Method for improving straw and excrement mixed anaerobic digestion gas production performance by biochemical pretreatment of maize straw

A technology of corn stalk and anaerobic digestion, applied in biological sludge treatment, waste fuel, fermentation and other directions, can solve the problems of unbalanced nutrition and difficult degradation, and achieve the effect of saving operation cost, low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

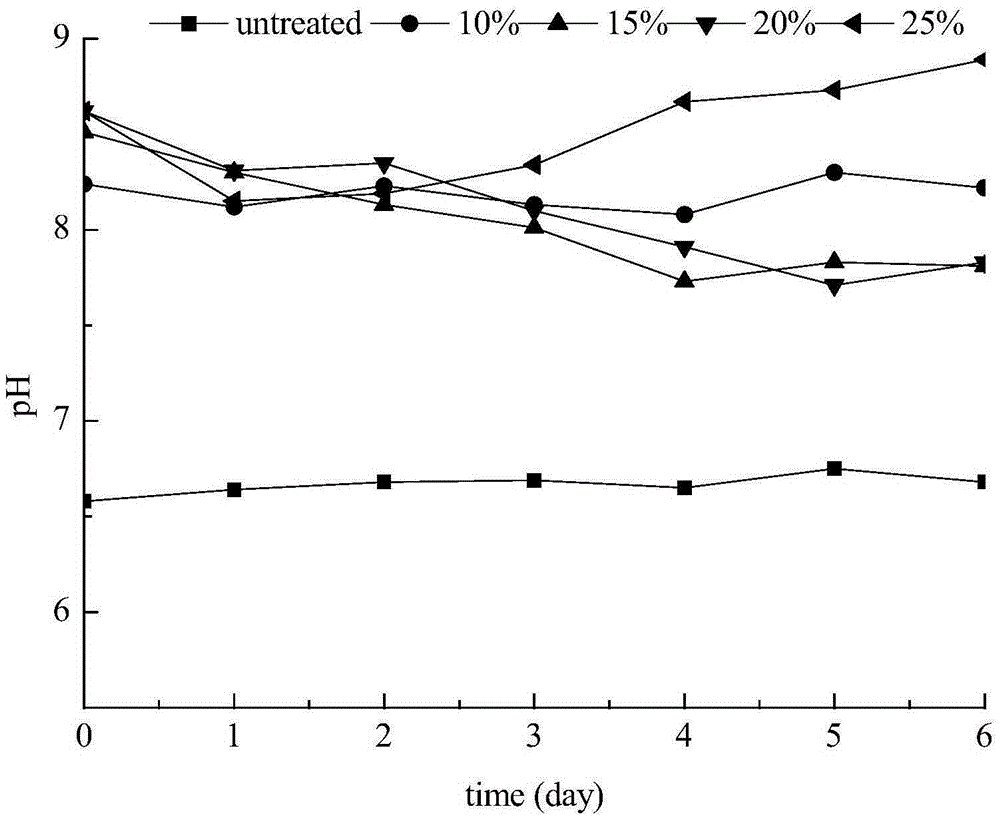

[0030] Get 48 parts by weight of 39g corn stalks (calculated as TS), use dry weight TS in 2%-4% biogas slurry (biogas slurry that passes through 5 mesh, 10 mesh, 20 mesh and 40 mesh filter screen) and total solids concentration (10%, 15%, 20% and 25%) two factorial design full factorial pretreatment experiments. The above biogas slurry was added to 48 parts of corn stalks and sealed at 35°C for 3 days.

[0031] After the pretreatment, 13g of cow manure (calculated as TS) and 12g of anaerobic digester sludge (calculated as TS) from a sewage treatment plant in normal operation were added as inoculum and mixed for anaerobic digestion reaction for 50 days. Record the daily biogas production by drainage method, and measure the percentage of methane every day, calculate the total methane production, and then calculate T 80 . The experimental results are as follows:

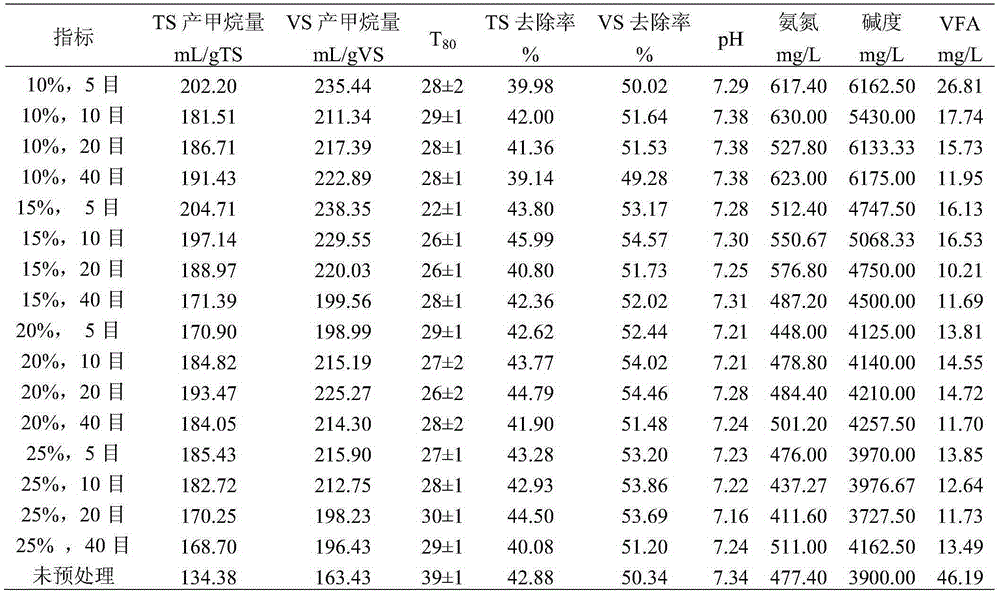

[0032] Table 1 Anaerobic digestion effluent properties

[0033]

[0034] Table 1 shows the amount of methane p...

Embodiment 2

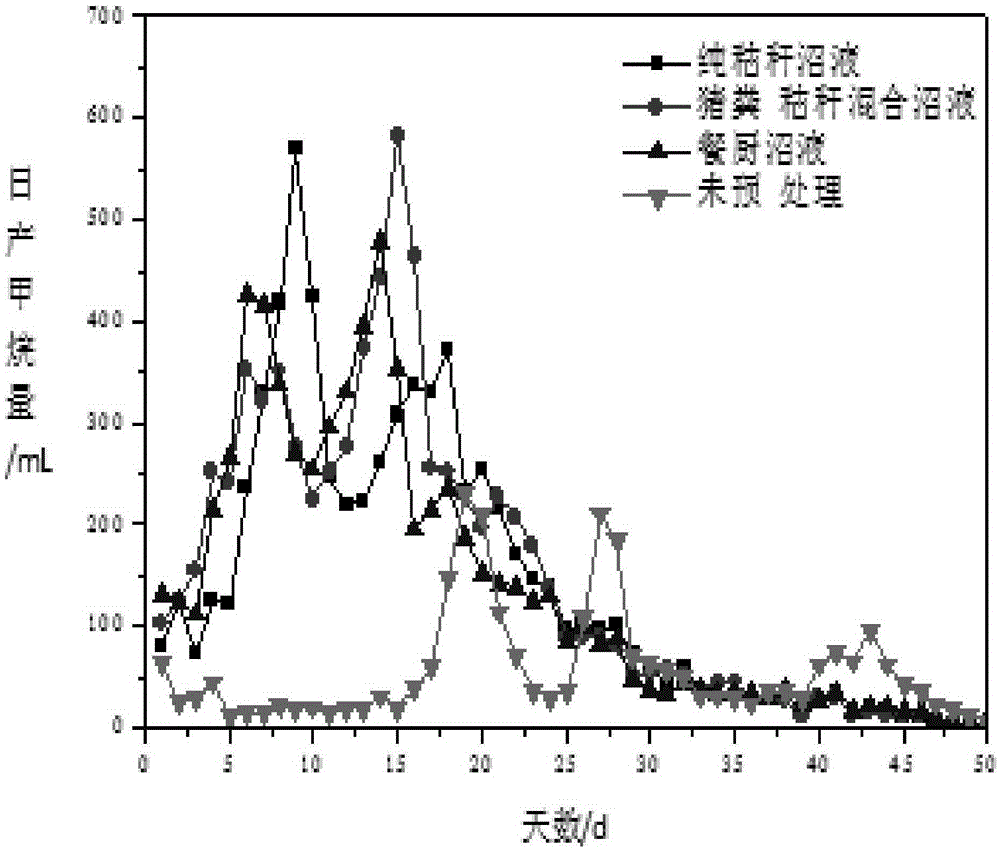

[0037] Weigh four parts of corn stalks, the amount of each part is 30g (calculated in TS), and use a 5-mesh sieve to collect 3:1 mixture of pure straw, straw and pig manure obtained from normal operation and stable fermentation for one year, and pure food kitchen waste. The output of the oxygen fermentation biogas digester is filtered, and the filtered biogas slurry is fully mixed with the crushed corn stalks according to 6 times the dry weight TS of the corn stalks. The pretreated corn stalks were sealed in ziplock bags, and pretreated at 35°C for 3 days, and the control group was unpretreated corn stalks.

[0038]The pretreated corn stalks were mixed with 10g of pig manure (calculated in TS) and 12g of sludge from the anaerobic digestion tank of a sewage treatment plant in normal operation (calculated in TS) as inoculum, added to the anaerobic digestion reactor, and tap water was added. to 80% of the reactor volume. Put the reactor filled with nitrogen gas and sealed after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com