Method for preparing volatile fatty acid with high solid concentration organic castoff heat-alkali preprocessing post anaerobic fermentation

A technology of volatile fatty acids and high solid concentration, which is applied in the field of organic solid waste recycling, can solve the problems of unoptimistic economic benefits and low added value of products, and achieve shortened fermentation cycle, high production intensity and high conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

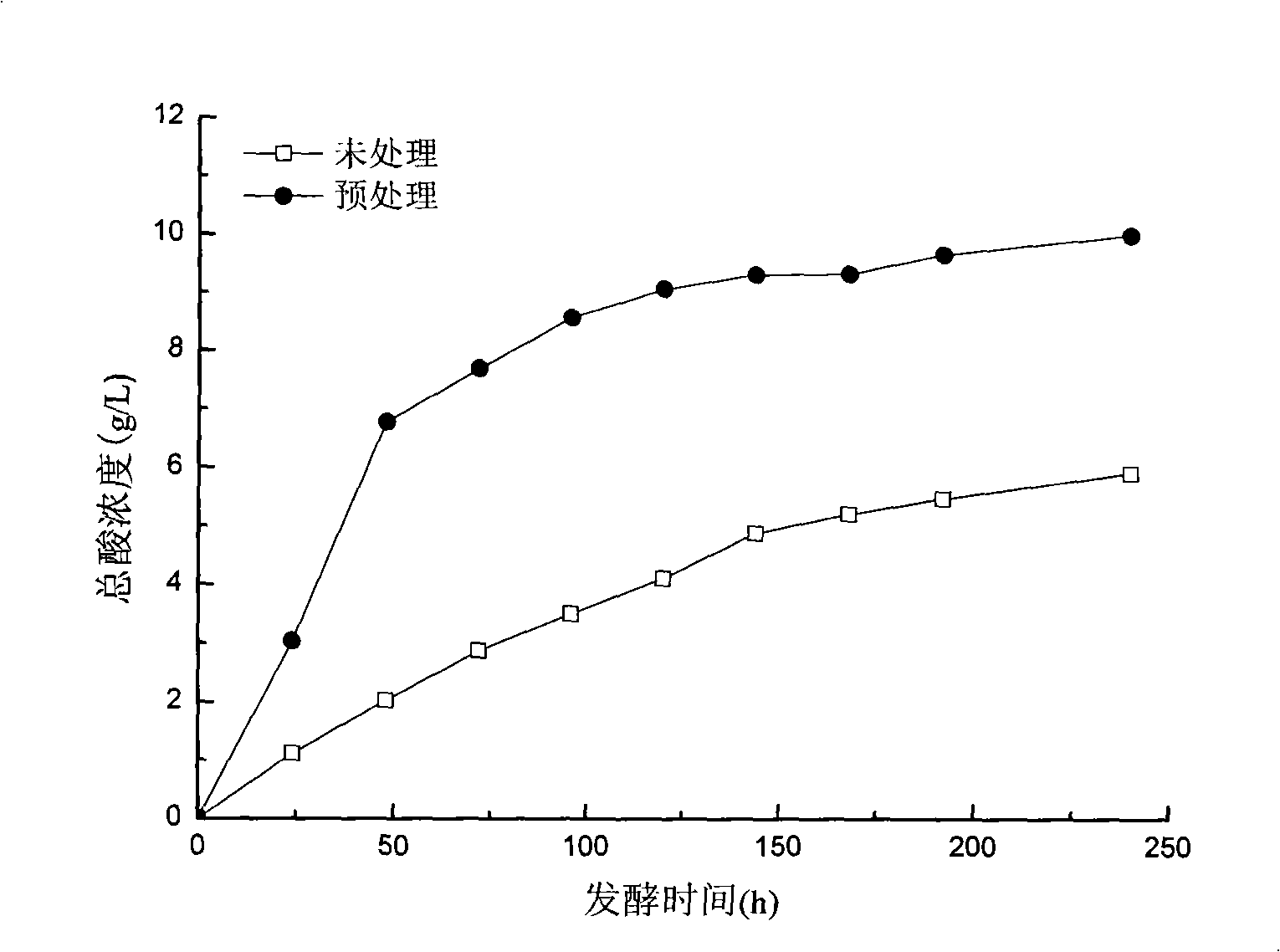

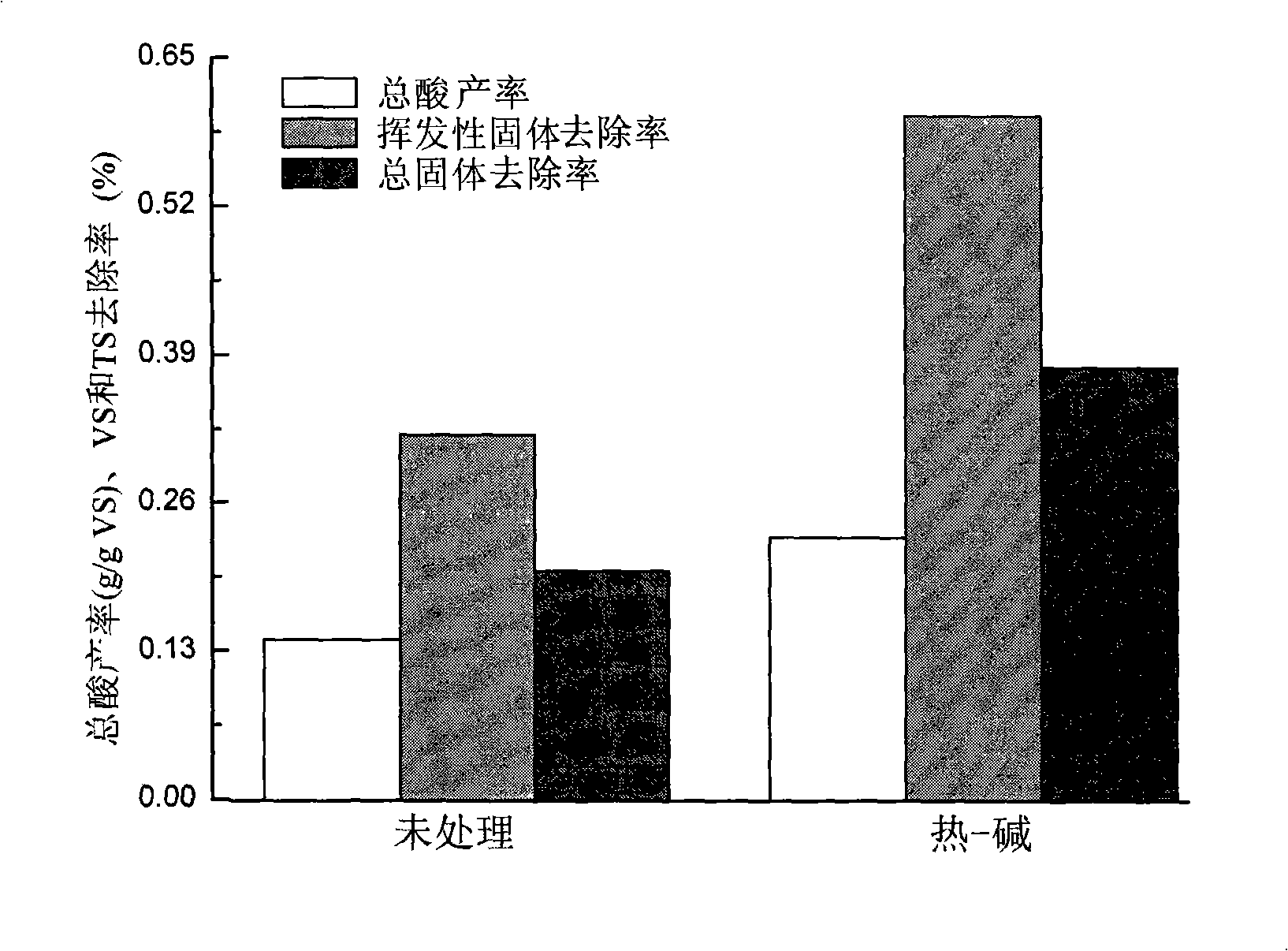

Embodiment 1

[0017] The pH of the prepared urban sludge mixture with a solid mass concentration of 7.4% was adjusted to 12.0, sealed and placed at 90° C. for 2 hours with slow stirring for pretreatment. After pretreatment, 10g of VS / L anaerobic acidified seed slime that had been subjected to heat stress treatment and domestication was added, filled with nitrogen for 3 minutes, sealed, and fermented at 35°C for 10 days, using a shaking table for fermentation at a speed of 120r / min. The pH of the fermentation process was controlled at 10. The unpretreated municipal sludge was prepared to the same solid concentration, the pH was not controlled during the fermentation process, and the rest of the fermentation conditions were the same as those of the pretreated sludge. A comparison of acid production from municipal sludge without pretreatment and pretreatment figure 1 and figure 2 . Compared with untreated, the total acid production increased by 61.0% after pretreatment, and the acid produc...

Embodiment 2

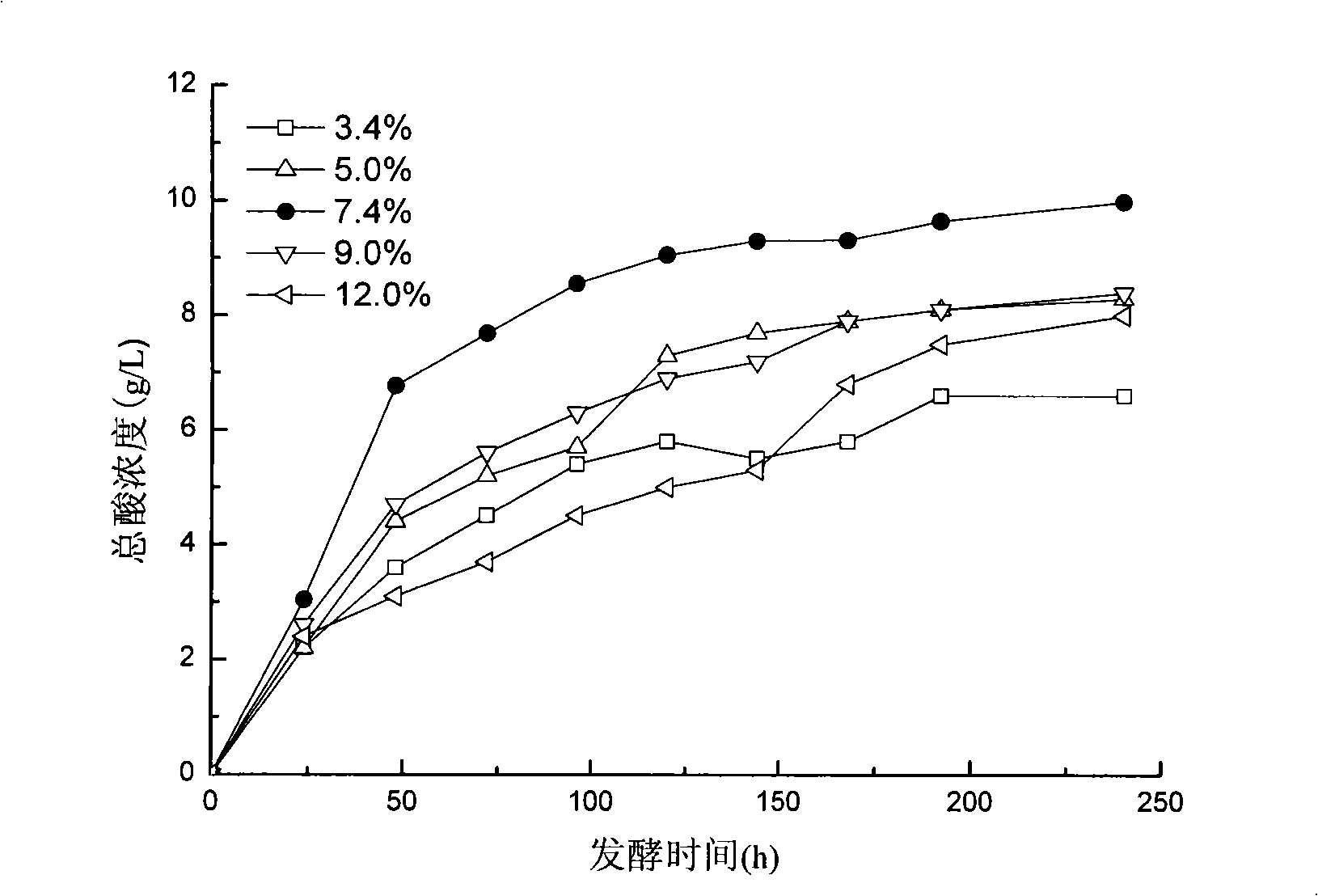

[0019] The municipal sludge mixed solutions with solid mass concentrations of 3.7%, 5.0%, 7.4%, 9.0% and 12.0% were prepared respectively. Pretreatment conditions and anaerobic fermentation acid production conditions are the same as in Example 1. The process change of total acid production under different solid mass concentration conditions is shown in image 3 . The volatile fatty acid yield of the pretreated municipal sludge with a solid mass concentration of 7.4% was the highest, and compared with other solid mass concentrations, the yield increased by 18.7%-51.1%.

Embodiment 3

[0021] Prepare a solid mass concentration of 7.4% urban sludge mixture. The pretreatment conditions are the same as in Example 1. Then, 10 g VS / L of domesticated seed mud was inserted, filled with nitrogen for 3 minutes, sealed, and fermented at 35° C. for 10 days, and fermented on a shaking table at a speed of 120 r / min. The pH of the fermentation process was controlled at 8, 9, 10, 11 and 12, respectively. Under different pH conditions, the process change of total acid production is shown in Figure 4 . The total acid production was the highest when the fermentation process was at pH 10. Compared with other pH conditions, the acid production increased by 4.5%-236.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com