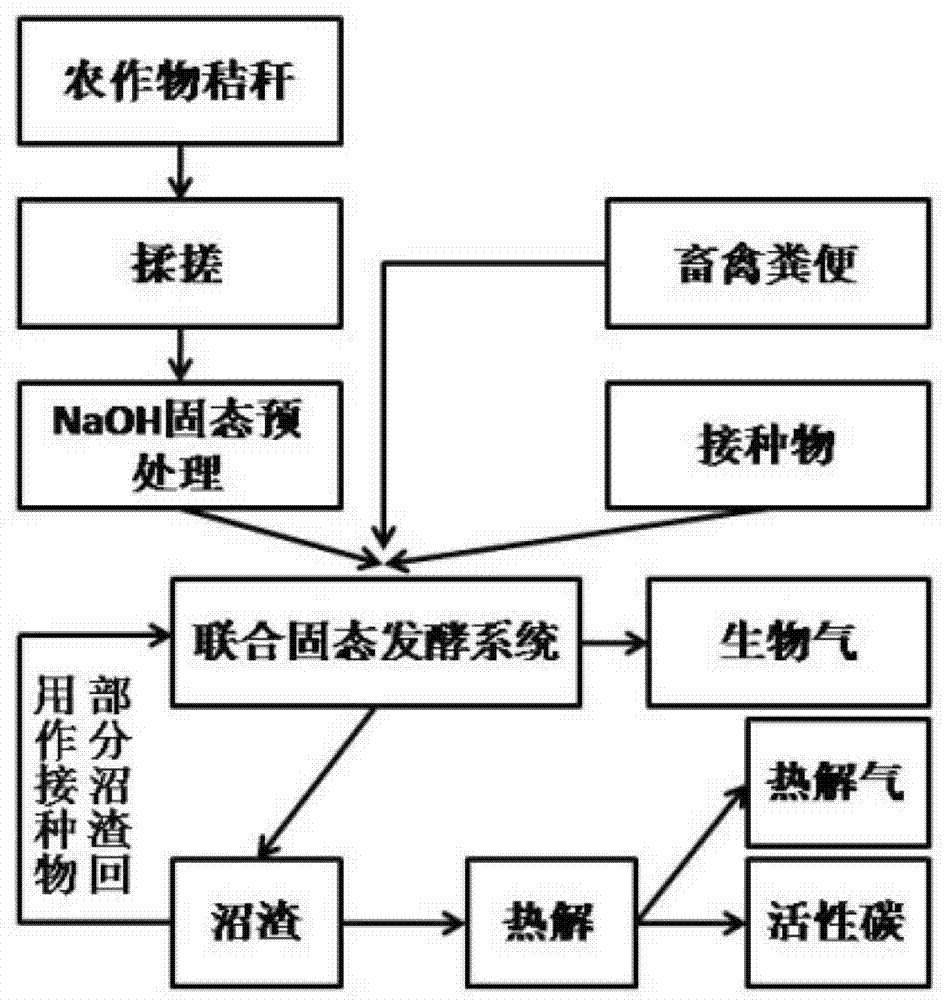

Method for producing biogas by combined solid state fermentation of crop straws and excrements of livestocks

A technology of crop straw and solid-state fermentation, applied in fermentation, waste fuel, biological sludge treatment, etc., can solve the problems of long residence time, poor development and utilization, and limitation of large-scale utilization, etc., and achieve gas production efficiency High, optimize the effect of preprocessing time and structure configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The first choice is to put 500g of crop straw with a total solid concentration of 0.95 and a volatile solid concentration of 0.9 after kneading into a 5L container, add 23.75g of NaOH, and then add 268g of water. After mixing evenly, seal and store at 20°C for 1 day. Take it out, add 800g of livestock and poultry manure with a volatile solid concentration of 0.2, and then add 1600g of inoculated sludge with a volatile solid concentration of 0.1, so that the solid content of the entire fermentation system is 25%, mix well and put it into an 8L anaerobic reactor middle. The reactor temperature was controlled at 50°C by a water bath jacket. After 21 days of high-temperature solid-state fermentation, it was taken out, and 30% of the biogas residue was used as an inoculum for the next batch of anaerobic fermentation. The remaining 70% of the biogas residue is passed into the pyrolysis reactor for pyrolysis. During pyrolysis, the pyrolysis temperature is 600°C, the heating ...

Embodiment 2

[0021] The first choice is to put 500g of crop straw with a total solid concentration of 0.95 and a volatile solid concentration of 0.9 after kneading into a 5L container, add 25g of NaOH, and then add 300g of water. After mixing evenly, seal and store at 20°C for 1 day. Take it out, add 750g of livestock and poultry manure with a volatile solid concentration of 0.2, and then add 2000g of inoculated biogas residue with a volatile solid concentration of 0.1, so that the solid content of the entire fermentation system is 22%, mix well and put it into an 8L anaerobic reactor middle. The reactor temperature was controlled at 50°C by a water bath jacket. After 24 days of high-temperature solid-state fermentation, it was taken out, and 30% of the biogas residue was used as an inoculum for the next batch of anaerobic fermentation. The remaining 70% of the biogas residue is passed into the pyrolysis reactor for pyrolysis. During pyrolysis, the pyrolysis temperature is 800°C, the hea...

Embodiment 3

[0023] The first choice is to put 500g of crop straw with a total solid concentration of 0.95 and a volatile solid concentration of 0.9 after kneading into a 5L container, add 16g of NaOH, and then add 255g of water. After mixing evenly, seal and store at 20°C for 3 days. Take it out, add 2000g of livestock and poultry manure with a volatile solid concentration of 0.2, and then add 3000g of inoculated sludge with a volatile solid concentration of 0.1 to make the solid content of the entire fermentation system 25%, mix well and put it into an 8L anaerobic reactor middle. The reactor temperature was controlled at 50°C by a water bath jacket. After 24 days of high-temperature solid-state fermentation, it was taken out, and 30% of the biogas residue was used as an inoculum for the next batch of anaerobic fermentation. The remaining 70% of the biogas residue is passed into the pyrolysis reactor for pyrolysis. During pyrolysis, the pyrolysis temperature is 700°C, the heating rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com