Fermented fungus chaff feed for goose

A technology for fermenting bacteria and feed, applied in animal feed, animal feed, applications, etc., can solve problems such as environmental degradation, achieve the effects of reducing toxic and harmful substances, broad development prospects, and balanced and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

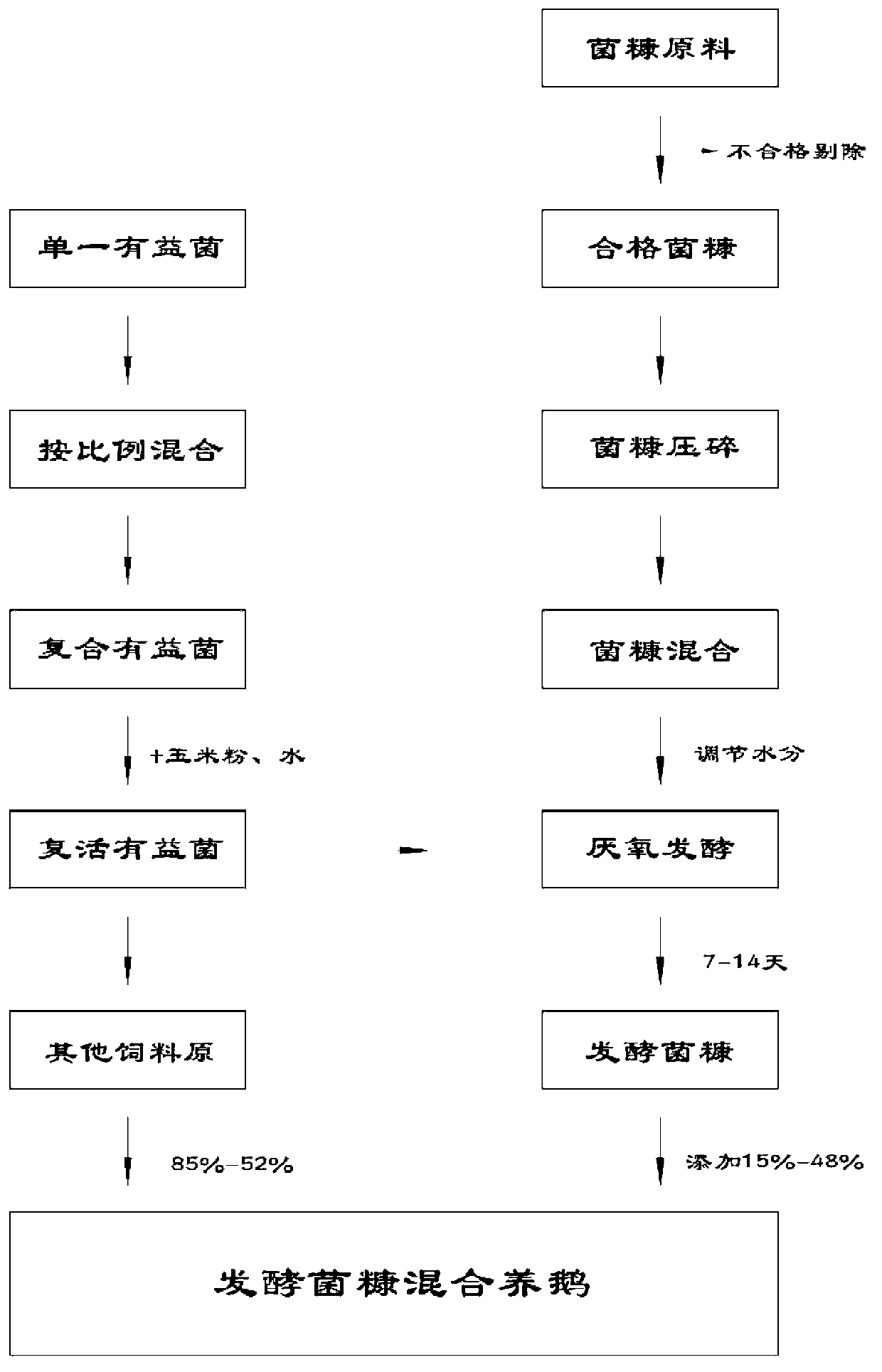

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, raising 200 Langde geese with fermented bacterium chaff

[0017] 1) Production of fermented fungus chaff Take 2,000 kg of fungus chaff (bacteria bag) after cultivating oyster mushrooms, remove the moldy, deteriorated and blackened parts, and press them into granules with a hay cutter. Mix 2 kg of self-made compound micro-ecological preparation with 100 kg of corn flour and 4 kg of salt, and then add appropriate amount of water to revive the beneficial bacteria. After 2 to 4 hours, mix the above-mentioned crushed bacterial chaff and the revived beneficial bacteria evenly, and add 350 kg of water. Adjust the water content until it forms a ball in your hand and a small amount of water drops out from between your fingers. Put it into a cement tank and press it tightly, cover it tightly with a plastic film, and tightly compact it around it. The material pile is 1 meter high, 1.2 meters wide, and 2.5 meters long. The fermentation temperature is 26°C to 32°C. Co...

Embodiment 2

[0022] Example 2. Feeding 600 Hepu geese with fermented fungus chaff and sweet corn stalks

[0023] 1) Production of fermented bacteria chaff Take 6 kg of self-made compound micro-ecological preparations, mix them with 300 kg of corn flour and 12 kg of salt, and then add appropriate amount of water to revive the beneficial bacteria for 2 hours before use. Pick out 6,000 kilograms of fungus bags with white mycelium and no mildew after cultivating Zhenzhen mushrooms, and crush them with a hay cutter. Mix the above-mentioned crushed fungus chaff and the revived beneficial bacteria evenly, add 1500 kg of water to adjust the water to about 65%. Put a plastic film on the ground first, then pile the fermentation material into a pile with a height of 1.2 meters, an upper width of 1.4 meters, a lower width of 1.6 meters, and a length of 6.4 meters. ℃, fermented for 14 days to make a slightly yellow, soft, sour-flavored fermented biological feed. Feed the geese to take at any time, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com