Organic solid waste regeneration resource treatment method and apparatus system thereof

A technology of organic solids and renewable resources, applied in the removal of solid waste, biological organic part treatment, organic fertilizers, etc., can solve the problems of long heating time, high processing cost, low degree of automation, etc. Short fermentation time and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Collect 30 tons of food waste (water content 90%) every day, and about 20 tons of liquid substrate and 10 tons of solid substrate (water content 70%) can be separated. 10 tons of solid substrate and 3 tons of straw are processed by subcritical hydrolysis to obtain about 9-10 tons of fertilizer (after drying, the moisture content is 30%).

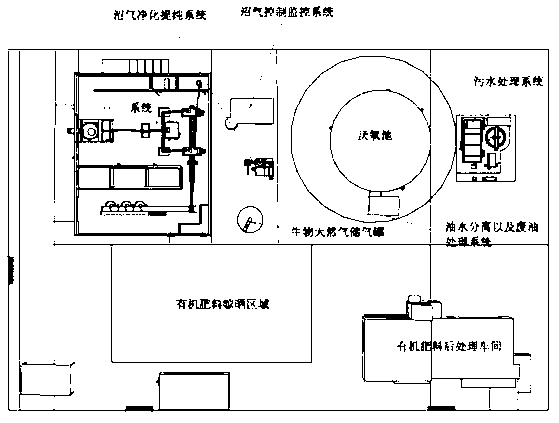

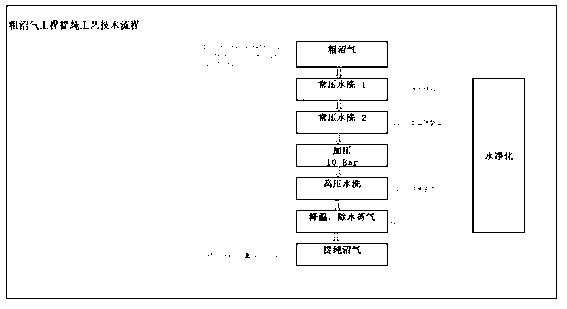

[0096] Add 1.15 tons of straw to 20 tons of liquid substrate for anaerobic fermentation, and the anaerobic fermentation tank can be used Figure 5 The anaerobic fermentation tank shown includes: a water storage tank (51), an oil storage tank (52), an anaerobic fermentation tank (53), a gas storage membrane (54), and a transition storage tank (55). It can produce 345 cubic meters of crude biogas, 18 tons of biogas slurry and 1.8 tons of biogas residue (moisture content 75%). Wherein the subcritical hydrolysis reactor adopts the fully intelligent subcritical hydrolysis double reactor of the applicant's previous application.

[0097] I...

Embodiment 2

[0099] Add 5 tons of straw to 100 tons of chicken manure per day, and after 30-35 days of anaerobic fermentation, 9500 cubic meters of crude biogas, 20 tons of biogas residue (75% moisture content) and 80 tons of biogas slurry will be produced. After adding 10 tons of straw to 20 tons of biogas residues, about 18 tons of fertilizers are obtained through subcritical hydrolysis (after drying, the moisture content is 30%). Biogas slurry treatment and reuse.

[0100] In 30-35 days, a total of 540 tons of fertilizers, 2,000 tons of clean water (domestic water, clean factory area), and tons of refined biogas (except for the biogas generated by the operation of the equipment in the present invention are all for their own use) were obtained.

[0101] According to the experimental results obtained in Examples 1 and 2, adjust the system parameters, prolong the running time of the system, and record the data. After 5 months of testing, it has been confirmed that after the entire plant a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com