membrane contactor Ammonia nitrogen is recovered from the side stream and used as feed preparation water, and the rest is discharged out when it reaches the standard.

[0030] The sludge from the sewage treatment plant is sent to the pretreatment device (1) of the sludge treatment center through a sealed vehicle. The pretreatment device (1) includes a sludge silo, a conveyor, and a pulper; after pretreatment, the ammonia nitrogen content of the sludg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com