Composting reactor

A composting reactor and reactor technology, applied in application, organic fertilizer, fertilization device, etc., can solve the problems of many types of equipment, large investment in civil engineering, large investment in equipment, etc., and achieve compact equipment structure, less land occupation, and high degree of automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

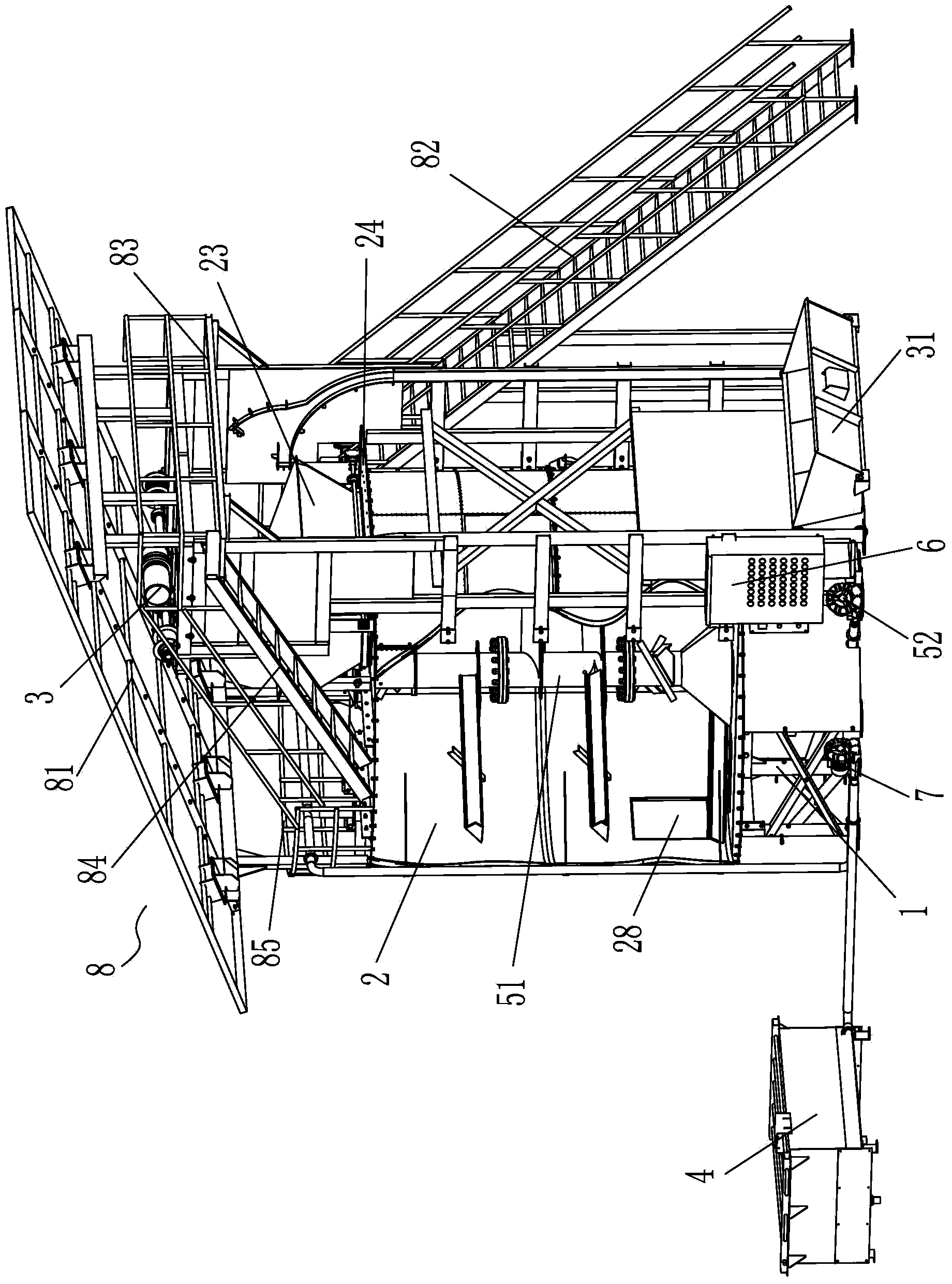

[0102] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0103] see figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the present invention. The composting reactor of the present invention is used for organic solid waste composting production, comprising:

[0104] The reactor frame 1 can be a welded structure composed of square tubes or H steel profiles, and is fixed on the foundation by embedded iron or anchor bolts;

[0105] An airtight reaction chamber 2 installed on the reactor frame 1, the airtight reaction chamber 2 is provided with a feed port 23;

[0106] The feeding device 3 is located on one side of the closed reaction chamber 2 and is arranged relative to the feed port 23, and is used to deliver organic solid waste raw materials into the closed reaction chamber 2;

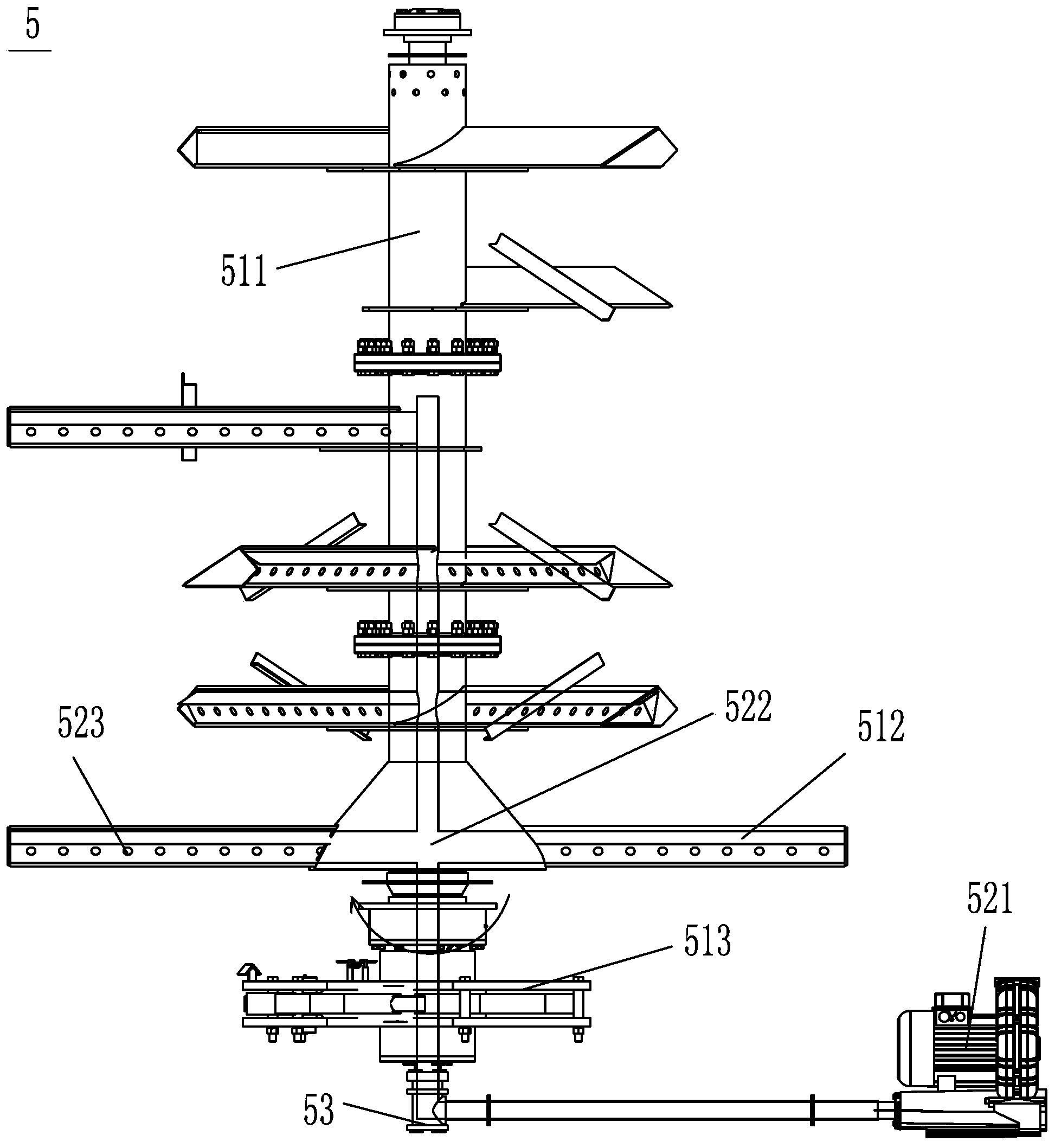

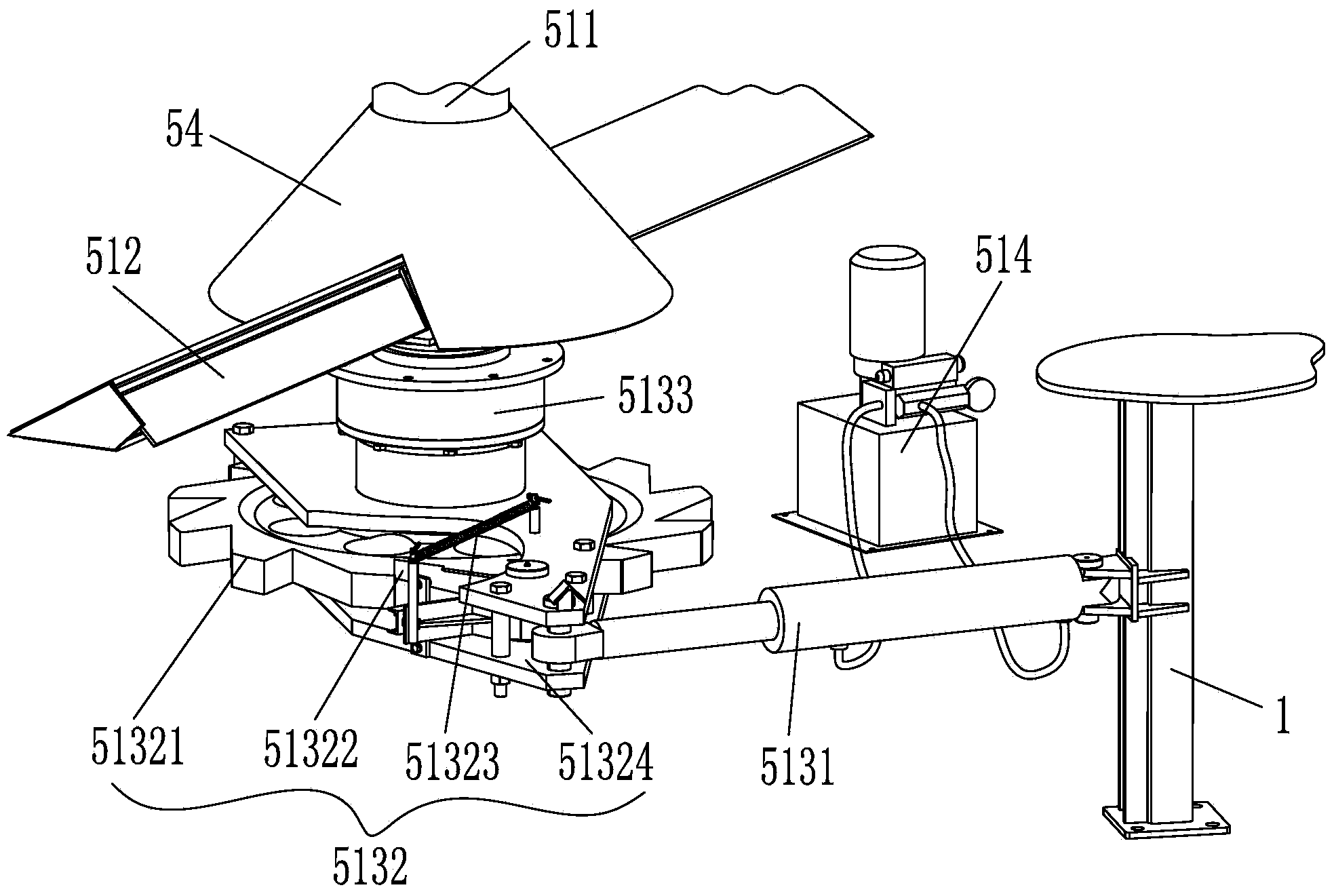

[0107] The aeration and stirring system 5 is partially installed in the clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com