Crushing equipment for cotton fiber reprocessing

A pulverizing equipment and reprocessing technology, applied in lighting and heating equipment, using liquid separating agent, drying, etc., can solve the problems of low work efficiency, inability to pulverize, inconvenient work, etc., to increase self-weight, facilitate pulverization, and improve pulverization. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

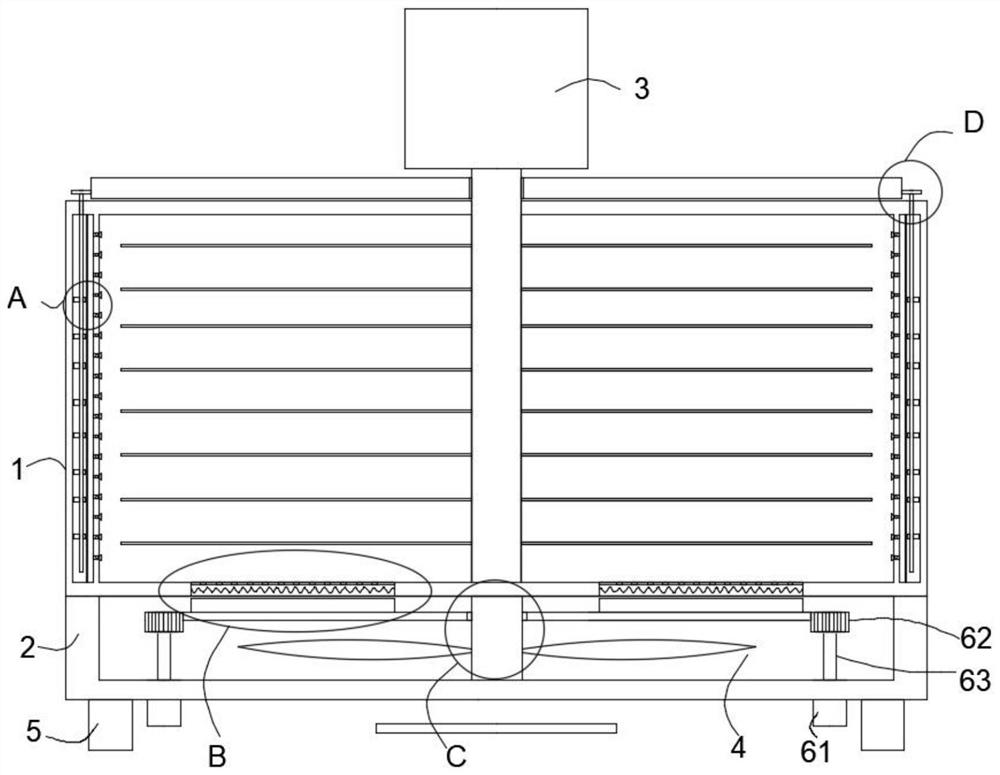

[0030] see Figure 1-6 , a kind of crushing equipment for cotton fiber reprocessing, comprising a crushing box 1, a central axis 30 arranged vertically is installed in the center of the crushing box 1, and a crushing motor 3 is installed on the top surface of the crushing box 1 to drive the center The shaft 30 rotates, and several crushing knives 27 are arranged on the outside of the central shaft 30 . Wherein the top surface of the crushing box 1 is fixed with a support frame 19 to install the crushing motor 3 above the crushing box 1 .

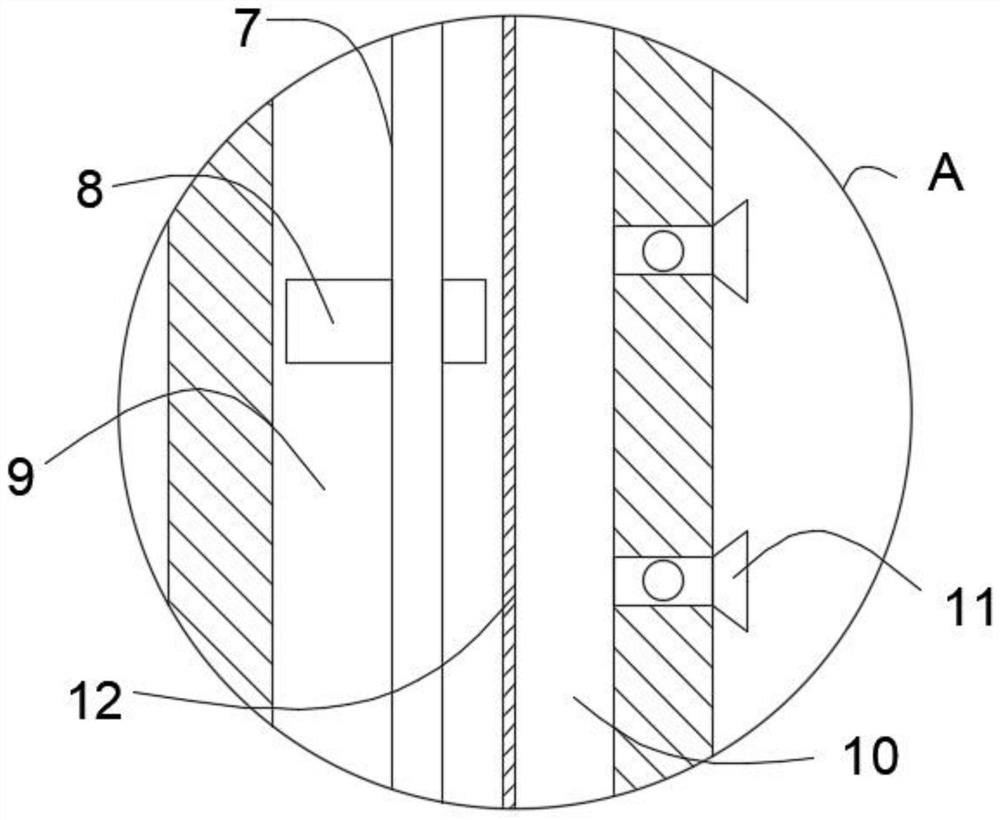

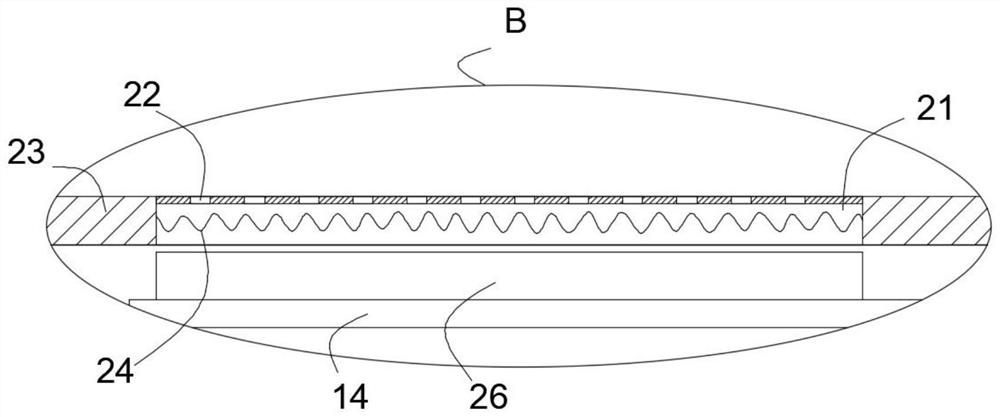

[0031] The casing of the crushing box 1 is distributed with several hollows in the circumferential direction, and a separation pad 12 is installed in the middle of the hollow, and the separation pad 12 separates the hollow to form an installation cavity 9 and a liquid storage chamber 10, wherein the liquid storage chamber 10 is adjacent to the crushing box 1 A number of liquid outlet holes are distributed on the shell of the inner cavity, a...

Embodiment 2

[0043] see Figure 7 as well as Figure 8 , in this embodiment, the outer wall of the central shaft 30 is provided with several sliding grooves 32 along its axial direction, and the outer side of the central shaft 30 is also provided with several sleeve plates 31 along the axial direction, and the outer wall of the sleeve plate 31 is distributed with slices Shaped crushing tool 27, while the inner wall of each sleeve plate 31 is fixed with a slide block 33 that slides and fits with the chute 32, and a driving member 29 is also fixed on the top of the inner wall of the crushing box 1, and the telescopic section of the driving member 29 and is located at the top. One cover plate 31 is fixed, and an elastic spacer 28 sleeved on the outside of the central axis is also installed between adjacent cover plates 31 .

[0044] The elastic spacer 28 of the above solution can be selected from a columnar spring, and the driver 29 can be selected from a miniature electric push rod.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com