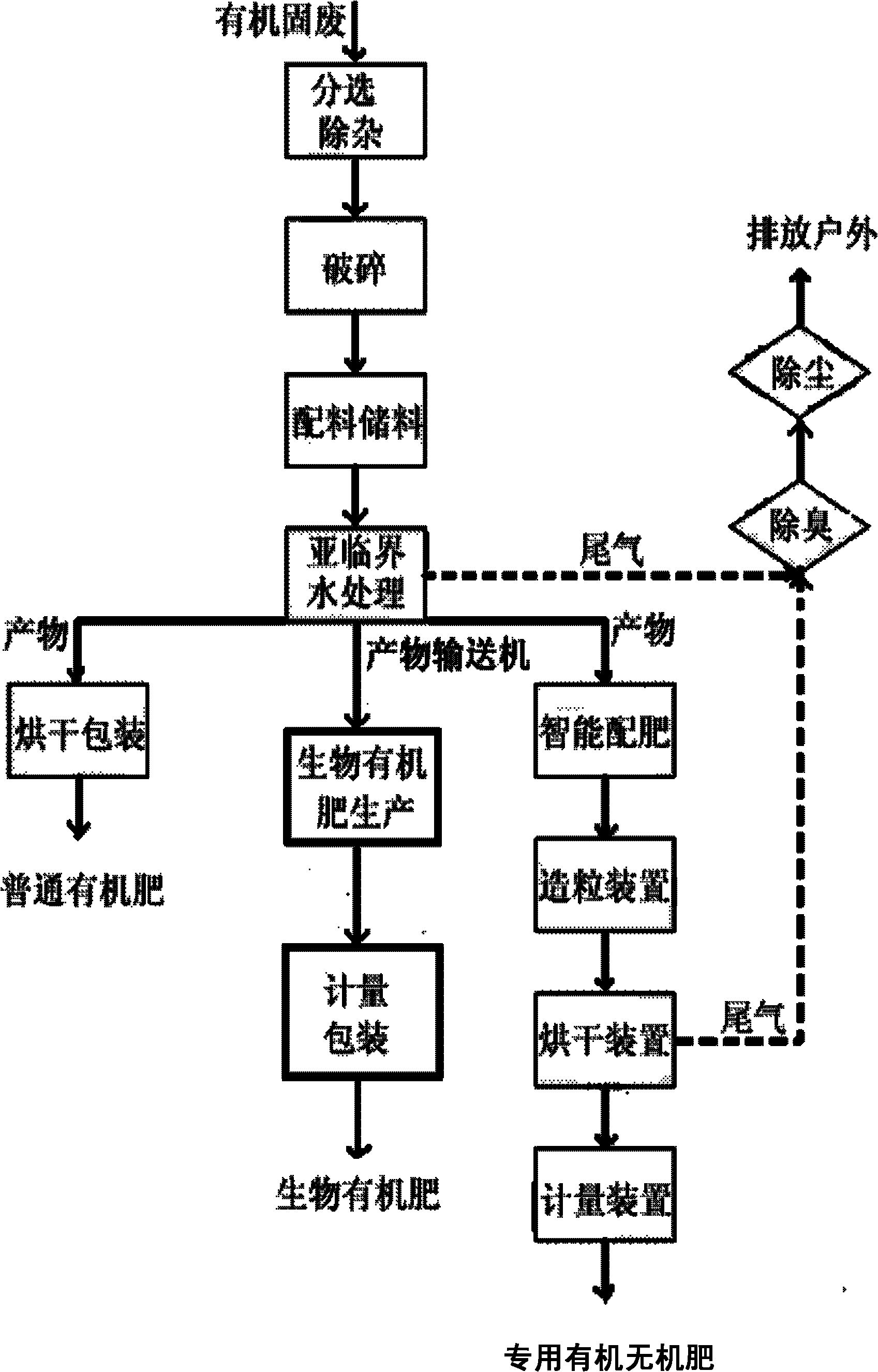

Method and equipment for producing organic fertilizer by utilizing subcritical water to process rural-urban organic solid waste

A technology of organic solid waste and subcritical water, applied in the direction of organic fertilizers, sewage/sludge fertilizers, fertilization devices, etc., can solve the problems of unreported treatment process, achieve the effect of water and fertilizer retention, high activity, chelation rate and The effect of enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

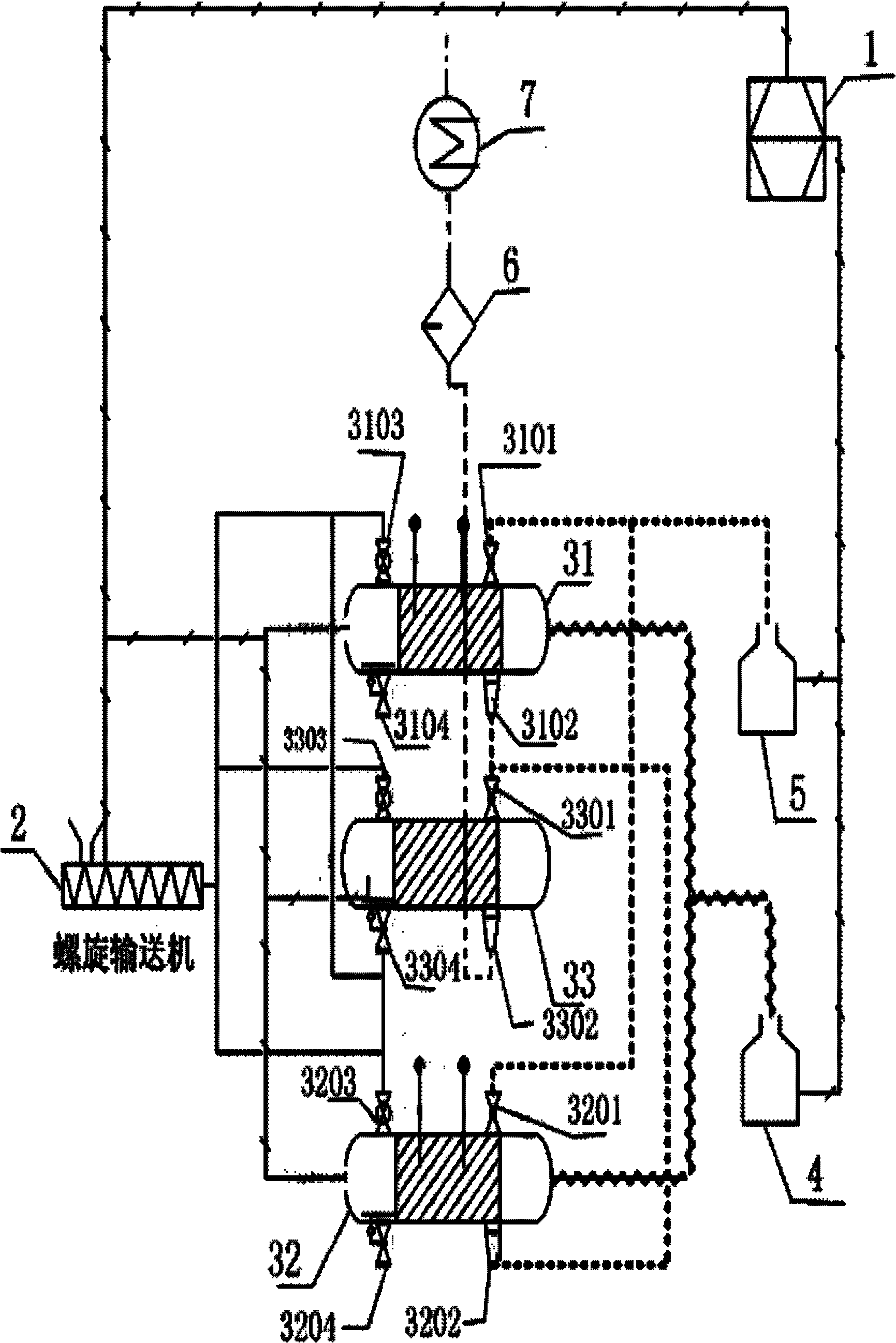

[0087] Using 2 sets of 3m 3 Sequence batch reactor, one 3m 3 The buffer tank is heated by a steam generator (specification steam volume 2t, 2MPa), and 5 tons of food waste and 4 tons of livestock and poultry manure are used to produce organic fertilizers.

[0088] 1. Garbage sorting and impurity removal: glass bottles, cans, wine bottle caps and some other metal objects in the kitchen waste.

[0089] 2. Crushing: crushing the sorted kitchen waste.

[0090] 3. Ingredients: 5 tons of kitchen waste (water content 75%), 4 tons of sawdust and straw, 500 kg of calcium magnesium phosphate fertilizer, 50 kg of zinc sulfate, 40 kg of borax, and 30 kg of manganese sulfate.

[0091] 4. The prepared materials are transported into the main reactor for processing: according to the test data, the batch processing time of the material reaction is about 10 minutes, heating time is 10 minutes, holding time is 30 minutes, and discharge time is 10 minutes. Input the control program that meets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com