Wax-free polishing method for ultrathin semiconductor wafer

A semiconductor and wafer technology, applied in the field of semiconductor preparation, can solve the problems of difficult infiltration of supply liquid, high fragmentation rate, high fragmentation rate, etc., and achieve the effects of weakening chlorine oxidation, not easy to float, and small fragmentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

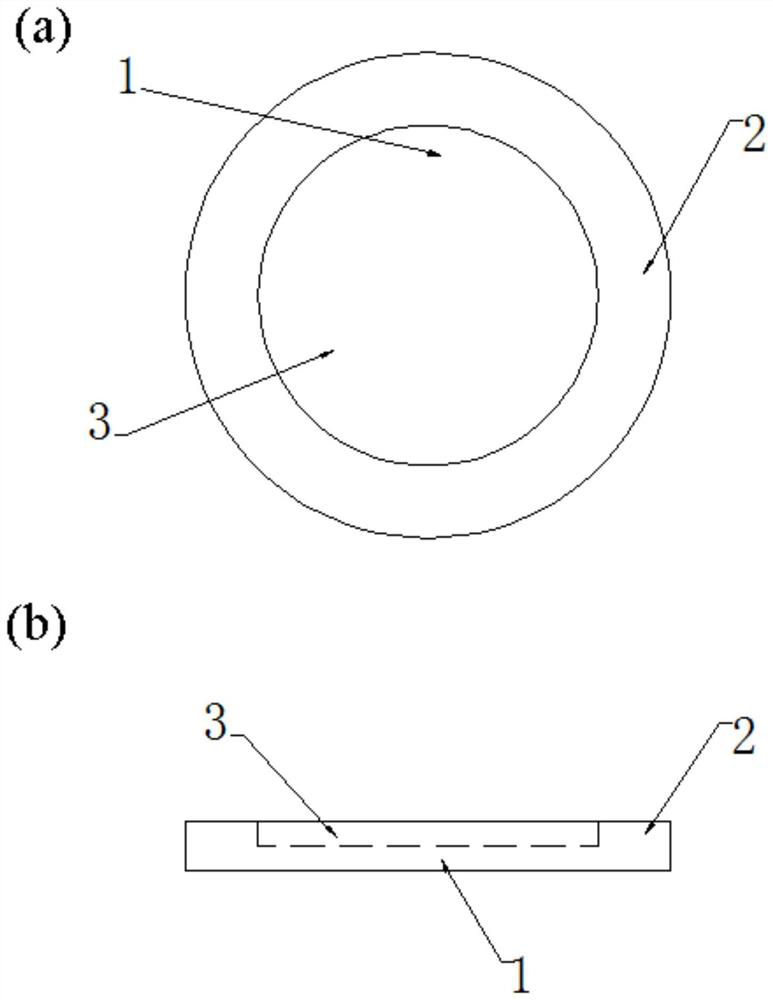

Image

Examples

Embodiment 1

[0034] The wax-free polishing method of a kind of ultra-thin semiconductor wafer as the embodiment of the present invention, described method comprises the following steps:

[0035] (1) Place the gallium arsenide wafer to be polished with a diameter of D on the adsorption pad mold A for rough back polishing, the adsorption pad mold A is provided with a round hole A, and the depth of the round hole A is 150-180 μm; The diameter of the circular hole A is (D+0.15)-(D+0.25) mm;

[0036] (2) Place the gallium arsenide wafer processed in step (1) on the adsorption pad mold B for rough polishing on the front side, the adsorption pad mold B is provided with a round hole B, and the depth of the round hole B is 120-150 μm ; The diameter of the circular hole B is (D+0.15)-(D+0.25) mm;

[0037] (3) Place the gallium arsenide wafer processed in step (2) on the adsorption pad mold C for back fine polishing, the adsorption pad mold C is provided with a circular hole C, and the depth of the ...

Embodiment 2

[0048] As a wax-free polishing method of an ultra-thin semiconductor wafer in an embodiment of the present invention, taking a 4-inch finished germanium sheet with a thickness of 135-155 μm and a diameter of 100 ± 0.05 mm as an example, the wax-free polishing method of an ultra-thin wafer in this embodiment is described in detail. instruction of.

[0049] The only difference between this embodiment and embodiment 1 is: (a), in the step (1), the flow rate of the polishing liquid for the rough polishing on the back is (78.5×9-50=650ml / min), the step In (2), the flow rate of the polishing fluid for the rough polishing on the front is (78.5×9-50=650ml / min), and in the step (3), the flow rate of the polishing fluid for the fine polishing on the back side is (78.5× 9-50=650ml / min), in the step (4), the flow rate of the polishing liquid for the fine polishing of the main surface is (2×78.5×9-50=1363ml / min).

[0050] The wax-free polishing method of the ultra-thin semiconductor wafer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com