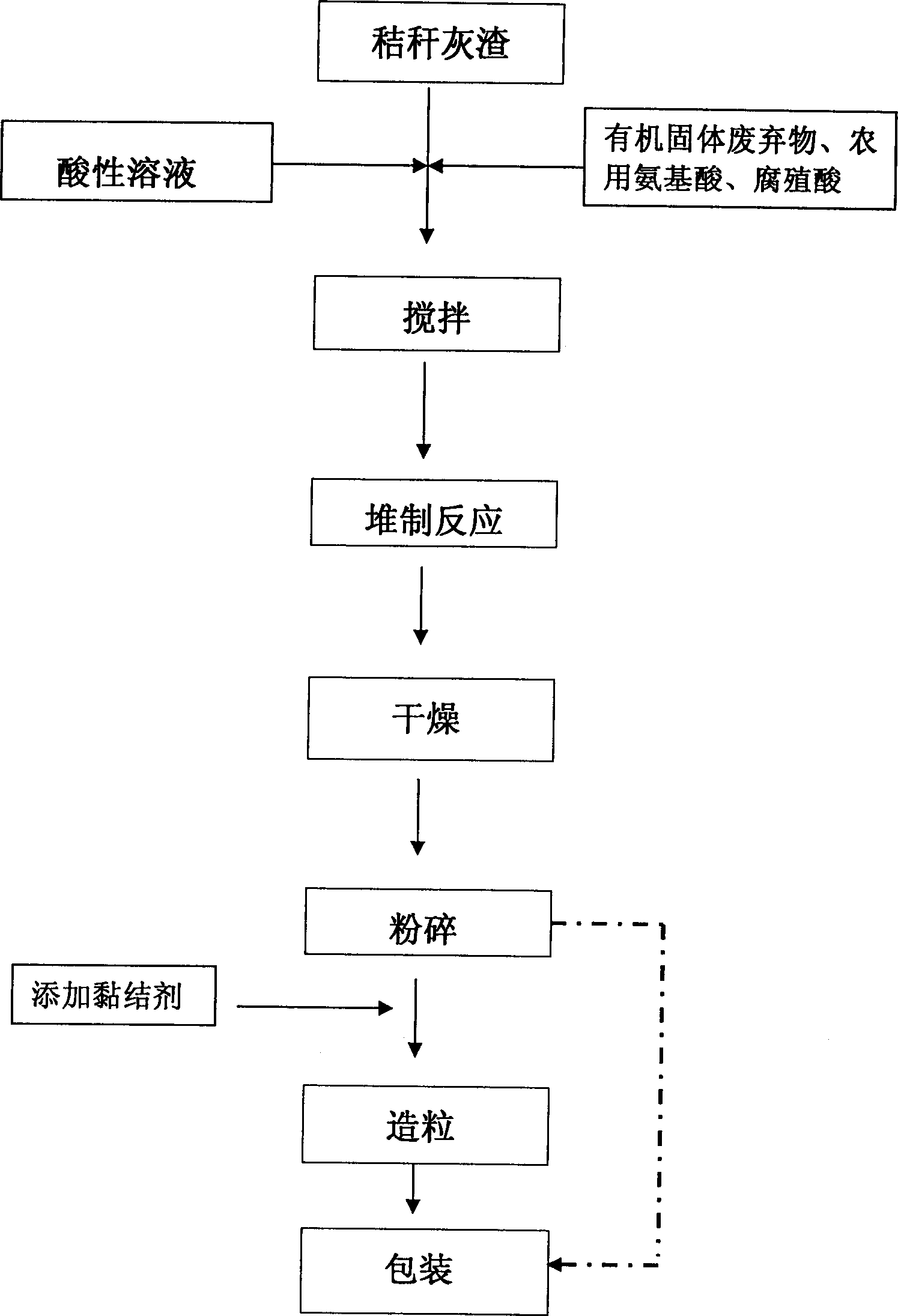

Process for producing multielement fertilizer by plant straw ash

A plant straw and multi-element technology, which is applied in the preparation, application and application of organic fertilizers, can solve the problems of low availability of plant nutrients, improve the utilization rate of nutrients, facilitate packaging, transportation and application, and achieve high activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Get 700kg of straw ash, 40kg of waste sulfuric acid (concentration is 70-80%) and 300kg of water, first dissolve sulfuric acid in water to make dilute acid solution, then slowly add dilute acid solution in the stirring process, the final water content of the material is controlled at 30%, the pH is about 7.0. After stirring evenly, put it into a concrete pool or other reaction container and seal it for 1 day. After 1 day, take it out and dry it, crush it, add 25kg of modified starch, granulate it in a disk, and then pack it.

Embodiment 2

[0036] Take 600kg of straw ash, add 300kg of citric acid residue, and add water until the water content of the material is about 40%. After fully stirring with a mixer, put it into a concrete pool and seal it for 10 days. After 10 days, take it out and dry it, crush it, and pack it.

Embodiment 3

[0038] Take 650kg of straw ash, add 250kg of fresh cow manure, and add water until the moisture content of the material is about 35%. After fully stirring with a mixer, put it into a concrete pool and seal it for 7 days. After 7 days, take it out and dry it, pulverize it, add 25kg of modified starch, carry out extrusion granulation and pack it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com